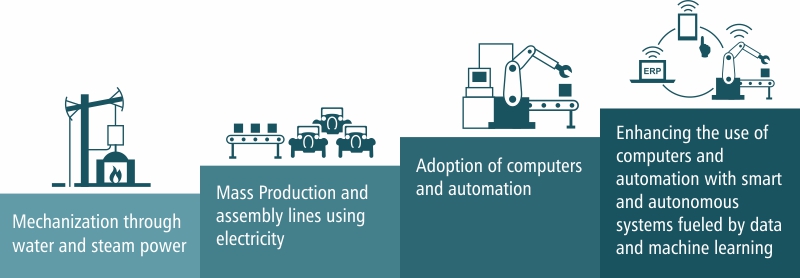

Digitalization is gradually transforming the way we produce products. Referred to as “Industry 4.0” in Europe, the “Industrial Internet of Things (IIoT)” in the United States, or just “smart manufacturing”, this transformation represents the fourth revolution that has occurred in manufacturing. The first industrial revolution was all about mechanization through water and steam power; the second industrial revolution was about mass production and assembly lines using electricity; the third industrial revolution was about the adoption of computers and automation; and the fourth industrial revolution is about enhancing the use of computers and automation with smart and autonomous systems fueled by data and machine learning. In other words, Industry 4.0 optimizes the computerization of Industry 3.0. It is surely not a marketing buzzword, for shifts are happening in manufacturing.

Introduction of computers in Industry 3.0 proved to be disruptive mainly because a completely new technology had been added to various processes. In Industry 4.0, computers are connecting and communicating with one another to make decisions without human involvement. Cyber-physical systems, the Internet of Things and the Internet of Systems are being combined to make Industry 4.0 possible and the smart factory a reality. Smart machines are getting smarter as they get access to more data; and with the support of these machines, factories will become more productive and efficient and less wasteful.

What’s Industry 4.0 all about?

The new digital industrial technology or Industry 4.0 enables manufacturers to gather and analyze data across machines, which inevitably entails more efficient, more flexible and faster processes for the production of higher quality goods at reduced costs. Technology experts say that this manufacturing revolution will not only increase productivity and change economics, but also foster industrial growth and modify workforce’s profile. They claim that these changes in manufacturing would ultimately change the competitiveness of companies and regions. Advanced digital technology is already in use in manufacturing; but combined with Industry 4.0, it will transform production in an unbelievable way. This combination will enhance efficiencies and make a big change in traditional production relationships among producers, suppliers and customers. It will also change the relationship between human and machine.

Building blocks of Industry 4.0

The vision of the industrial production of the future, Industry 4.0 is powered by nine technology advances. Many of these advances are already used in manufacturing; but with Industry 4.0, they will transform production – isolated optimized cells will come together as a fully integrated, automated and optimized production flow.

Let’s look at the nine technologies that are considered as the building blocks of Industry 4.0:

1. Big data and analytics

2. Automated robots

3. Simulation

4. Horizontal and vertical system integration

5. The Industrial Internet of Things

6. Cyber security

7. The cloud

8. Additive manufacturing

9. Augmented reality

Big Data and Analytics:

Big Data and Analytics:

In the manufacturing world, analytics based on large data has emerged only recently. It optimizes production quality, saves energy and improves equipment service. In the Industry 4.0 scenario, the collection and comprehensive evaluation of data from various sources will become standard to support real-time decision-making.

Automated Robots:

Automated Robots:

Robots are becoming more and more autonomous, cooperative and flexible, and it will not be long before they start interacting with one another and work safely with humans and learn from them. These automated robots will cost less and have a wider range of capabilities than those used in manufacturing today.

Simulation:

Simulation:

Robots are becoming more and more autonomous, cooperative and flexible, and it will not be long before they start interacting with one another and work safely with humans and learn from them. These automated robots will cost less and have a wider range of capabilities than those used in manufacturing today.

Horizontal and Vertical System Integration:

Horizontal and Vertical System Integration:

With Industry 4.0, companies, departments, functions and capabilities will become much more cohesive, as cross-company, universal data-integration networks evolve and enable automated value chains.

