Innovative GPS navigates shortest route to fiber quality at lowest cost.

Like your Smartphone’s GPS can guide you almost anywhere in the world, the “papermaking GPS” guides you in making the right choices about fiber mix, applied energy, and paper quality. It’s significantly reducing trial and error on your machine and saving time and money.

While it is true that papermakers have considerably more data today to help them navigate their processes, there are still some blind spots. For example, in the stock preparation area even experienced papermakers are “flying blind” in refiner operation. Operator screens do not show how a change in applied power or fiber mix affects stock quality in the machine chest. In most cases, laboratory tests received after the sheet has already been produced are the only way to probe the stock quality. This results in outdated quality measurements that are no longer helpful, as the pulp is already processed with potentially unacceptable quality, resulting in off-grade quality.

While it is true that papermakers have considerably more data today to help them navigate their processes, there are still some blind spots. For example, in the stock preparation area even experienced papermakers are “flying blind” in refiner operation. Operator screens do not show how a change in applied power or fiber mix affects stock quality in the machine chest. In most cases, laboratory tests received after the sheet has already been produced are the only way to probe the stock quality. This results in outdated quality measurements that are no longer helpful, as the pulp is already processed with potentially unacceptable quality, resulting in off-grade quality.

One way to describe the operational settings that produce paper within specification is to run trials with different fibers, additives, and applied power settings and then to determine the corresponding effect on quality. However, on-machine trials can be risky and expensive, and off-machine trials can be inconclusive since the actual production equipment is not used. The ability to predict real-time cause-and-effect in refiner operation does not exist… until now.

Bringing light into the darkness

For many years, a papermaker’s goal has been to have the means of visualizing fiber quality during refiner operation and to see the real-time variation in quality with process changes. In the early 2000s, ANDRITZ developed a proprietary simulation tool, which enhanced the refiner plate selection process leading to energy savings and fiber quality improvements, but it still lacked insight into real-time fiber quality.

“The days of flying blind are now over. ANDRITZ Fiber GPS, software based simulation and optimization tool, brings light into the darkness and allows papermakers to look into stock preparation refiners while in operation,” says Peter Antensteiner – Vice President, LC Refiner Plates, Fiber GPS.

Focus on the big (and small) picture

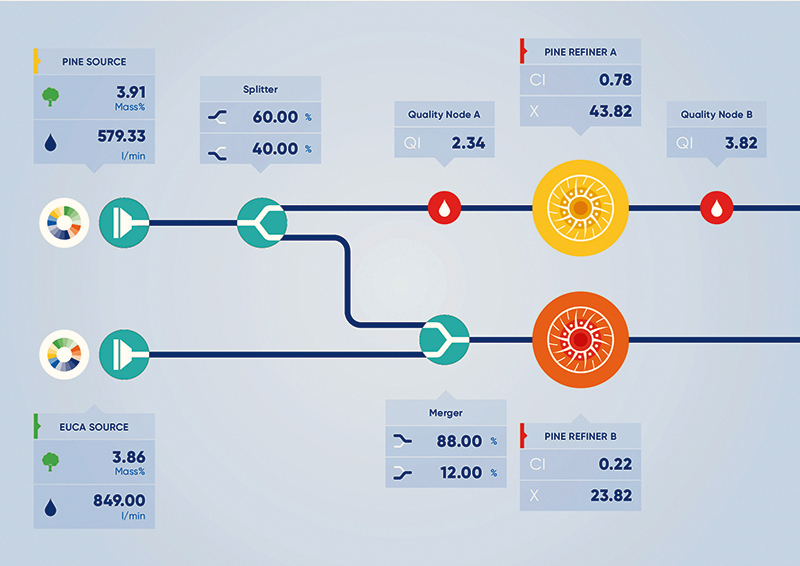

Fiber GPS is the evolution of the earlier simulation tool with fiber quality data models. Instead of focusing only on refining process parameters, Fiber GPS utilizes a statistical quality model, which combines these parameters with fiber quality data. This model uses pulp quality data representing intrinsic fiber quality features such as length, chemical surface composition, and fines content, as well as information about “refinability,” to calculate fiber qualities of refined pulp mixtures. With this expansion of view from individual refiners to system-wide fiber quality development, a user can visualize and understand the quality impact of fiber mix, flow and consistency, power application, and plate design.

