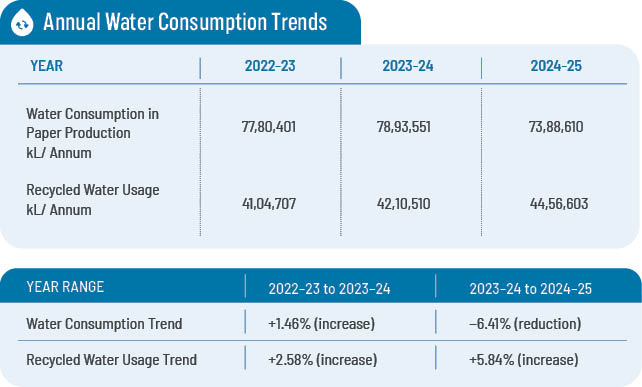

Seshasayee Paper and Boards Limited (SPB), a flagship company of the SPB-ESVIN Group, engaged in the business of manufacture and sale of writing and printing paper, envisions a transition to full water circularity, where every drop of water used in the mill is either reused internally or recovered for secondary applications, in the next 5-10 years. Dr. K. Rajkumar, Chief Manager-Environment, Seshasayee Paper and Boards Limited (SPB), revealed that from 2023-2024 to 2024-2025, SPB achieved a significant 6.41 percent reduction in total water consumption, while recycled water usage increased by 5.84 percent.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

K Rajkumar: Our approach to water circularity has evolved significantly over the four decade. Initially, our focus was on meeting discharge norms through conventional effluent treatment. Over time, with increasing regulatory focus and environmental awareness, we adopted a more integrated and sustainable approach. This includes water minimization at source, internal recycling, and reuse of treated wastewater across various process streams. Today, we are well on the path toward full circularity. The company has a structured and innovative lift irrigation scheme, in which the treated effluent generated from the mill is used for rising sugarcane crops in 2140 acres of dry and fallow lands in the nearby vicinity. The unique tripartite arrangement between the farming community, the sugar industry and the paper mill paved a green revolution making the area adjoining the mill a green cover.

Watch: In Pursuit of Lesser Water Footprint

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)?

KR: We have implemented a robust set of internal water reuse and recovery systems across the mill. Stringent internal norms have also been fixed for consumption of water by individual departments. A high-level water consumption monitoring cell has been constituted to monitor the water consumption by individual departments regularly. All the individual section water consumption is measured and recorded with electromagnetic flow meters. This is being reviewed at shop floor level meetings daily. The production review meetings are also conducted everyday, in which water consumption is reviewed and proposals, if any, for further reduction of water consumption are also discussed and implemented.

The total water audit studies the quality and quantity of water from each section. It also identifies areas for replacing fresh water by recycling the treated effluent at source. The SRP evaporator primary condensate water is sent to the condensate polishing unit and used in boiler feed, along with DM water. The entire evaporator secondary condensate is reused in the bagasse pulp mill and in caustisisers by replacing fresh water. Reuse of paper machine non-colored white water is treated in a separate clariflocculator and the treated water is used for RDH pulp dilution replacing fresh water.

The colored wastewater from MFI, MG and Yankee machines is treated in a separate clariflocculator and reused as input in ETP, for wood log washing, and in bagasse preparation. All the utility filters back wash water is recollected in raw water sump and treated for reuse. Utility RO and UF reject water is diverted to raw water sump, instead of going to drain. In RDH plant pump sealing water is collected, filtered and reused. All the machine back water after treating in save-all is taken back to the system. About 38-40 percent of water is collected at source and recycled back-to-back to the suitable process. The shower nozzle’s size is reduced from 1mm to 0.8 mm in the VHP shower to reduce fresh water. The filtrate from the wet lap machine is recycled back to process.

Continuous efforts are being made by the company to further reduce fresh water consumption. The present water consumption is 38-40 m3/ton of paper.

PM: Which technologies or solutions have you found most effective in reducing freshwater consumption or increasing internal recycling?