The Industrial Internet of Things:

The Industrial Internet of Things:

With the Industrial Internet of Things, many devices will be enriched with embedded computing and connected using standard technologies, thereby allowing field devices to communicate and interact both with one another and with more centralized controllers as required. In addition, it decentralizes analytics and decision-making, enabling real-time responses.

Cyber Security:

Cyber Security:

Because increased connectivity and use of standard communications come with Industry 4.0, the need to protect critical industrial systems and manufacturing lines from cyber-security threats will become stronger. Hence, secure, reliable communication and sophisticated identity and access management of machines and users will be essential.

The Cloud:

The Cloud:

With Industry 4.0, more production-related undertakings will need increased data sharing across sites and company boundaries. As a result, machine data and functionality will increasingly be deployed to the cloud. Even systems that monitor and control processes may become cloud-based.

Additive Manufacturing:

Additive Manufacturing:

This technology has improved by leaps and bounds in the last decade. With Industry 4.0, the existing additive-manufacturing methods will be widely used to produce small batches of customized products that offer construction advantages like complex, lightweight designs.

Augmented reality:

Augmented reality:

Augmented-reality-based systems support services like selecting parts in a warehouse, sending repair instructions over mobile devices, etc. In the future, companies will make greater use of augmented reality to provide workers with real-time information to improve decision-making and work procedures.

Digital Manufacturing

What has been the impact of digitalization on industrial production? McKinsey’s Digital Manufacturing Global Expert Survey 2018 reveals two interesting developments taking place in digital manufacturing: organizational commitment and clear progress and stagnation. The survey presents three key findings that characterized the industry’s development in 2018.

It was found that most manufacturing companies consider Digital Manufacturing a top priority and themselves ahead of the game. On average, 92 percent of respondents reported that they were either on the same level as or ahead of their peers when it came to Digital Manufacturing. The survey shows that a clear majority of manufacturing companies have already successfully piloted digital solutions. In each area of Digital Manufacturing – connectivity, intelligence and flexible automation – most of the respondent reported (at least) piloting solutions within their organizations. Across industry sectors and categories, Digital Manufacturing solutions are adopted consistently. In many cases, companies are piloting multiple digital solutions simultaneously. The global average is eight solutions, but the number varies widely by country. While Indian manufacturers report, on average, piloting more than 10 Digital Manufacturing technologies at any given time, companies in Japan are, on average, piloting only about four. Also, an analysis of implementation success over time reveals that significantly more companies are reporting successful piloting. Yet while success rates in implementing Digital Manufacturing solutions increases strongly in China, the USA and even Japan, piloting success among German companies has stagnated. Many companies have significant activity underway, but are not yet seeing meaningful bottom-line benefits from production.

The survey also found that for most companies, advancing beyond the pilot phase is still a big challenge. Even when companies report significant number of pilots, most cite significantly less progress in terms of broader rollout. So, while pilots are common, companywide rollout is still rare. In fact, the gap between the piloting and rollout is significantly larger than the gap between perceived relevance and piloting, suggesting that scaling is a bigger hurdle than getting the ball rolling.

An analysis by sector shows that the newer, more technologically advanced areas of the manufacturing sector (for example, industrial automation) are further ahead in the implementation of Digital Manufacturing than older, more established areas such as paper and packaging.

The results of the Digital Manufacturing Global Expert Survey 2018 clearly indicate that most companies are still struggling to move successfully from the piloting point solutions to delivering sustainable impact at scale. Success stories for capturing sustainable impact at scale are still few.

What Industry 4.0 can do for the paper industry?

Today’s paper industry seems quite ready to engage in the fourth industrial revolution. The pulp and paper industry is changing rapidly. Both consumer and market needs have evolved, and policy pressure and global competition have increased. So, to remain competitive, the industry has to innovate. Innovation can address not only processes, services and products, but also business models, workforce training and education. As a result, the industry sees great potential in digitalization.

Industry 4.0 and the Indian Paper Industry

In India, automation was not introduced until the early 1990s. It was initially introduced in some of the areas having sensors, Proportional Integral Derivative (PID) loops and stand-alone systems. Automation was first applied to quality control systems, then to process control and finally to the rest of the process. Currently, automation is not just limited to manufacturing processes; it is applied in data management of various operations and functions.

