“We have made a huge investment in upgrading the plants and using the latest technology has helped the company to increase the production in both the plants from 1,86,000 MTPA to 2,44,000 MTPA”

Gayatrishakti Paper & Boards Limited (GSPBL), started in 1996, is a leading manufacturer of a range of premium grades of packaging boards and kraft paper. Their products are made out of 100 percent recycled waste paper and are completely biodegradable. The company sets out to undertake various innovations in both the product-development side as well as in manufacturing processes on a consistent basis. Presently, GSPBL has invested in developing a 500 TPD brand-new pulp mill from the world-renowned ‘Kadant’ technology implemented and is currently under final trial-run.

In an interview with Paper Mart, Mr. Gajendra N. Agarwal, Managing Director, Gayatrishakti Paper & Boards Ltd., enlightens us about the business journey of the company, the manufacturing capabilities along with the infrastructure of their production facilities at Vapi and Sarigam in Gujarat, and the enabling factors to process a wide range of packaging board grades. Further, he also outlines the trends in the packaging industry and the future plans of the company.

Paper Mart: Could you please take us through the journey of Gayatrishakti Paper & Boards Ltd. and the notable milestones so far?

Gajendra N. Agarwal: Gayatrishakti Paper and Boards Ltd. started its business as a packaging paperboard manufacturing company with its head office in Mumbai and two manufacturing facilities in Vapi and Sarigam, Gujarat. The company was founded by me in September 1996. Mr. Nikhar Agarwal, the second-generation in the business, is also into the day-to-day business of the company and is currently the Executive Director.

The company manufactures premium quality duplex boards and kraft paper from 100 percent recycled waste paper pulp and has an installed capacity of 1,08,000 MTPA and 1,44,000 MTPA. In fact, we are one of the leading manufacturers of duplex boards and kraft paper in India. We constantly upgrade our manufacturing facilities with the latest technologies in order to manufacture superior quality duplex boards and kraft paper.

PM: Please describe the manufacturing capabilities of the company along with an overview of the infrastructure of the unit. Has there been any expansion at the company in the recent past?

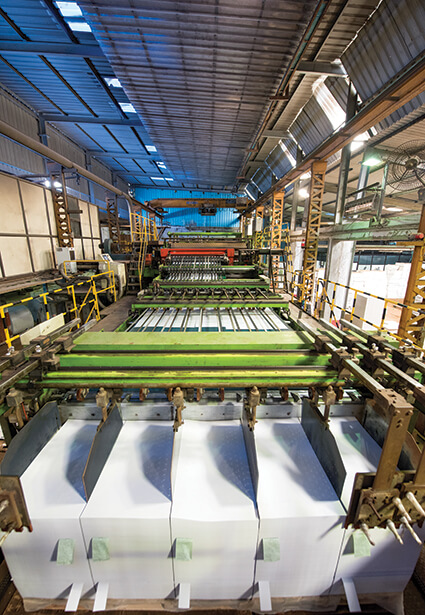

GNA: Initially, the company had one manufacturing facility of the duplex board with a production capacity of 96,000 MTPA and product range from 230 GSM to 500 GSM. The management felt the need to enter in kraft paper packaging segment and thus, the company established a kraft manufacturing facility in 2013 at Sarigam, Gujarat. The project was completed within a span of 18 months and started commercial production in June 2015 with a production capacity of 90,000 MTPA. At the kraft facility, we manufacture kraft paper in the range of 18 BF to 35 BF. It is one of the largest kraft-producing plants in India on a single machine with more than 12,000 MTPA. The company has enhanced infrastructure at both the manufacturing facilities at Vapi and Sarigam. The use of the latest technology at both the manufacturing facilities helps in improving the quality of the finished product. The company has a 4MW captive power plant at both facilities. We have made a huge investment in upgrading the plants and using the latest technology that has helped the company to increase the combined production capabilities in both the plants from 1,86,000 MTPA to 2,44,000 MTPA. In the future, we intend to increase the production capacity in both plants from 2,44,000 MTPA to 3,00,000 MTPA by FY23.

There has been a growing interest from all stakeholders to make packaging more sustainable and environment-friendly… The growth of this (paperboard and packaging) market is dependent on the demand for folding cartons and corrugated boxes products in the e-commerce packaging sector.

Watch: Paper Mart News Roundup

PM: Kindly describe the product portfolio of Gayatrishakti Paper and Boards. Also, shed some light on the kind of clientele, i.e. the different brands served by the Company.

GNA: Our Company manufactures duplex board and kraft paper at its manufacturing facilities at Vapi and at Sarigam in Gujarat. The range of the duplex board is from 230 GSM to 500 GSM and the range of kraft paper starts from 18BF to 35BF. We sell the product through a network of dealers and distributors. Due to our leverage on technology, the quality of our product has been consistent over the years and it has been widely accepted in the domestic and international markets. Our end-users are leading companies in the segments such as – MNCs, FMCGs, pharma, and e-commerce players.

PM: Outline the factors which enable you to process a wide range of grades in packaging boards, while ensuring cost efficiency and enhanced product quality.

GNA: Investment in the right technology and competent workforce are the key factors that enable us to process a wide range of grades in packaging boards with cost efficiency and enhanced product quality. We have the best automation system from renowned vendors in the industry. We also have a competent and loyal workforce and executives at all levels that are well trained for their roles and are given individual responsibilities in their respective areas.

PM: Rising consumer awareness and adoption of sustainable materials have rapidly increased in the past few years. How would you describe the impact of this trend on the Indian paper and paperboards market?

