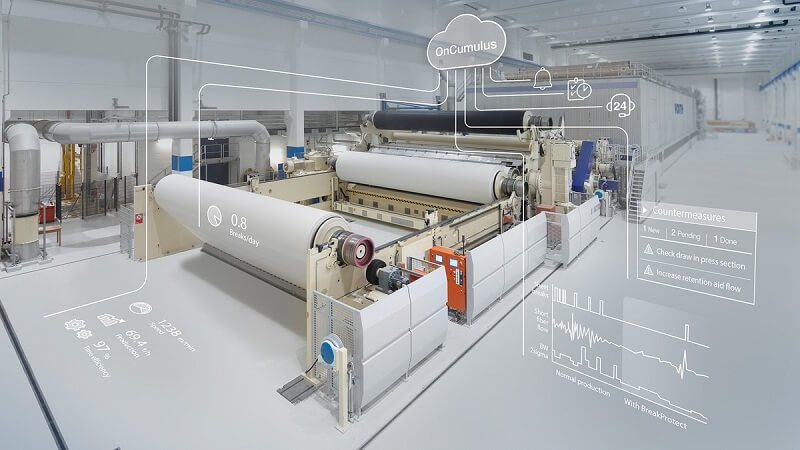

The three digital applications are designed to optimise production in paper mills – OnEfficiency.BreakProtect, OnView.VirtualSensorBuilder and OnView.MassBalance, the three new apps on the IIoT platform OnCumulus.

December 21, 2021

Voith is expanding its modular Papermaking 4.0 portfolio designed to individually optimise production with the leading digital industrial applications. The machinery manufacturer is introducing –OnEfficiency.BreakProtect, OnView.VirtualSensorBuilder and OnView.MassBalance, the three new apps on the IIoT platform OnCumulus.

The new digitalization solutions feature the highest safety standards, are quick to install, and are easy to use. The technologies have already been successfully implemented in several plants worldwide. Due to the process optimisations and lower resource consumption, the applications often pay off in less than a year and pave the way to the digital paper mill.

OnEfficiency.BreakProtect: Detect, Understand and Prevent Paper Break Causes

The IIoT platform OnCumulus has already established itself as a central hub for data from multiple sources for numerous paper manufacturers. OnEfficiency.BreakProtect uses artificial intelligence to analyse the process data bundled in OnCumulus. Thereby, the innovative solution automatically detects various critical process conditions that can lead to breaks. This allows the development of specific countermeasures and the reliable prevention of tear-offs.

Jürgen Käser, Director of Process Applications at Voith, says, “Among other things, we were able to use OnEfficiency.BreakProtect to identify increased dirt and starch agglomerate loads – for which there is no measurement data at all – at the SpeedSizer pulper.”

Watch: Paper Mart News Roundup

OnView.VirtualSensorBuilder: Calculate and visualize quality parameters quickly and easily using virtual sensors

“With OnView.VirtualSensorBuilder, it only takes a few hours for a new soft sensor to be ready for use,” says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. “Previously, this required a time-consuming and costly process of several weeks.”

Once installed, operators can use OnView.VirtualSensorBuilder to continuously calculate, visualize and control relevant quality values, such as strength values, in real-time. Combined with OnCumulus.Suite, the digital application identifies critical values and provides preventive warnings, allowing personnel to make immediate improvement adjustments. The solution thus increases process stability, enables compliance with desired quality standards, reduces raw material costs, and minimises waste.

OnView. MassBalance: Visualize and reduce fiber losses in stock preparation.

OnView.MassBalance maps the current stock flows in an intuitive Sankey diagram and provides information on deviations that are no longer within the standard range. Thus, it leads to targeted process optimisation in stock preparation and also enables centralized knowledge management.

With the help of OnView.DigitalEye, the accuracy of OnView.MassBalance can be increased even further. The innovation makes it possible for the first time to analyse recovered paper quality even before stock preparation with the help of artificial intelligence. The award-winning AI application OnView.DigitalEye is currently undergoing final testing as part of pilot installations at national and international customer sites and is expected to be available starting next year. Another application that will be launched in 2022 is OnView.Energy from Voith. The app visualises and analyses energy consumption and CO2 emissions in production.