Many paper manufacturers in India are of the opinion that Industry 4.0 came rather late to the paper industry. They also believe that the industry is yet to take the whole ‘automation’ experience to a new level, which means going beyond the process. They claim that automation, digitization, data analytics, robotics, etc., have been instrumental in solving problems that have been difficult to overcome through manual interventions. Industry 4.0 and data management will help the industry control and bring down cost. Digitalization can prove to be beneficial especially in areas such as energy, efficiency, productivity, reliability, safety and quality. However, the need of the hour is to integrate all the functions within the industry. Indian industries, especially the paper industry, have miles to go in the area of automation. Indian manufacturing technology analysts say that although quite a few companies in India continue to be reluctant to invest in new technologies, Industry 4.0 cannot be overlooked, as digitalization can bring real benefits for the industry.

The Challenges

Economists Erik Brynjolfsson and Andrew McAfee claim that the fourth industrial revolution could disrupt labor markets. The net displacement of workers by machines might worsen the gap between returns to capital and returns to labor. They say that it is also possible that the displacement of workers by technology will result in a net increase in safe and rewarding jobs. They also say that in the future, talent, more than capital, will represent the critical factor of production. This will give rise to a job market increasingly segregated into “low-skill/low-pay” and “high-skill/high-pay” segments, which in turn, will lead to an increase in social tensions.

Indian manufacturing technology analysts believe that in order to face the challenges posed by Industry 4.0, companies in India need to upgrade the talent in their factories. They must invest in upskilling the staff and expanding their capabilities. They also need to invest in changing the existing work culture; and to keep workers relevant, it is necessary to upskill them in areas of analytics and digital technologies. Continual upskilling will prepare them for the changing environment and make them ready for future learning.

“For us, the Industrial Internet is evolution, not revolution,” says N. K. Jain, Director Sales (Asia Pacific) at Valmet India.

Paper Mart: Will Industry 4.0 bring considerable benefits to the pulp and paper industry, especially the pulp and paper industry in India?

N. K. Jain: Industry 4, Smart Factory and Industrial Digital Support are the names used by different suppliers enabling companies to connect their DCS system through VPN or other tools to their system and collect data on efficiency, productivity, consumption, down time, etc., for analysis and areas of improvement – something that the companies may not be able to properly analyze and deal with. This type of support definitely gives valuable feedback; and without much capital investment, they can increase productivity and reduce the operational cost.

PM: The process of automation and digitization has begun in the paper industry, but the industry is yet to take this whole experience to a new level, which means beyond the process. Do you agree with this observation? Please elaborate.

NKJ: Yes, I fully agree with this observation. As you already know, the Indian industry varies much in capacity with small machine with old technology, very less automation and control and even no Distributed Control System (DCS). It is difficult for companies to get information online or data for analysis. They depend on human skills and their knowledge of the process. But now equipment like Machine Drive Control System (MCS), Quality Control System (QCS) and DCS help them to get more information than that gathered through other ways. With new developments in areas like the Internet and computer technology, such as cloud storage, it is easy to store a huge amount of data and analyze it in a systematic way. This gives you information that can be used for correction and improvement.

PM: How receptive has the pulp and paper industry in India been to Industry 4.0? Do you think the demand for your new products and solutions is likely to increase in India?

NKJ: Actually, the real Industry 4.0 has neither been discussed nor implemented in the Indian industry. Consultancy firms like McKinsey and E&Y are telling the industry who can offer it data analysis and guaranteeing it some improvement in productivity, efficiency and consumption. Some big mills can afford it, but it is still much less than what the process designer and supplier can do. In my opinion, awareness is coming more and more from the competitive market.

PM: Is Industry 4.0 technology affordable enough for developing countries?

NKJ: Yes, it is not expensive if the customer has automation in place.

PM: Do you customize your products and solutions to the needs of your customers in India?

NKJ: Yes. For us, the Industrial Internet is evolution, not revolution. We constantly develop new digital solutions to take our customers’ performance forward by utilizing our unique combination of process technologies, automation and services. We have products like performance improvement, data analysis, remote support, scanning of the problem, etc.

PM: Are you currently developing more cutting-edge products and solutions for the pulp and paper industry? Please elaborate.

NKJ: Valmet currently has a strong infrastructure and technical expertise to serve its customers with the help of Industrial Internet. We have over 500 online connections with over 70,000 I/O tags monitored. We have been offering advanced remote analysis services to our customers for a long time.

