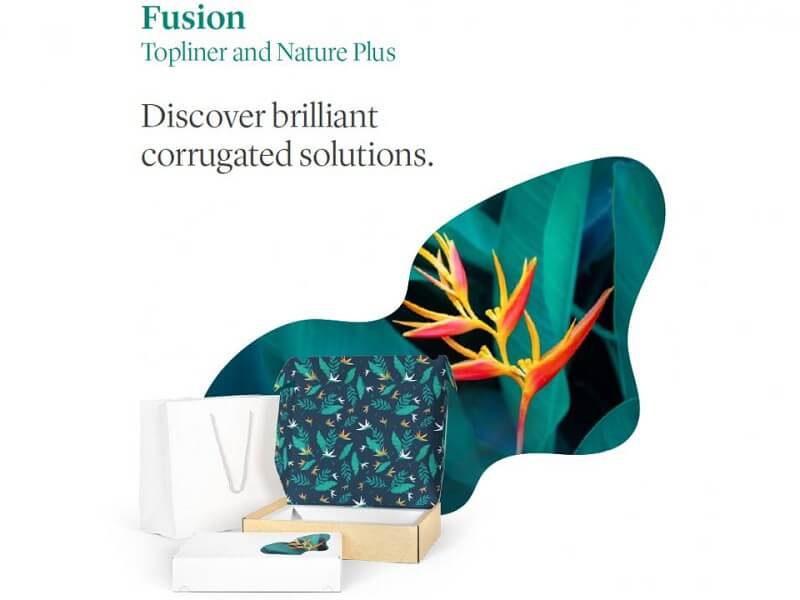

The pulp and paper company designed – Fusion Topliner as an alternative to traditional corrugated liners in the market which are kraft liners and test liners. It is recommended for applications such as premium quality consumer goods packaging and POS displays.

February 4, 2022

Sappi has announced the expansion of its production of Fusion Topliner grade in its flagship mill in Gratkorn, Austria. Fusion Topliner, that is, a white virgin fiber liner for high-quality corrugated packaging, will also continue to be manufactured at Sappi’s Ehingen mill in Germany.

With this expansion, Sappi is not just scaling up its production capacity in the corrugated board business but is bringing production closer to its customers – to assure a sustainable and short supply chain in Europe.

Watch: Paper Mart News Roundup

As an alternative to kraft liner and test liner, Sappi developed its Fusion Topliner, which has now become the most widely used corrugated liner made from pure virgin fiber. It is recommended for applications such as premium quality consumer goods packaging and POS displays as it stands out more than the conventional corrugated liners.

The production of the topliner is now being expanded from the German mill in Ehingen to include Sappi’s flagship mill in Gratkorn. Thus, the available capacities are increased to include the production of Fusion Topliner besides graphic papers. The volume availability is going to be increased month by month to support the expected demand of our customers, and to fulfil large-scale requirements in the corrugated board segment.

Also Read: Sappi and ISBC Develop New Smart Paper With Embedded RFID Chips

Luis Mata, Sales Director Packaging & Digital Solutions, Sappi, explains, “Gratkorn offers the best possible technical prerequisites for the production of our Fusion product. With the investments we have made, Sappi is strengthening its packaging and speciality paper business as well as the Gratkorn mill itself.”