World Water Works specializes in the combination of Moving Bed Biofilm Reactor (MBBR) technology, Dissolved Air Flotation & DEMON® technology for advanced wastewater treatment

World Water Works is a manufacturer of specialized process and waste water treatment technologies focused on performance, flexibility and longevity designed to yield clean water and recover energy and to achieve other resource recovery. Its integrated waste water treatment solutions are designed to perform on the widest range of influent conditions possible while still yielding the absolute best water quality.

Dissolved Air Floatation (DAF):

World Water Works (WWW) is a leader in DAF technology. The World Water Works’ Ideal DAF can be effectively used to remove TSS, FOG, BOD, COD and other resources and/or resources from a liquid stream.

DAF’s Proprietary and Patent Pending features include:

1. Cross Flow Design – Results in higher residence time and lower footprint

2. Progressive Water Extraction technology – Results in higher removals and lower footprint

3. Plate Separation technology ‐ Provides higher surface area for solids removal

4. Regenerative Turbine System ‐ Creates very fine bubbles of 5‐15 microns resulting in high removal efficiency, lower power requirement and lower chemistry

5. Cone Bottom Sludge Removal – Provides easy sludge removal

6. Polypropylene Design – Provides resistant against corrosion

Dissolved Air Flotation (DAF) technology is the process where suspended solids, oil & greases, and other insoluble impurities are separated from water slurries by a process of dissolving air into water under pressure. Micro bubbles are formed under pressure which interacts with the particles to cause them to float to the surface of a vessel where they are skimmed and separated. World Water Works developed a remarkable DAF – the IDEAL DAFTM. This technology is now in its 7th generation over a short 14 year span.

The Ideal DAF system was tested side by side several of the most well‐known DAF’s in the market. It completely outperformed the competition. Dramatically higher removal efficiencies, lower operational costs, smaller footprint and a longer life‐span make the Ideal DAF technology revolutionary in the marketplace.

MOVING BED BIOFILM REACTOR TECHNOLOGY (MBBR)

Moving Bed Biofilm Reactor MBBR process is a state‐of‐the‐art fixedfilm (or attached growth) biological process used for wastewater treatment both municipally and industrially for BOD removal, nitrification and de-nitrification. It offers several advantages over the traditional Activated Sludge Process. Due to its low cost & high treatment quality it is preferred over MBR technology in most cases.

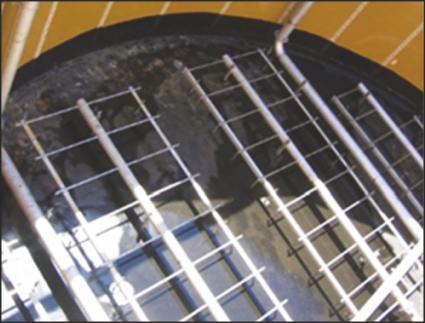

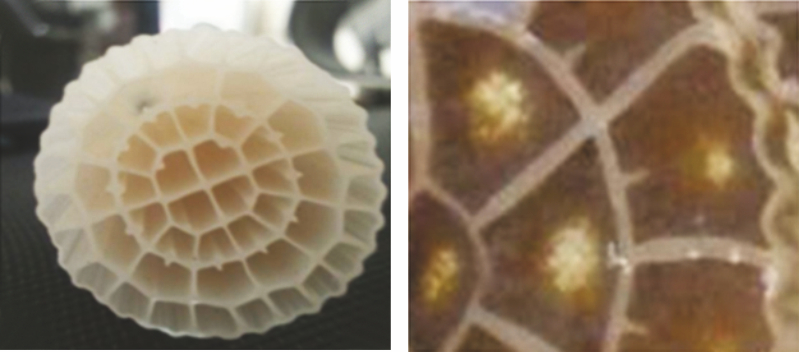

A Moving Bed Bio-film reactor MBBR consists of a tank with submerged but floating plastic media. Plastic media provides abundant surface for bacterial growth. Biomass grows on the surface as a thin film & degrades the organic matter resulting into BOD removal and /or nitrification. Coarse bubble diffusers are used to maintain DO in the tank & screens are used on the downstream wall to retain media. No sludge recycle is required for this process.

For de-nitrification, anoxic Moving Bed Bio-film Reactor MBBR tanks are used which uses submersible mixers to keep media in suspension, no requirement of diffusers & air supply. In case of high BOD’s, MBBR can be used as a Roughing Reactor to shave off 60‐80% BOD which consequently reduces load on the downstream ASP & also reduces footprints. WWW is a leader in MBBR technology and has installed numerous wastewater treatment plants using MBBR technology

Features of Ideal MBBR:

1. Robust: Stable under shockloads

2. Efficient: Low solids generation low polymer use

3. Compact: Smaller footprints

4. Cost: Low capital cost than ASP & MBR

5. Flexible: Can be used flexibly for up-gradation of treatment plant

6. Trouble Free: Easy to operate, automatic sludge wasting, No return sludge, No MLSS, No media clogging

THE ANAMMOX BASED DEMON PROCESS

Presence of high concentrations of ammonia in effluent causes a continuing problem for treatment plants. World Water Work’s DEMON® can be used for Deammonification. It is a patented and patent pending biological process used to remove nitrogen from wastewaters containing high ammonia concentrations (> 200 mg/l).

Features of DEMON:

1. Requires 60% less energy

2. Uses ammonia oxidizing bacteria and anaerobic ammonium oxidizing bacteria (anammox) to efficiently and reliably remove ammonia from wastewater

3. 90% less sludge

4. Patented & patent pending biological process used to remove high ammonia concentrations (> 200 mg/l)

5. Less energy consumption & less sludge generation leads to

a. Reduction in costs

b. Environment friendly

c. Low carbon footprints

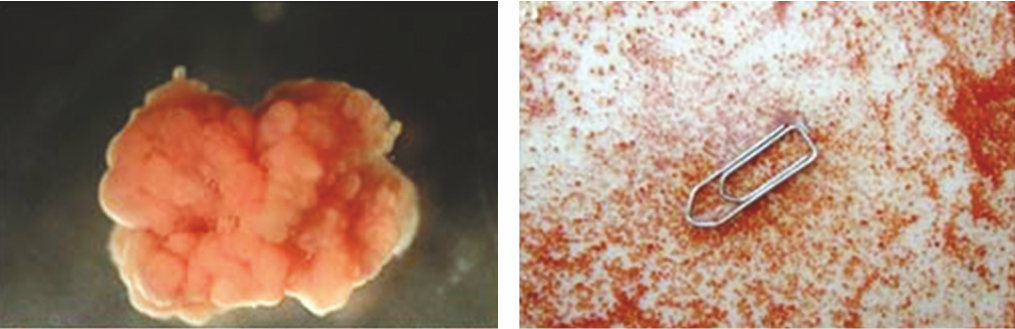

The true key to World Water Work’s success is the anammox based DEMON patented control strategy and patent pending biomass separation device, which maintains appropriate, levels of both AOB and anammox bacteria. The biomass separation device decouples the SRT to allow for two very different bacteria ‐ AOBs and Anammox to thrive. This provides great system resilience and lessens the need for oversight and maintenance. WWW holds exclusive licenses from DEMON GmbH for DEMON applications in USA and India. The process was nominated for United Nations (UN) Most Energy Efficient Project Award.

In the field of deammonification and nitrogen removal, World Water Works is working closely together with its Swiss partner DEMON GmbH.