PM: Don’t you think automation will increase joblessness, especially in developing economies?

NKJ: I don’t think automation will increase joblessness. It only helps to improve the performance of the mill and the individual. In the coming few years, more advanced automation technologies and more diagnostics will be embedded into the customer’s processes, keeping information security a high priority at the same time. Furthermore, mobile and remote services will be developed to the next level, ensuring the customer full mobile access to all information anytime and anywhere.

“As the IIoT will be a core topic in the future to maintain and enhance the ability to compete, Andritz has combined its innovative IIoT solutions, which are already field-proven in many reference plants, under the technology brand ‘Metris’, which covers all Andritz digital solutions,” says Sridhar Gopalan, Managing Director & CEO, Andritz Technologies Pvt. Ltd.

Paper Mart: Will Industry 4.0 bring considerable benefits to the pulp and paper industry, especially the pulp and paper industry in India?

Sridhar Gopalan: The terms Industrial Internet of Things (IIoT), industry 4.0. and Smart Factory are omnipresent nowadays, and not just in the industrial environment. Companies’ expectations of greater plant efficiency and increased profitability by networking machines and applying such technologies as Smart Sensors and Big Data Analytics have high priority. As the IIoT will be a core topic in the future to maintain and enhance the ability to compete, Andritz has combined its innovative IIoT solutions, which are already field-proven in many reference plants, under the technology brand “Metris”, which covers all Andritz digital solutions.

The economic benefits of using intelligent digital solutions in the pulp and paper industry are:

- Increased plant efficiency and profitability

- Optimized usage of resources

- Constant and high product quality

- Avoidance of production downtime and unplanned shutdowns

- Maximum user-friendliness; for example, easy control via smart phone or tablet PC

The operational benefits of using digital technology for India’s pulp producers include:

- Stable quality of production

- Better decisions by better informed operators

- Clearer information exchange between operating teams

- Maximization of equipment lifetime and optimization of maintenance schedules

- Minimization of downtime due to preventive maintenance

PM: The process of automation and digitization has begun in the paper industry, but the industry is yet to take this whole experience to a new level, which means beyond the process. Do you agree with this observation? Please elaborate.

SG: Yes, a lot of digitalization has already happened and has become part of modern plants; however, there is still much more that can be done. Current digitalization efforts tackle process efficiency and optimization by big data analyses, sensing plant conditions beyond the pure process and safety-related tasks, integration into ERP systems and linear robotics. In the future, the expectation is that systems, machines and humans will perform the required tasks in a cooperative manner with mutual guidance and smart interaction.

At Andritz we already have a very effective solution that combines our extensive knowledge of the industrial processes with the very latest in digital technology. Metris Optimization of Process Performance (OPP) is a service contract that has been proven to improve the performance of a variety of production systems. Metris OPP is a risk-free investment with guaranteed results. It is based on continuous developments in the three main Metris technologies – Smart Sensors, Big Data and Augmented Reality – and improves production systems by analysing a huge amount of data collected throughout the operation. Under the basic pricing model, charges are only incurred once concrete savings have been realised. Metris OPP has helped customers worldwide to save millions.

PM: How receptive has the pulp and paper industry in India been to Industry 4.0? Do you think the demand for your new products and solutions is likely to increase in India?

SG: Yes, we are expecting the demand of digital technology in general to increase, as it brings performance and process efficiency improvements to any production facility, independently of their location. With Metris digital solutions, Andritz has been developing a very special ecosystem offering a plurality of tailored solutions to the pulp and paper industry. Metris OPP is field-proven in various industry applications word-wide and enjoys a high reputation and customer satisfaction.

PM: Is Industry 4.0 technology affordable enough for developing countries?

SG: I would turn around the question – can developing countries afford to not invest in Industry 4.0 and digital technology? Most often investments in digitalization pay back quickly due to the improved process and plant performance. India has got a highly skilled and well-educated workforce with some of the best IT engineers in the world – thus industry 4.0 may constitute an opportunity to employ those high potentials in the domestic ecosystem and avoid having them leave the country.