GNA: Consumers’ attitude towards minimising the use of plastic has changed the attitude of the paper and packaging industry over the last decade. With the ban on plastic by governments and public authorities around the world, the demand for packaging paper has increased significantly over a period of time and is expected to increase at a steady pace in the future. There has been a growing interest from all stakeholders to make packaging more sustainable and environment-friendly and paper is considered as the most environment-friendly material available.

Impact on Indian paper and packaging industry

The packaging industry in India is growing rapidly, and it is spanning across various end-user segments such as food and beverages, healthcare, hygiene, and home care, among others. Strong favourable demographics aside, factors such as growing disposable income levels, increasing consumer awareness and demand for processed food, and the multinational giants taking rapid strides in the food, beverages, e-commerce, and pharmaceuticals space, are the key drivers impacting the growth of paper and paperboard packaging industry. The growth of this market is dependent on the demand for folding cartons and corrugated boxes products in the e-commerce packaging sector. Moreover, the market is segmented by the product and end-user verticals. Its end-user segment is further segmented by food, beverage, healthcare, personal care & household care, hardware & electrical products, other industries.

PM: Describe your initiatives for attaining superior quality, and enhancing efficiency in the overall production operations

GNA: We have always believed in adopting the latest technology for attaining the superior quality of both the products viz. coated paperboard and kraft liner board. Our company has continuously undertaken various innovations from time to time in both the products and manufacturing processes and has successfully implemented them so as to provide premium quality in the packaging market as well as enhance efficiency in the production operations.

Various technologies such as the introduction of blade coating in the coated paperboard to get the highest printing results, adding a hot disperser system in the kraft plant to make the final product of kraft paper specks- and smell-free and adopted jet cooking system for starch spray in kraft has made possible to provide the superior quality. Presently, our company has invested in developing a 500 TPD brand-new pulp mill from the world-renowned ‘Kadant’ technology implemented and is currently under final trial-run. This is projected to further enhance the capabilities in attaining more superior quality and enhancing efficiency in the overall production operations in the kraft division of the company.

In the future, we intend to increase the production capacity in both the plants from 2,44,000 MTPA to 3,00,000 MTPA by FY23.

Also Read: PACK-A-BOO – Paper Packaging an Answer to Sustainability Issue

PM: E-commerce packaging is swiftly growing at an enormous pace within the packaging industry – in this respect, how rigid is packaging positioned in the industry?

GNA: The retail e-commerce packaging market is growing promisingly, with the rapid growth in the online shopping ecosystem. Moreover, changing lifestyles of people led by rapid urbanisation, mainly in the developing regions, augment the demand for retail-e-commerce packaging solutions. The increasing consumption of retail-e-commerce packaging materials fosters the retail e-commerce packaging market growth. With the spurring rise in the overall retail industries worldwide, the market is projected to garner immense gains over the next few years.

The Indian e-commerce packaging market was valued at USD 13.8 million in 2020, and it is expected to reach USD 1109.26 million by 2026, registering a CAGR of 13.8 percent during the period of 2021-2026. Owing to the rising population, increasing income levels, changing lifestyles, and growing economy, the demand for e-commerce packaging is growing in India. The country is focusing more on sustainable solutions, which is increasingly becoming a business imperative. With the growing awareness, the requirement for eco-friendly and sustainable packaging is steadily on the rise. With several billion parcels delivered every year, the threat of packaging waste is increasing due to which, the need for recyclable packaging material is on the rise.

Many e-commerce companies are focusing on sustainable packaging solutions to reduce plastic waste and move toward paper-based packaging. Corrugated boxes are very common and widely used packaging materials for the e-commerce industry in the apparel segment, as the material is very strong and highly durable. Accelerated demand for packaging boards for online purchases is expected on account of the COVID19 pandemic. The market for packaging boards is likely to grow 9-10 percent annually in India, compared with around four percent globally.

Presently, our company has invested in developing a 500 TPD brand-new pulp mill from the world-renowned ‘Kadant’ technology… This is projected to further enhance the capabilities in attaining more superior quality and enhancing efficiency in the overall production operations in the kraft division.

PM: What are the future plans of Gayatrishakti Paper & Boards Ltd?

GNA: At present, the company is focused on increasing the production capacity and as a result thereof, the current installed capacity of the company is 2,50,000 MTPA of both coated paper board and kraft liner board. The company has already undertaken the CapEx program to enhance the capacity to 3,00,000 MTPA where the major capacity enhancement is proposed in the Kraft division. Developing a 500 TPD brand new pulp mill from the world-renowned ‘Kadant’ technology is under final trial-run so as to enable us to get better quality with required quantum more pulp presently which will further add in attaining more superior quality and enhancing efficiency in the overall production operations in the Kraft division of the company. The company is also in the process to develop premium products in near future to cater to the increased demand for products, mainly ‘white top kraft liner board’ and ‘kraft pulpboard’.

The company has an inbuilt manufacturing facility to produce uncoated white top kraft liner board and is shortly going for trial-run production so as to get a response from both domestic and international markets. In addition, the company is also planning for manufacturing of partial quality of value-added product viz. kraft pulpboard mainly required in the premium segment of corrugated boxes. Presently, such kraft pulpboard is being manufactured in very small quantum in India and the balance requirement is being met through import sources.

Further, the company aims to replace imported kraft pulpboard with Indian kraft that will match international standards and quality to promote domestic product usage in India. Both the products are mainly used in the premium segment of packaging and the demand in both domestic and international markets is growing gradually.