Naini Papers is making significant strides in minimizing the water consumption, reducing the water usage from 60 m3/tonne of paper to 30 m3/tonne of paper in the last 5 years. In an exclusive interview with Paper Mart, Mr. Pawan Aggarwal, Managing Director of Naini Papers Limited, reveals that the company aims to achieve the 20 m3/tonne of water consumption by 2026 for its agro/ wood based paper mill by increased recycling of the ETP-treated effluent with the help of membrane technology.

Paper Mart: How has your understanding or approach to water circularity evolved over time and how close are you to achieving it?

Pawan Aggarwal: Naini Papers’ motto “Ethically Firm, Environmentally Strong” itself explains the commitment of the industry towards the conservation of natural resources.

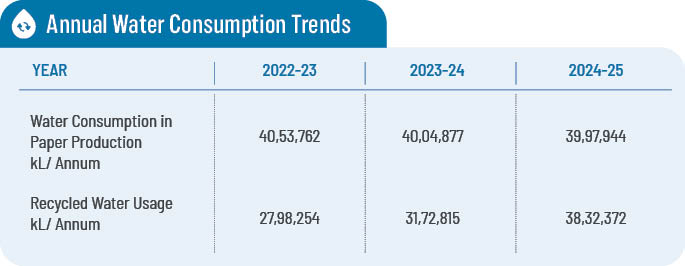

With water being the most precious resource, the company focuses on maximum recycling and reuse of water in the process, thereby reducing the fresh water consumption per tonne of paper. In the last 5 years, the company has made a lot of efforts, minimizing the water consumption and reducing the same from 60 m3/tonne of paper to 30 m3/tonne of paper.

Our mission is achieving the water consumption of 20 m3/tonne of paper by 2026 for agro/ wood based paper mills by increasing the recycling of the ETP-treated effluent with the help of membrane technology.

The company also raises awareness and educates employees about the importance of water conservation by actively involving them in identifying and implementing water saving solutions and suitably rewarding the best ideas in the field of water conservation via the Kaizen approach.

Watch: In Pursuit of Lesser Water Footprint

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)?

PA: Naini Papers has worked intensively on water conservation by continuous improvements in the processes and adaptation of green technologies.

The company has installed efficient IBS showering systems on paper machine wet ends to reduce water consumption drastically. The showering system reduces water consumption from 1900 m3/day to 1200 m3/day, thereby reducing water usage by 700 m³/day.

Moreover, 100% recycling of paper machine backwater to the pulp mill by passing through Saveall and settling in a clear water tank reduces 2200 m3/day of fresh water consumption.

The company has also installed a state-of-the-art DCS based biomethanation plant from Hydrothane (Netherland) for high effluent load drains. The effluent from bagasse wet bulk storage and wet washing is treated in the biomethanation plant before going to ETP. This reduces Chemical Oxygen Demand ( COD ) by 80% and biological oxygen demand (BOD) by 90%. The recovered biogas in the biomethanation plant is used as a fuel in boilers.

The treated ETP effluent is 100% reused for wet washing of raw material and wetting of bagasse wet bulk storage. This process saves 4000 m3/day of fresh water consumption.

Counter-current washing is implemented in the unbleached and bleached sections of the pulp mill, with approximately 70% of counter-current washing achieved in the bleached section. Additionally, gland cooling in the unbleached section is carried out using effluent treated through ETP, contributing to efficient water reuse within the process.

The black liquor generated from the pulp mill is completely incinerated in the chemical soda recovery plant and soda ash is recovered. The foul condensate from the soda recovery plant on ODL washers is further used for pulp washing.

The company has installed the Reverse Osmosis (RO) system followed by the Multi-Effect Evaporators (MEE) and Agitated Thin-Film Dryer (ATFD) systems, having a water capacity of 2000 m3/day.

Lastly, the company delves into the construction of the gabion structures in the rain drains for high recharge of rain water. The catchment area of these nallahs is about 16 km2 which receives an annual rainfall of 1930.20 mm, with an annual rainfall volume poured over it is 30.88 MCM. If 25% of this volume is recharged, it will amount to 7.72 MCM (i.e. 77,20,000 m3) which is approximately twice the annual water withdrawal (39,60,000 m3) by Naini Papers Limited.

