The novel technology aims to capture carbon dioxide from pulp & paper mill flue gas, along with aquaculture wastewater, and convert them into algae-based protein for aquafeed pellets (fishfood). The utilization of algae as aquafeed will also boost greenhouse gas emission reduction.

Jan 3, 2025

A team of researchers at Auburn University are developing a novel technology that converts pulp and paper mill flue gas (carbon emissions) and aquaculture wastewater into algae-based protein for aquafeed pellets. In short, they’re turning pollution into fish food!

Peter He, the Uthlaut Endowed Professor in the Department of Chemical Engineering, is principal investigator (PI) on the U.S. Department of Energy (DOE)-funded, USD 2.5 million (approximately USD 3.2 million with cost share) project, “Intensified and Energy Efficient Cultivation, Processing, and Conversion of Flue Gas Produced Algal Biomass to Aquafeed.”

Watch: In Pursuit of Lesser Water Footprint

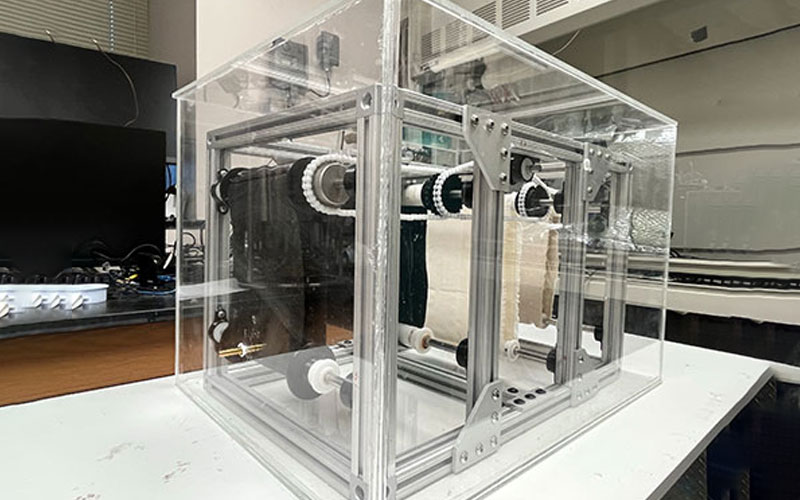

The technology proposed in this project, dry biofilm photobioreactor, is based on CCBP, which will be used as the platform for intensified microalgae cultivation from flue gas and fishery wastewater. Besides directly capturing carbon dioxide from flue gas and converting it into algae, the utilization of algae as aquafeed will boost greenhouse gas emission reduction.

“We believe that we can reduce harmful wastes from both pulp & paper and aquaculture industries and turn them into something useful. One key innovation of our solution is the dry biofilm. By making biofilm dry, the transport of carbon dioxide to the biocatalyst will be significantly enhanced, therefore improving carbon dioxide uptake and biomass productivity,” he said.

Researchers will move to a greenhouse-style 1,000-liter prototype, to be developed by DVO, for pilot testing at the Auburn University Fisheries. They will use dry microalgae biofilm as biocatalysts to intensify the flue gas conversion process and improve biomass productivity. Advanced and energy-efficient pulp & paper dewatering and drying techniques will be adapted for algae dewatering and drying.

Also Read: UFlex Announces USD 200 Million Capex for Egypt Facilities

Researchers will further implement systems engineering approaches that employ feedstock integration, logistic integration, process integration and energy/heat integration. The project is expected to require two years of intensive research and development activities, and effective communication and active participation among collaborators.