By simulating the complete stock preparation area, Fiber GPS allows the user to “deep-dive” into the fiber quality customization process.

Savings potential in a mixed up fiber world

Savings potential in a mixed up fiber world

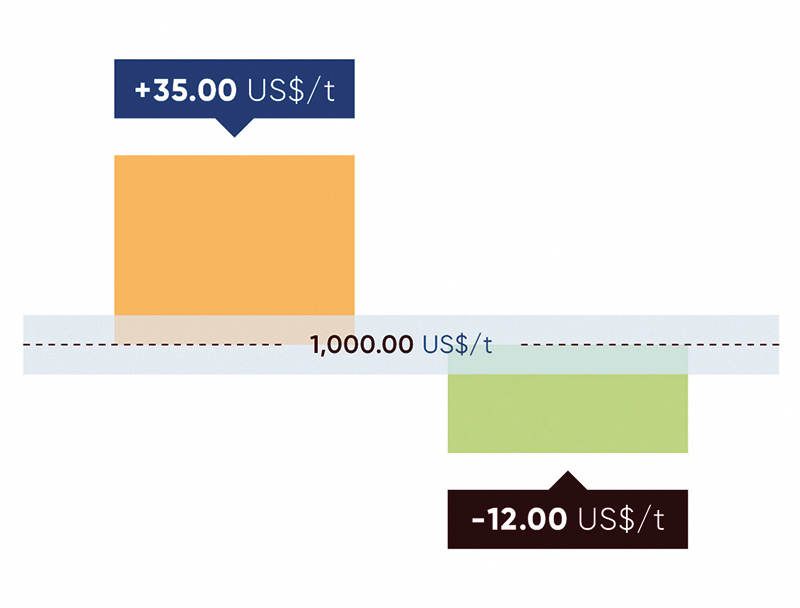

Another breakthrough in Fiber GPS is the ability to predict pulp quality for a fiber mix entering the refiner. Until now, papermakers were able to determine pulp quality for only single fiber types, so this development makes Fiber GPS unique and brings with it a sizable savings potential for customers. With Fiber GPS, operators can confidently make changes to achieve the desired paper quality and avoid on-machine disruptions due to trial and error. Fiber GPS™, sold on a monthly fee basis, helps optimizing the total cost of ownership.

Fiber GPS with ANDRITZ Refiner plates – the comprehensive stock preparation solution

The beating heart of every stock preparation area is its refiners. The core of each refiner is its refiner plates. ANDRITZ plate specialists will be able to support Fiber GPS customers by reducing trial and error via simulation and scenario management. ANDRITZ will be able to optimize plate technology for a customer’s particular system and grade structure for maximized quality effectiveness and reduced total cost of ownership. Fiber GPS expands a papermaker’s view from a single refiner at a time to complete stock preparation area, and the effect of each plate design choice becomes accessible, which maximizes the effectiveness of the plate selection process. ANDRITZ offers various beneficial packages with Fiber GPS including ANDRITZ refiner plates and Refiner service.

Antensteiner concludes, “Savings opportunities are boundless! When market prices for different fiber sources rise, Fiber GPS can reduce total cost of ownership by suggesting a cheaper mix. Also, sophisticated algorithms behind Fiber GPS provide reliable fiber quality prediction over several stages of refining as well as mixing of different refining lines – a true breakthrough.”

“Fiber GPS has an optimization-assist mode that guides operators to a best-case scenario in terms of cost and quality.”

Peter Antensteiner

Vice President – LC Refining

Benefits at a Glance:

- Quality Assurance

Visualize and maintain desired paper grade quality

- Total Cost of Ownership Reduction

Optimize Total Cost of Ownership (TCO) and see historical comparison between real-time and optimized costs

- Fiber Mix Optimization

Discover which fiber mix maximizes savings potential while meeting quality specifications

- Paper Grade Development

Set up and manage quality standards for each paper grade to compare different scenarios

- Refiner Plate Optimization

Browse through ANDRITZ refiner plate library and optimize plate patterns

- Vendor Qualification

Determine the effect different pulps have on paper grades and how to best use specific pulps

Getting Technical

Getting Technical

Automation

Fiber GPS provides real-time, simulation, and optimization assisted operations. It comprises ANDRITZ IDEAS simulation platform as a virtual plant, I/O point communication with DCS for real-time data, Metris historian, and a custom Fiber GPS graphical interface.