We are on the cusp of the Fourth Industrial Revolution, where automation of manufacturing processes is upgraded with smart autonomous systems capable of self-cognition, self-optimization and self-customization. Industry 4.0 is affecting all sectors and disciplines. It will also have a huge impact on developing countries, due to new economic forces in the global market.

PM: Do you customize your products and solutions to the needs of your customers in India?

SG: All our Metris products are tailored specially according to our customers’ needs, independently of their location. With or flexible Metris OPP platform, we can develop together with our customers the right digitalization concept according to the demands and possibilities on site.

PM: Are you currently developing more cutting-edge products and solutions for the pulp and paper industry? Please elaborate.

SG: At Andritz we are constantly working on more integrated and interoperable solutions and services that aim to maximize the benefit of customers throughout the lifetime of all pulp and paper equipment.

PM: Don’t you think automation will increase joblessness, especially in developing economies?

SG: I think the jobs will shift, but humans will remain in the loop for the foreseeable future. Automated tasks will become more tailored to typical human skills, for example, flexibility and creativity, whereas machines will take over more and more dangerous tasks. Nonetheless, different levels of skills will be required from maintenance to engineering which will not fully be replaced by automation robots.

“Exactly for the same reasons and experience as in the cases of communication and the Internet revolution, no industry can afford to stay away from being on the Industry 4.0 bandwagon,” says Madhav Vemuri, President-Industrial Automations and Country Service Operations, ABB India Limited.

“Exactly for the same reasons and experience as in the cases of communication and the Internet revolution, no industry can afford to stay away from being on the Industry 4.0 bandwagon,” says Madhav Vemuri, President-Industrial Automations and Country Service Operations, ABB India Limited.

Paper Mart: Will Industry 4.0 bring considerable benefits to the pulp and paper industry, especially the pulp and paper industry in India?

Madhav Vemuri: Definitely. Automation and sensorization are all about data, and data drives transparency leading to fact-based decision-making in real time. Most of the applications for existing control systems, Level 2 supervisory systems and MES systems focus on process control and optimization. However, the most important aspects of the data and analytics-driven insights are how they become an extension of existing control loops to deliver significant incremental value in operational efficiency, asset integrity, quality, safety and business excellence for the Indian pulp and paper industry. With fierce competition and shrinking margins, production at any cost is definitely not the desired approach for the industry. So, sweating the production assets in a constructive way will remain the order of the day, which means that leveraging the benefits of Industry 4.0 will allow papermakers to have deep and objective insights into asset condition/status early in time. This in turn will drive key decisions for inventory, production scheduling, OPEX, investments, debottlenecking initiatives, etc.

ABB Ability™ is our unified, cross-industry digital offering — extending from device to edge to cloud — with devices, systems, solutions, services and a platform, all enabling our customers to know more, do more and do better, together. ABB Ability™ connects our customers to the power of the Industrial Internet of Things and, through our services and expertise, goes further by turning data insights into direct action that “closes the loop” and generates customer value in the physical world.

PM: The process of automation and digitization has begun in the paper industry, but the industry is yet to take this whole experience to a new level, which means beyond the process. Do you agree with this observation? Please elaborate.

MV: First, let’s acknowledge the great vision and progressive leadership demonstrated by the Indian pulp and paper (P&P) sector in embracing the new technologies and techniques, particularly from the equipment standpoint, to remain energy-efficient and environmentally compliant. However, isolated efforts embracing Industry 4.0 shouldn’t be misread as a reflection of the general awareness and acceptance, let alone the maturity of the Indian P&P sector at large. Only a part of the delivered functionality and features of the installed control systems are really used. Alarm management, loop performance management, integrated asset view, etc., are simple examples of the potential that could be unleashed with very minimal efforts and strong management commitment. The operational technology and information technology (OT-IT) integration is another area which remains majorly unexploited, except for Enterprise Resource Planning (ERP) interface and a few key performance indicator (KPI) dashboards and reports. Breaking the current paradigms, Industry 4.0 will drive a holistic and integrated value chain approach vis-à-vis the current islands of standalone systems and disconnected, if not contradicting, objectives.

PM: How receptive has the pulp and paper industry in India been to Industry 4.0? Do you think the demand for your new products and solutions is likely to increase in India?

