Khanna Paper Mills has successfully reduced its fresh water consumption by approximately 12–13% over the past few years, currently using 12 m³ per ton of water across its entire factory operations. The company is actively pursuing Minimum Liquid Discharge (MLD) strategies, along with advanced filtration technologies and ion exchange mechanisms, to further enhance water efficiency. In an exclusive interview with Paper Mart, Mr. S.V.R. Krishnan, Executive Director – Operations at Khanna Paper Mills, shared insights into the company’s forward-looking plans to implement Reverse Osmosis (RO) plants equipped with polishing filters, aiming to achieve an additional 15% reduction in fresh water usage.

Paper Mart: How has your understanding or approach to water circularity evolved over time? How close are you to achieving it?

S.V.R. Krishnan: Water circularity in a paper mill is more about reducing the fresh water intake by reusing more of the process or backwater streams after suitable treatment. This approach has been very well understood and implemented over the past two decades by most of the mills.

In Khanna Paper Mills, as the factory is situated on the highway and within the city limits, it is more like a mandate to keep the fresh water intake below a certain norm on a daily / consistent basis, to keep the factory running smoothly.

We have reduced the fresh water withdrawal in the last couple of years by 12-13%. Though there were many challenges while doing so, we are taking it as an opportunity for improving the overall efficiency of the plant operations.

Watch: In Pursuit of Lesser Water Footprint

PM: To what extent have you implemented internal water reuse, recovery, or circular systems (including ZLD, water loop closure, or rainwater harvesting)?

SK: At Khanna Paper Mills, we strictly follow the ‘4R’ principle- Reduce, Reuse, Recycle and Recover, for water management.

We have a dedicated team of people under EMC (Environment Management Cell), who focus on the area wise fresh water consumption on a shift-to-shift basis and the actions are taken by the respective sections / departments.

Our water closure is to an extent of 75%, and when attempted beyond this, there are operational and quality issues like poor runnability / more breaks and inferior performance of the specialty chemicals and process chemicals, used at the wet-end of the paper and paperboard machines respectively.

So, we strongly feel that the ZLD concept is practically very difficult and associated with a huge CapEx and OpEx, which many of the mills cannot afford. Hence, we are working on the MLD (Minimum Liquid Discharge), meeting all the liquid pollution norms, for the water let-out.

PM: Which technologies or solutions have you found most effective in reducing your freshwater consumption or increasing internal recycling?

SK: We can recycle more water back into the system, with the suitable treatment of the process water / influences from various process areas like fiber processing plants, chemical preparation plants, coating colour kitchen and paper and board machines etc.

Though there are various treatment methods like clarification, filtration (ultra and nano filtration with membranes), chemical treatment / flocculation, ion exchanging process with the poly electrolytes and reverse osmosis etc, we get better results with the combination of chemical treatment followed by mechanical filtering.

We are also working with various filtering mediums and ion exchange mechanisms. We are also planning for the RO plant with the polishing filters, for reducing the fresh water consumption by another 15% from the current levels.

We need to find the techno- economic solution for the ZLD concept, provide some workable financial package, attractive incentives for the mills coming out with sustainable models of MLD and ZLD and then insist on ZLD for the new pulp and paper mill projects.

PM: What are the biggest roadblocks (technical, financial, or regulatory) in achieving higher levels of water reuse or moving toward ZLD?

SK: Technically, the water closure beyond 80-85% results in the buildup of COD and TDS levels, which will reduce the efficiency of the process chemicals and finally impacting the machine performance ( with more web breaks and more rejection of the final products), along with the foul smell/ odour on the final product.

If ZLD, in the true sense, has to be adopted in a paper mill, we need to have an elaborate ETP. Starting from the basic primary clarifier with the chemical treatment, aeration chambers with MBBR, followed by secondary and tertiary clarifier, filters with special medium, sand filters and finally RO plant / units with the crystallisation of the salts and dryers. This entire set up for a 10-15 MLD treatment plant would approximately cost INR 80-100 crore and hence the CapEx cost is prohibitive for taking such a bold step on ZLD, in the given global , paper and paperboard market and industry scenario.