KR: Technologies such as disc filters, pressurized save-alls, closed-loop vacuum pump sealing systems and high-consistency washers have significantly reduced water consumption. Besides, we have installed high-efficiency poly disc save all in PM 4 & 5 for back water recycling and fiber recovery, de-collator for vacuum pump seal water recycling, and separate treatment for white water from PM 4 & 5 in a clariflocculator with coagulant dosing.

Recycling of bagasse is done through a thickener filtrate. Collection of RO plant UF and RO reject water in raw water sump aids further treatment. We have installed a system for reuse of MF1 and MG paper machine save-all clarified water in wire showers, edge knock off showers, and sheet knock off showers in paper machines.

We have installed a new save- all system in the Yankee paper machine for fiber recovery and fresh water reduction. There is a sealing water collection system for recycling back to the process. The raw water is collected in clarifier underflow for further treatment in the HRS clarifier with chemicals. We have installed a sealing water collection system comprising disc filters and mist cooling system for cooling secondary condensate for water recycling. Diversion of all filter backwash water from utility to raw water tank is done for further treatment and reuse. All these technologies help us in reducing our specific water consumption substantially.

While we currently operate under a partial zero liquid discharge (ZLD) framework, several sections of our operations already function with closed-loop water use.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

KR: The primary challenges include the high capital and operational costs of ZLD systems, especially for membrane maintenance and sludge handling. Technical complexities such as membrane fouling, reject management, and scaling in evaporators also pose hurdles. Space limitations in older parts of the plant restrict the easy addition of large treatment units. Despite these challenges, we are committed to progressing steadily toward higher reuse levels.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

KR: Regulatory policies at both state and national levels have played a crucial role in shaping our water management strategies. We are required to comply with stringent water and environmental norms. These include maintaining water quality standards, operating under recycling frameworks, and submitting regular environmental performance reports. National sustainability directives, including ESG disclosures and Charter requirements, have accelerated our internal water-saving initiatives by linking environmental performance with compliance credibility and business continuity.

The mill has divided the treatment of mill wastewater into three categories – low BOD effluent, medium effluent, and high BOD effluent.

In low BOD effluent, white water from all paper machines is treated separately in clariflocculators with necessary coagulant addition for recycling back to process.

In medium BOD effluent, effluent from recovery, power house, pulp mill and anaerobic lagoon outlet are collected in the equalization tank and pumped to the primary clarifier of 180 feet dia with 14 feet SWD. The suspended particles settle down, taken to a belt filter and filtered under vacuum. The removed primary sludge is consumed by the mill board manufacturers. The primary overflow from the clarifier is taken to an aeration basin fitted with 12 numbers of 50 HP twin lobe surface aerators to provide dissolved oxygen required for the activated sludge process. The MLSS, F/M ratio and dissolved oxygen is maintained for efficient working of the process.

This is followed with a secondary clarifier to settle the MLSS and recycled back to aeration. A portion is treated in the sludge thickener and wasted after processing through decanter centrifuge. Spill control systems are installed in recovery and pulping areas to collect the liquor spills and recycle the same to process. The treated effluent is monitored by a real time data monitoring system connected to TNPCB and CPCB 24×7. The clarified final treated effluent is disposed to lift irrigation societies where the treated effluent is used for raising sugarcane and tree crops like Casuarinas, Eucalyptus etc. Final treated effluent is monitored by TNPCB personnel and the results are within the stipulated standards prescribed. Once in a year this is verified by a NABL accredited laboratory.

In high BOD effluent, the bagasse waste water enriched with high COD is filtered in side hill screens with screw press for the removal of suspended solids. It is subjected to anaerobic treatment in the anaerobic lagoon along with the high COD foul condensate from chemical recovery. The treatment efficiency is 90 percent reduction of BOD and COD. The biogas generated is collected in a Polyurethane (PU) membrane balloon and burnt in the rotary lime kiln replacing part of furnace oil.