MV: Exactly for the same reasons and experience as in the cases of communication and the Internet revolution, no industry can afford to stay away from being on the Industry 4.0 bandwagon. So, there will definitely be an adaption of the next level solutions and technologies to be Industry 4.0-compliant, of course with different degrees of scope and scale. I strongly believe that this Industry 4.0 transformation will have a significant pull for new gen products, sensors, systems and solutions. We are well positioned to seamlessly deploy more custom-configured, impactful and affordable solutions across the huge brownfield installed base, while the standard new generation Industry 4.0-enabled solutions will be right by default, from the procurement and design phase for greenfield projects.

PM: Is Industry 4.0 technology affordable enough for developing countries?

MV: Sure, they will remain affordable even in developing countries like India, provided we take a holistic view of the investments by moving away from price-focus to sustained value generation. While some Industry 4.0 initiatives and components are self-funding with very attractive ROI projections, others value drivers like resource productivity and overall reliability may not necessarily get translated into ROI estimates. Hence, it’s extremely critical to take a pragmatic and progressive approach to having a blend of such quick ROI projects and few ecosystem build-up actions for an optimal cash-flow scenario to be prepared for the high ROI opportunities that the future holds.

PM: Do you customize your products and solutions to the needs of your customers in India?

MV: ABB’s global experience from diversified sectors and applications is the key to developing and deploying the time-tested and robust Industry 4.0 solution portfolio. With a unique blend of huge process domain know-how and equipment knowledge, ABB’s process and equipment models and analytical solutions are proven and standard. However, every single customer installation has something unique and calls for some amount of customization. The trick here should be not to reinvent the solution, which will let go an opportunity of leveraging the synergies of the scale and skills, but to leverage deep industry experience to apply configurability to meet varying customer needs.

PM: Are you currently developing more cutting-edge products and solutions for the pulp and paper industry? Please elaborate.

MV: It’s a continuous process at ABB. We invest around 1.5 billion USD per year on R&D activities. For example, we are focused on leveraging solutions like digital twins and augmented reality to bring a new level of visualization and problem-solving to mills. All that ties to our focus on helping papermakers create the modern, digital mill which is laser focused on leveraging process intelligence for rapid issue resolution and improved productivity. As a company, ABB Ability will remain the flagship solution suit, helping our industry customers to accomplish digital transformation seamlessly and elegantly.

PM: Don’t you think automation will increase joblessness, especially in developing economies?

MV: Introduction of robots in the German automobile industry in the mid-twentieth century created similar doubts and concerns, but we are a witness to what happened ultimately. Similarly, Internet banking is another example: People thought that digitalization and e-commerce would take away jobs across the banking sector, but Internet banking gave rise to other manifestations of employment. So, we should not be afraid of technological advancements, as they not only enhance the quality of life in general, but also improve the employment conditions for our workforce.

Industry 4.0 will surely change the nature of jobs and tasks that people currently do, but that doesn’t mean that the number of jobs will be reduced. Indeed, job profiles and working practices will change, leading to a safer and healthier working environment. To that extent, Industry 4.0 brings in an urgent and profound need for the reskilling/upskilling of our workforce to better leverage digital capabilities and transform how routine or labor-intensive actions are performed.

“Industry 4.0 is sometimes seen as a cost. But if you view it from a long-term perspective, something that an entrepreneur should do, you will instantly know that it is a saving,” says Simon Lorenzetti, Area Salesman, A.Celli Group.

PM: Will Industry 4.0 bring considerable benefits to the pulp and paper industry, especially the pulp and paper industry in India?

Simon Lorenzetti: Yes, I am sure that Industry 4.0 will push the growth of the Indian pulp and paper industry. I think that this innovation can give the opportunity to India to jump from its current technology position to the number-one position. The market is constantly looking for systems that require less human intervention, that are capable of programming maintenance activities and that can be consistently monitored by all stakeholders. That’s why A.Celli Group offers software and hardware solutions to optimize production and maintenance processes with a view to Industry 4.0, developing advanced DCS controls, innovative industrial automation applications and integrated packaging systems, primarily involved in the market of machine manufacturers for the world of tissue and nonwovens.

Our goal is to optimize production and maintenance processes with a view to Industry 4.0:

- Find out which production is highly critical (wound meter, small diameter and slippery product).