Fiber GPS Operating Modes

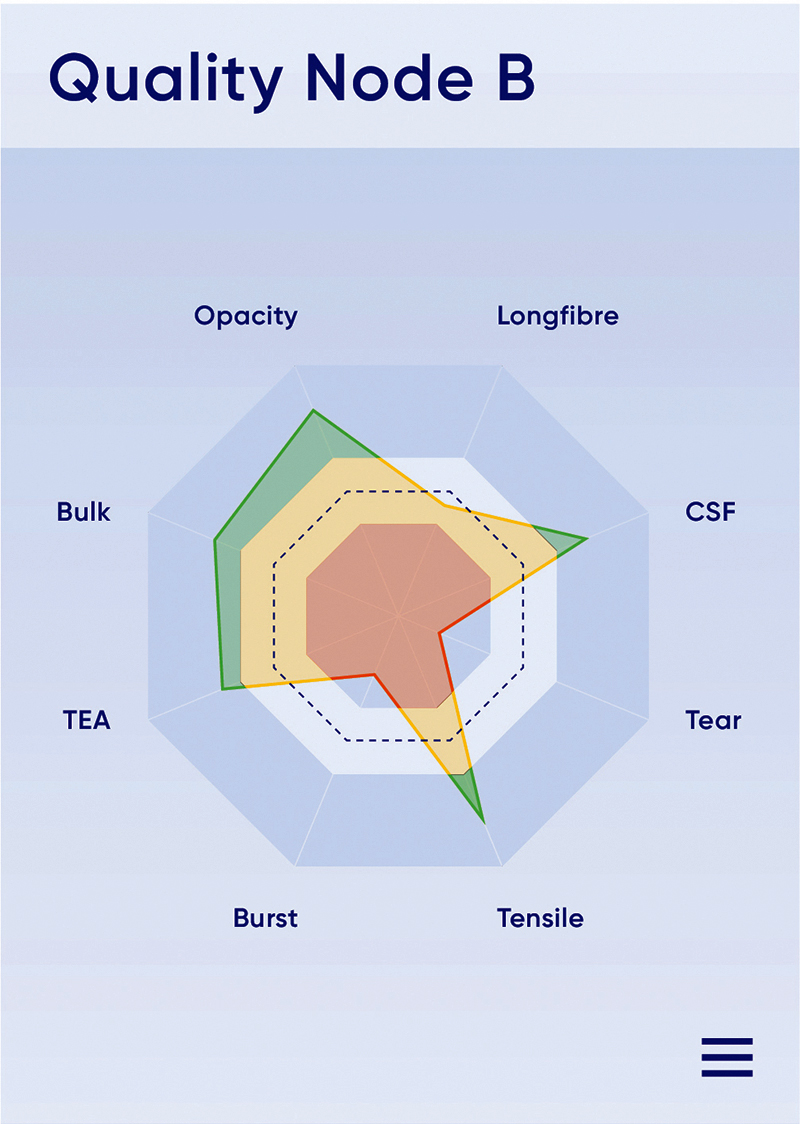

In Real-Time Mode, Fiber GPS receives process parameters directly from the mill, and it allows operators to visualize pulp quality currently being produced within a spider graph and whether the quality meets the desired paper grade specifications. With this information, operators can proactively course correct in real time as needed.

Simulation Mode is an interactive space that lets users manipulate the various process and equipment parameters like flow rate, pulp furnish, power settings, and refiner plates and shows how these changes affect machine chest quality. Operators can save these “what if” scenarios for further analysis and reduce the need for mill trials.

Optimization mode recommends best-case operating conditions without trial and error on the machine and allows the operator to manage the total cost of ownership and fiber quality. An operator can also see a comparison between real time and optimized process conditions, always remaining in control of the process.

Total Cost of Ownership Reduction

To reduce total cost, Fiber GPS considers the refiner power and cost of the various fibers that a mill uses and recommends the most cost-effective fiber mix and power settings that will produce desired sheet quality.

Remote Online Support

Fiber GPS™ is a software-based solution, which is installed at the mill site. ANDRITZ global refiner plate specialists and start up team are able to remotely monitor the system and provide assistance as needed.