Also Read: Kuantum Papers: Driving Water Circularity and Sustainability

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

KR: Year after year, the water consumption of the mill has reduced due to consideration of the fact that water is precious.However, increasing the backwater cycle volume within the current system presents significant challenges in maintaining the desired process water quality, especially in an integrated pulp and paper mill. This often leads to reduced process efficiency, increased chemical consumption, and a corresponding rise in Total Dissolved Solids (TDS) in the treated effluent. While we have made considerable investments in water reuse systems, these efforts have not resulted in direct cost savings. Globally as well, Zero Liquid Discharge (ZLD) is not widely implemented across the pulp and paper sector, and where implemented, it is often limited to partial or source-specific treatment. Only a few mills have adopted it on a limited scale. In conclusion, the scale, operational complexity, and economic viability of ZLD remain key constraints. However, we remain committed to ongoing evaluations and pilot trials to identify a sustainable, techno-economical solution that aligns with our long-term environmental goals.

Technologies such as disc filters, pressurized save-alls, closed-loop vacuum pump sealing systems and high-consistency washers have significantly reduced water consumption.

PM: Do you involve technology providers in planning or customizing your water treatment systems? Any successful collaborations worth sharing?

KR: We actively engage with technology providers such as UNIDO and CPPRI, along with environmental consultants, during the planning, selection, and customization of water treatment systems. Successful collaborations include pilot testing of advanced RO membranes with improved fouling resistance, integration of real-time monitoring systems with digital dashboards, and process optimization in coordination with global Engineering, Procu-rement, and Construction (EPC) firms. These partnerships have not only enhanced the performance of our systems, but also ensured scalability and adaptability to changing operational loads. We are coming up with UNIDO membrane filtration technology. Trials are already underway with recycling of the EOP filtrate to recover chemicals as well as water with membrane technology to meet any issues in future and make it fit for process applications.

PM: How do you see your water use evolving in the next 5-10 years? What would “full circularity” look like in your operations? What kind of support in terms of technology, partnerships, or policies would help you get there?

KR: Over the next 5–10 years, our water usage strategy is expected to shift significantly towards greater water recovery, reuse, and recycling. However, in integrated pulp and paper mills, increasing the backwater cycle volume introduces several operational challenges. The elevated recirculation of water often leads to the accumulation of dissolved solids and other contaminants. This can degrade the process water quality, adversely affecting pulp brightness, sheet formation, and chemical interactions. The impact includes a decline in process efficiency, higher chemical consumption, increased fouling and corrosion risks, and ultimately, a significant rise in Total Dissolved Solids (TDS) levels in the wastewater.

Globally also ZLD is not well established. Very few mills have done it partially for source treatment in limited areas. To conclude, its scale, complexity and economical viability are the present constraints. However, it will not restrict our efforts to carry out study trials to find a techno economical solution. Meanwhile we will continue with our water conservation.

PM: Have you considered or implemented digital twins to simulate, monitor, or optimize your water use? What kind of improvements could such systems bring to your operations?

KR: Digital twins can help us predict equipment performance, manage system loads in real time, and improve the overall efficiency of our water reuse systems. When implemented, such systems will enable us to move from reactive to predictive water management, enhance data transparency, and support faster decision-making with real-time feedback loops. Between 2022–2023 and 2023–2024, there was a slight increase of 1.46 percent in water consumption for paper production. This marginal rise can be attributed to higher production volumes, process optimization activities, and the commissioning of new equipment that initially required additional water for stabilization and testing. However, during the same period, the usage of recycled water improved by 2.58 percent, reflecting our commitment to enhancing internal water reuse systems.

Moving from 2023-2024 to 2024-2025, we achieved a significant 6.41 percent reduction in total water consumption, primarily due to the successful implementation of advanced water-saving initiatives, such as white-water recovery, process condensate reuse, and further strengthening of our monitoring systems. Additionally, there was a notable 5.84 percent increase in recycled water usage, indicating a shift towards circular water practices within our operations. These improvements underline our continuous efforts towards achieving greater water sustainability and reducing fresh water consumption.