- Verify how much we can run with a specific production without creating a bottleneck.

- Predict the extra time of the rewinder (compared with the line). By mixing this information with the stock station’s capacity, we can know how long we can resist a specific production.

We can now efficiently smart plan the production to adapt it to a specific plant and to avoid a bottleneck. This will be done in a smart way. We are not making it according to the production planner skills and experience but according to data consistency. The system during the production will help the operator to make smart choices such as cleaning time and optimization of the full production sequence. Machines can now be pushed as much as needed for a specific production and not always at the maximum in order to preserve them. Machine performance can be set as required.

PM: The process of automation and digitization has begun in the paper industry, but the industry is yet to take this whole experience to a new level, which means beyond the process. Do you agree with this observation? Please elaborate.

SL: Yes, we endorse this observation. The process is the first step towards automation. Consider an example. All the good things done during the production can be destroyed by applying the wrong label or by losing it. The label is really important as it is the finished reel ID carrying all the information related to the product. Label mismatching or even worst lost/not applied can result in a big reject by the final customer.

In order to verify the correct application of the label and its data consistency, we have the Label Verification system which is used to verify data consistency by checking the real data on the label, comparing it with the one supposed to be printed, which comes directly from the plant’s Enterprise Resource Planning (ERP). The system can make sure that the bundle is correctly labeled by adding tools to check label presence and data consistency to get rid of human errors.

PM: How receptive has the pulp and paper industry in India been to Industry 4.0? Do you think the demand for your new products and solutions is likely to increase in India?

SL: The pulp and paper industry in India is growing day by day. I think that in a few years, if the trend will remain constant, India will become one of the first countries in terms of technology innovation and development. Many researchers are saying that India has all the potential to be the “new China” in terms of development capacity. We are ready to catch the booming of the Indian economy for the next 20 years.

PM: Is Industry 4.0 technology affordable enough for developing countries?

SL: Industry 4.0 is sometimes seen as a cost. But if you view it from a long-term perspective, something that an entrepreneur should do, you will instantly know that it is a saving. You see, the initial cost of automation is not huge and from the first day of operation you start saving money.

Here are some of the benefits that Industry 4.0 can bring for the pulp and paper industry:

- Energy saving due to automatic controls of power.

- Saving on raw materials (pulp, water and chemicals) due to optimization of machine input.

- Few or no production interruptions due to brakes.

- Optimized maintenance process.

- Improved final-product quality.

- No mistakes with labeling and the shipment process.

PM: Do you customize your products and solutions to the needs of your customers in India?

SL: We always work for our customers. This is why we let them guide us on what they are looking for in the project. There are many different possible solutions, so a fair collaboration from the beginning is a must for us. We are a medium-sized company, and that enables us to be flexible. We usually involve our customers in the process of choosing the best solution for them.

PM: Are you currently developing more cutting-edge products and solutions for the pulp and paper industry? Please elaborate.

SL: A.Celli Group is constantly investing in R & D especially on automation. By adding new control tools on the machine, such as sensors and specific instrumentation, we can control the overall machine conditions with our condition monitoring and then we can even check the energy consumption (energy monitoring). Moreover, just a few months ago, A.Celli developed, in partnership with Tecnoferrari, R-WAY AGV, which is extremely easy to install and maintain. It was designed to simplify the flows and processes of production sites where there is a strong emphasis on complete automation. R-WAY AGV is an automatic guided movement vehicle that enables continuous production and can guarantee absolute safety for the operators and the structure. It is flexible, fast and smart. In keeping with Industry 4.0, it interacts and communicates with data analysis and tracking systems and meets the specific and individual needs of the manufacturer. In addition, A.Celli has a new “sister” company called Extreme Automation which focuses mainly on Industry 4.0. The final aim is to improve quality and efficiency of the whole production chain, thereby reducing costs for the customer.

PM: Don’t you think automation will increase joblessness, especially in developing economies?

SL: I think that this view is not correct. The ‘Automation 4.0 disruption’ has already created thousands of new jobs related to the IT world. And this is definitely true for India which is a hub for IT engineers. According to a research analysis carried out by McKinsey Global Institute, automation will never substitute human work but it will help to increase human safety and the productivity of the industry. This will push up economic growth, thereby creating new jobs and increasing human well-being.