The 20 gabion structures have been constructed at the cost of INR 30 lakh and maintained yearly at a cost of INR 6 lakh.

The IBS showering system reduces water consumption from 1900 m3/day to 1200 m3/day, thereby reducing water usage by 700 m3/day.

PM: Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

PA: The company has innovated in two major ways in terms of water conservation. Firstly, the company has installed its first ZLD plant, with a water recycling capacity of 2000 m3/day, after tertiary treatment of ETP treated effluent. The ZLD system consists of 2-stage RO, followed by multiple effect evaporators (MEE) for reject handling, which is further followed by Agitated Thin Film Dryer (ATFD). The reusable water recovery (TDS < 100 ppm) from the complete system is about 90%.

Secondly, the company focuses on RO reject treatment. In this, the rejection from RO-I is again chemically pre-treated before feeding to RO-II which results in higher recovery from RO plant.

Naini Papers’ vision of water conservation is further strengthened by installing the membrane technology system for ETP which is first-of-its-kind in the pulp and paper industry. The total capital expenditure (CapEx) involved for the above system is INR 15 crore and has an operating expense (OpEx) of INR 110/Kl.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

PA: The biggest road blocks for water reuse with respect to technical operations are automation and dosing optimization of pre-treatment, Chloride/ Silica or hardness reduction in the feed effluent, alternate reject handling solutions, and consistent ETP (Aerobic & anaerobic process) operations.

Further cost optimization, with respect to power and RO running operations, has become competitive in the market with respect to paper cost.

The major challenges, with respect to finance, are high CapEx and OpEx cost for implementation of membrane technology. Further, the biggest hurdle with respect to regulatory authorities are stringent effluent discharge norms, and high water usage cost.

The industry is making extra efforts with respect to water conservation which should be rewarded for benchmarking the water reusage rather than decreasing the same at every NOC renewal.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

PA: Industries often need permission to withdraw water from ground and these permissions limit the amount of ground water we can use. So, conservation and efficiency becomes a key part of our water management goals.

Stringent discharge norms drive the industry to invest in advanced treatment technologies and set goals for reducing pollutants. Moreover, strict penalties for violations (environment compensation) make compliance non-negotiable.

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

PA: Investments in water reuse technologies offer intangible benefits, such as addressing societal concerns about conserving water for future generations. Moreover, the working efficiency of the machine is fully utilized by optimizing water usage and ensuring compliance with regulatory norms as directed by the authorities.

The company has installed its first ZLD plant having a capacity of 2000 m3/day after tertiary treatment of ETP treated effluent.

PM: Do you involve technology providers in planning or customizing your water treatment systems? Is there any successful collaboration worth sharing?

PA: We have been involved with technology providers in customizing our water treatment systems as per our planning, since water reuse involves a lot of innovation, especially in the pulp and paper sector.

Over the last 7 years, Naini Papers has innovated intensively in the ZLD treatment process for ETP by standardizing the workable treatment technology and reject handling to maximize the water recovery. Also, we have reduced the OpEx by 50% and are further working on it thus making this technology more cost effective.

Also Read: Emami Paper Mills Boosts Water Efficiency, Increases Recycled Water Usage by 28% in 1 Year

PM: Have you considered or implemented digital twins to simulate, monitor, or optimize your water use? What kind of improvements could such systems bring to your operations?

PA: We have considered implementation of digitalization and data interpretation with respect to water usage and its optimization to some extent. Such systems help in immediate triggering and rectification of fluctuation in water usage for the end users. In the next 2-3 years, we will be in the process to completely implement this technology after overcoming the bottlenecks with respect to the system usage.

PM: How do you see your water use evolving in the next 5–10 years? What would “full circularity” look like in your operations? What kinds of support in terms of technology, partnerships, or policies would help you get there?

PA: Optimal water use will be the foremost concern in the coming years. Achieving full circularity will be our prime goal, however, operations demand the system to be purged at certain intervals to maintain the product quality. The purging time can be reduced by adoption of suitable green technologies.