The machines feature Metris – ANDRITZ digital solutions – which allow for remote assistance during commissioning and start-up as well as improved operation.

June 17, 2021

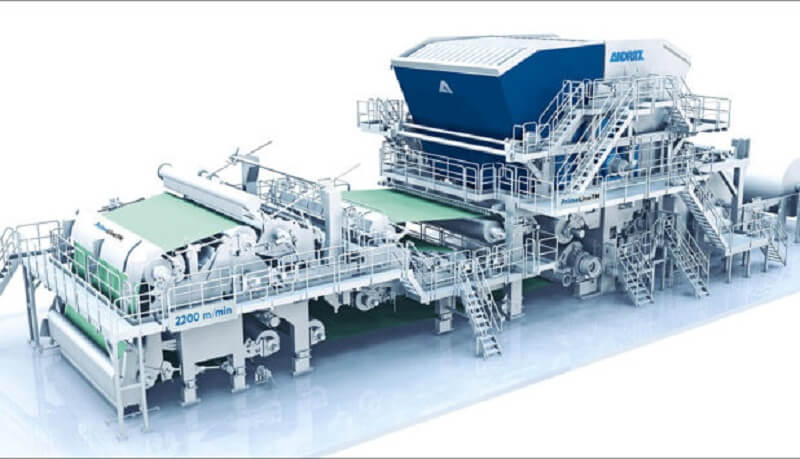

ANDRITZ presents two new tissue machines with a design speed of 2,200 m/min for high production capacity:

– PrimeLineTM S 2200 with 2.6 to 2.85 m width at reel

– PrimeLineTM W 2200 with 5.4 to 5.6 m width at reel

Watch: Paper Mart News Roundup

All proven ANDRITZ key components can be installed, like the PrimePress XT shoe press for gentle dewatering and high nip-loads, the PrimeDry Steel Yankee for energy-efficient drying, the PrimeDry HeatRecovery re-evaporation system for returning energy to the production process, or the PrimeDry Hood ST for steam-heated drying instead of using more expensive gas heating.

The new machines feature Metris – ANDRITZ digital solutions – which enable remote assistance during commissioning and start-up as well as improved operation. With the services offered by ANDRITZ at its Metris Performance Centers, tissue mills are able to benefit from individual and fast customer service by using the Metris UX Platform for optimization of production processes, troubleshooting by operators and decision-making support.

Also Read: Andritz Successfully Starts Up an Innovative Reject Handling Line at Sun Paper Savannakhet

Günter Offenbacher, ANDRITZ Sales Director for Tissue and Drying, explains: “Based on our long-term experience and proven expertise in tissue machines, the design of the new machines has been updated with the latest technologies. With the new high-speed machines, we can offer an innovative concept for dry-crepe tissue machines with high production efficiency for every customer need. Our comprehensive product portfolio ranges from high-performance machines with speeds of up to 2,200 m/min down to efficient compact solutions for smaller production capacities.”