We have been discussing in various forums of IPPTA, IPMA and CII that the government has to take a pragmatic approach rather than just insisting on ZLD, which is not practically feasible for every paper mill to comply with. We need to first find the techno- economic solution for the ZLD concept, provide some workable financial package, attractive incentives for the mills coming out with sustainable models of MLD and ZLD and then insist on ZLD for the new pulp and paper mill projects.

PM: How do local or national regulations affect your water management goals? Have sustainability mandates accelerated your water-saving initiatives?

SK: Whether any regulation or not, it is a question of survival for the paper mills and they will have to continually work on reducing water footprint, if the business is to be made sustainable.

The rivers are getting dried, water bodies are shrinking and the ground water table is depleting. The states like Punjab, where the water was abundant, is now talking about stringent control measures for conserving the surface water and ground water. The sustainability mandates have really accelerated our water saving initiatives. All our new projects are being taken up by keeping the water and energy consumption in focus.

PM: Have your investments in water reuse or ZLD technologies paid off in terms of savings, efficiency, or compliance?

SK: Our water reuse and conservation measures have significantly helped us comply with pollution control norms, improved efficiency across several continuous operational areas, and led to considerable cost savings—ranging from the withdrawal of fresh water to the pumping of influents to the ETP plant.

PM: Do you involve technology providers in planning or customizing your water treatment systems? Any successful collaborations worth sharing?

SK: We involve the experts in the water treatment and water management areas before undertaking any modification. Currently, we are in the process of augmenting our ETP operation with respect to handling more volume, before we undertake the next expansion project on one of our high speed paper machines.

We are working on the MLD (Minimum Liquid Discharge), meeting all the liquid pollution norms, for the water let-out.

PM: How do you see your water use evolving in the next 5–10 years? What would “full circularity” look like in your operations? What kinds of support in terms of technology, partnerships, or policies would help you get there?

SK: We are looking at reducing the fresh water intake by another 15% from the current level. I really doubt whether we will be in a position to achieve ‘full circularity’ in our operation. The techno-economical proposal with the financial support from the government with attractive incentives may pull more mills to put their efforts on water circularity.

PM: Have you considered or implemented digital twins to simulate, monitor, or optimize your water use? What kind of improvements could such systems bring to your operations?

SK: We have not implemented any virtual control system for real-time monitoring and controlling the fresh water consumption. But we have standard dashboards in each department for the consumption of fresh water and the extent of reuse of the process backwater. We have undertaken some projects on the digital twins under Industry 4.0 in other areas like CAP (Chemical Additive Preparation), starch preparation and dosing system, and in CCK.

Also Read: Pakka Aims to Reduce Water Consumption to 22 m³/ton by 2030

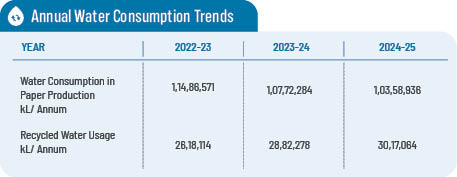

PM: What is your current annual water consumption, and how has the consumption reduced over the past few years? Kindly support the answer with the table below.

SK: We are currently consuming 12 m³ per ton for the whole factory operation, and on the machine the specific water consumption is 5-6 m³ per ton on a consistent basis.

Over the past couple of years, we have reduced fresh water consumption by approximately 12–13% through various departmental initiatives. This includes optimizing water at usage points by increasing grams per liter (GPL) of solids, enhancing consistencies wherever possible, and actively promoting the usage of treated effluent water in almost all non-critical operational areas.

It is also possible by implementing modular control systems in high water consumption areas, conducting monthly campaigns to address leakages, pilferage, and overflows, and fostering effective communication by actively involving all team members in the process.