Austria-headquartered ANDRITZ will provide two tissue machines equipped with a large suction press and a PrimeDry Steel Yankee, along with a stock preparation equipment, to its mill in Zhangzhou, Fujian Province, China.

December 06, 2021

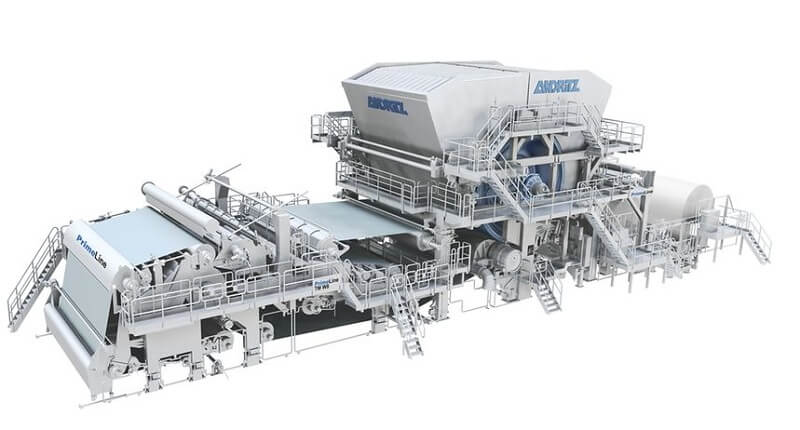

Zhangzhou, Fujian-based mill Liansheng Paper Industry Co. Ltd, has ordered two CrescentFormer tissue machines of type PrimeLineTM W 2000 with a design speed of 2,000 m/min and a working width of 5.65 m from ANDRITZ. The machines are equipped with a large suction press and a PrimeDry Steel Yankee with a diameter of 20 ft.

The PrimeDry Hood ST – steam-heated Yankee hood – is engineered with a steam-heated air system. It operates in a temperature range of around 200°C, which can provide an additional 15-25% drying capacity compared to the Yankee alone. The tissue machine, including all key components, will be manufactured at the ANDRITZ workshop in Foshan, China, while the hoods will be supplied by ANDRITZ Novimpianti, Italy.

Watch: Paper Mart News Roundup

Further, ANDRITZ will also provide – tailored automation systems, including PrimeControl MCS (Machine Control System), QCS (Quality Control System), pneumatic and hydraulic equipment, and lubrication systems.

Also Read: Suzano, Brazil Orders a Pulp Production Line from ANDRITZ

The stock preparation systems, using NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp) as raw material, will feature highly efficient ANDRITZ equipment such as FibreSolve FSV pulpers. As a technological highlight, special refining systems will be applied, consisting of a pulp screw press and an HC refiner, type CDIPL, operating for LBKP at a high consistency of 25-30 percent.

The innovative refining set-up will enable superior fiber properties with stable runnability. The scope of supply also includes approach flow systems and broke handling. ANDRITZ has supplied over 10 stock preparation systems to Liansheng Paper since 2009.