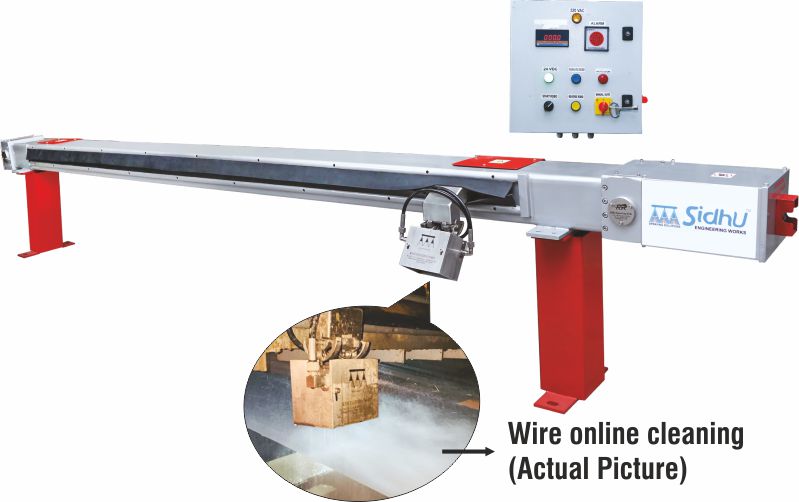

Robo Cleaners – an advanced cleaning system by Sidhu Engineering Works – has been developed for the cleaning of the wire and felt part of the paper machine. Until now, the manufacturer has installed 35 systems which stands testament for the effective performance of the cleaning system.

A paper machine performs three major functions through its different sections – formation of sheet/dewatering of the pulp sheet (wire part); pressing of the paper sheet (press part); and drying of the paper sheet (dryer part). All these functions require some kind of a belt structure to carry the pulp sheet to move forward to other sections. The formation of pulp sheet from pulp is carried out by wire where dewatering on wire (forming fabric made of polyamide). The pressing of the paper sheet is performed on the press part where the felt is used for pressing and absorption of water and the dryer part for the pressing of the web firmly with the dryer to enhance the heat transfer with the help of SLDF (CFM).

Watch: Chadha Papers: Banking on Value Added Products

Although these fabrics require periodic cleaning, in case of press and wire part, there is continuous cleaning is carried out with conventional showers. These conventional showers use ample amounts of water for cleaning the wire and press sections. There are a few solutions for the cleaning of SLDF but these are very costly and less effective. With the current increase in the use of the OCC/recycled fiber, the importance of cleaning is becoming more and more important because of: more fines generation; stickies formation; and other contaminants.

Robo Cleaners

An advanced cleaning system has been developed by Sidhu Engineering Works. The Company has already been providing solutions for wire and felt cleaning with the Robo Cleaning system. So far, they have installed 35 systems, wherein the Company claims that they were are able to decrease water consumption drastically and were able to increase improve CD moisture profile.

The recently developed SLDF cleaner – Robo Dryer Screen Cleaner – is being used successfully on many machines. It is continuous and advanced machinery which is one-of-its-kind and a pioneering ‘Made in India’ product.

How SLDF Robo Cleaner Works and its Significance

Robo Cleaners have a robotic head which oscillates in a linear manner. We’ve tweaked the design of the robotic head in the Robo Cleaners with several nozzles and a different open area in the same head. A jet from nozzles hits the SLDF with high pressure and simultaneously, the vacuum sucks the contaminants and removes these from the system. An air knife is also provided for enhanced cleaning.

In case of wire and felts showers being in continuous or intermittently operational, the conventional showers enable the paper mills to maintain the normal operative conditions and in meeting the optimum process levels. Due to the inadequate cleaning of SLDF, a number of problems can arise such as – stickies, deposits, etc. which can lead to paper sheet breaks. On the other hand, with SLDF Robo Cleaners, the cleaning is much better, resulting in the reduction of paper breaks. Thus, this eventually reduces the downtime in production and achieves the maximization in production levels. Furthermore, the better cleaning outcomes also paves way for better drying rates.

Also Read: CN Automation: Understanding of Process Know-How Helps Creating Efficient Automation Solutions

Benefits of the Robo Dryer Screen Cleaner

To sum up, there are several advantages offered by the Robo Dryer Screen Cleaners such as:

- Reducing the cleaning time and offline cleaning.

- Tremendous increase in the life of the SLDF due to the enhanced cleaning of the SLDF.

- Reduction in the steam consumption as the CFM remains as designed and supplied by the manufacture.

- Increase in the evaporation rate of the moisture in the paper sheet.

- There will be lesser breaks on the paper machine in the dryer part since all the stickies and other contaminants will be eradicated out of the system.

Robo Cleaners will provide all the aforementioned benefits and having a very high payback because the steam economics will be better which implies that any unwanted expenses due to improper cleaning wouldn’t arise. In addition, a new fuel policy – regarding the use of unapproved fuels – is being implemented in Delhi-NCR, around 150 paper mills are affected by it. Thus, it becomes imperative to use the maximum amount of heat from the dryer since the cost of steam has increased.