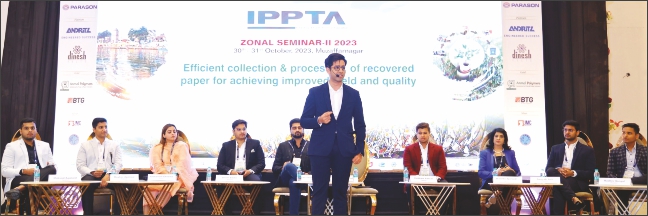

Indian Pulp & Paper Technical Association (IPPTA) conducted its Zonal Seminar – II in Muzaffarnagar on October 30 & 31. The 2-day event constitutes an information-charged inauguration session, highly interactive technical sessions and panel discussions.

Mr. S.V.R. Krishnan, Chief Operating Officer of Khanna Paper Mills Limited, delivered the keynote address for the inaugural session, “Almost 75-78% of paper production in India comes from the recovered fiber. The balance comes from the agro residue and wood-based fiber. Earlier wood based paper production, which used to be once at 35-40%, gradually reduced to 30%, and now is going as low as 12-15%. India is a net fiber importer. We are not fiber-rich, in that context, recovered fiber collection, processing, then improving the yield, and delivering the right quality for the customers – signifies paramount importance.

We had a very normal period before 2020. Post Covid, we got into a sudden new normal situation in 2021-22 where we had just lifted the industry. But soon the geopolitical scenario started changing due to the Ukraine and Russia war. Before things could come back on track, again one geopolitical scenario started with Israel and Gaza. Gone are those days when we used to have two-year budget sessions and five-year capex expansion. Today these things are diminishing and we are talking about quarterly planning. We don’t know what is in store for the next quarter with respect to the input raw material, the chemicals, the logistics, the mill operations, etc. It is not in the same format.

The machine running with a very stable gsm, and product mix before 2020, manufacturing 2/3/4 gsm changeover, is today doing close to 20 gsm changeover.” He further elaborated, “In the last five to ten years paper mills in the country have done phenomenal improvements & developments. But, it’s not enough. We should be proud that we are adding a lot of things for the green footprint. We have reduced the greenhouse gas emission footprint by 50-60%.

The energy consumption in the plant per ton of board/paper/kraft, we have traveled almost towards 35-40% improvement. Water consumption – we have improved, with almost 25-30% of the reduction in freshwater consumption. Then, what is the challenge – recovered fiber collection.”

Mr. Krishnan addressed the key topics for recovery and waste collection, “How to improve waste collection and spread the awareness on recycling? How to inculcate the habit of segregating at source right from the school level? Right from the complexes of the housing society or the gated communities. As long as we call it a waste, we don’t attach any importance to it. The moment we attach a value to it then the perception changes. We need to run campaigns & drives so that recovered fiber is collected & comes back to us. Mills can come forward and start working together, and have a centralized big collection system. What has happened in Sweden, Finland, Germany, – they were at 47% of recovery of the waste paper, today they have gone upto 80-85% of recovery – how? They have made phenomenal changes in terms of collection and segregation with big centralized plants having multiple lines of sorting, cutters, segregating conveyors, magnetic separators, manual operations, plastic removal systems etc.

Watch: JMC Paper Tech Launches New Subsidiary JMC Papers

Everything gets collected, bailed, and stacked at one corner in big areas. Then people go for spot checking and book the quantities. Why can’t it happen in India?” He emphasized the need for such an initiative, “It’s a question of who takes that initiative – it’s like five or six people, and we put that investment for our future. Then we will take the recovered fiber and distribute it based on your requirement and your capacity.”

Mr. Krishnan also reflected on fully harnessing the value of IT systems, “Are we staying contemporary or upgrading ourselves with the time? If we want first-class quality yield then we have to do systematic technological intervention. We are working on ERPs and a variety of IT systems – but how much do we leverage that? These systems can tell us so many things, ERP gives you so much insight – take out everything, do a meaningful analysis, and then come out with action plans. Only when you leverage all these things and efficiently process them that you get the desired results.”He further added, “All the things are metrics of measurements. What you can measure, you can monitor.

What you can monitor, then only it can be controlled. Every piece of equipment in the pulp and paper industry comes with INR 5-10 crore minimum. We should be careful and sensitized to move from perceived performance to actual performance. This is the improvement that is going to give you the yield and the quality improvement. Performance is defined as adequate output with inadequate resources.”

Mr. Pankaj Aggarwal, Managing Director of Bindlas Duplux Limited, delivered a speech on behalf of the Guest of Honour, Mr. Rakesh Kumar Bindal, Chairman of Bindals Papers Mills Limited. He began by introducing Mr. Bindal with a few insightful lines, emphasizing that, “A person in business is not successful solely through the accumulation of wealth. Money or the financial gains are temporary. A positive attitude of a person is what makes him successful. Success does not mean that he earns a lot of money. Success means that there should be a balance in life. He should do social service, he should stand in everyone’s happiness and sorrow.” Mr. Aggarwal commended Mr. Bindal for embodying these qualities and for his unwavering dedication to helping others. He concluded his speech by highlighting the recent inauguration of their sugar mill, a testament to Mr. Bindal’s visionary leadership.

Mr. Ganesh Bhadti, President of IPPTA and Director of Operations at Seshasayee Paper & Boards Limited, delivered the presidential address, “Nowadays we are all talking about sustainability, which is not a new subject, but the challenges, the methods, their magnitude, and their impact will be changing very fast. Now, in every industry, irrespective of its nature, size, or location, everybody is facing one or the other issues. Everybody is having an issue with the raw material, either with the availability or the price. Everyone is trying to improve their efficiency levels and get the maximum yield. Everybody is trying to improve their operating levels, and everybody wants to have manufacturing excellence in their processes. So lean, green, and clean practices are becoming a need. The way you want to do it, all depends on the size or the suitability for individual or individual organizations. Coming to the water, we are facing a situation in the months of summer where the treated water quality is much better than the intake water quality. Also for the mills situated in the Ganga basin, the challenges are entirely different. Energy front – everybody is having an issue with the availability and the price there too. The coal price is increasing every day.

Also Read: Paper Mart Emagazine Oct-Nov, 2023

Waste management is again becoming one of the major initiatives, zero waste is the future. Production cost, and quality – we cannot forget. One more dimension being added to the business nowadays is environment and social governance – one important subject, particularly the industries that are in the top 500 or 1000 rankings. With these challenges, the importance of recycled paper plays an important role and the efficiency levels in the mills are key points to finding a way for sustainability. What is needed today in recycled paper – is a strategic and very clear path for the collection, segregation, and proper mixing, and a design, and technology to use it. The quality issues, and strength properties, once we increase the number of recycling, will reduce. So replacement of waste paper with the virgin pulp at what ratio and at what time is also very important. For addressing all these challenges – what are the sustainable solutions? There is no tailor-made solution for any industry. So everyone has to make their choice. We have to have more collaborative work to find a solution for sustainability – maybe R&D activities like the zonal seminar in Mysore. Similarly, for the recycled paper – the kind of research that can be carried out, the alternate solution, and the strategic partnership for improving the efficiency levels in operations. The way we are operating now is mostly traditional. Something new has to come from innovations. Knowledge sharing is very important. As I said, there is no tailor-made solution – we have to pick what is suitable for us; this two-day seminar will help us.”

The Chief Guest, Mr. Rajeshwar Prasad Bansal, Chairman of Maruti Papers Limited, addressed the session, “In 1979, we started with 5 tons per day of paper at Shamli Paper Mill and Babri Paper Mill. We got excited the day we used to get 6 tons of paper. We were technologically quite weak that time and we had very high water & energy consumption per ton of paper produced. But now with time technology has improved a lot and the water & energy consumption has come down significantly. When we started the mill, the profit margin used to be better which has now narrowed down phenomenally. We used to buy waste paper for INR 1500 per ton and sell finished paper for INR 4500 per ton at that time. Paper industry in Muazaffarnagar district is facing a major challenge related to pollution norms after becoming part of the NCR region. Technologically we should try to reduce the cost of production. If there is such a development, then it should be discussed in such forums. I request you all to remain technologically sound & updated.”

The inaugural session ended with a Vote of Thanks from Mr. Pavan Khaitan, Vice President of IPPTA and Vice Chairman & Managing Director of Kuantum Papers Limited, “As we conclude this inaugural session, I cannot but reflect on two very important things – the amazing gathering that we have got for this seminar, and the crucial subject that has brought us together today. The valuable insights that we have gained – our collective focus should be on solving these vital issues, the ones that affect our environment and industry. During the seminar, we will be learning that through the adoption of smarter technologies, automation, and rigorous quality control measures, we can considerably improve the efficiency in our operations of processing the recovered paper and contributing to higher and better quality outputs.”