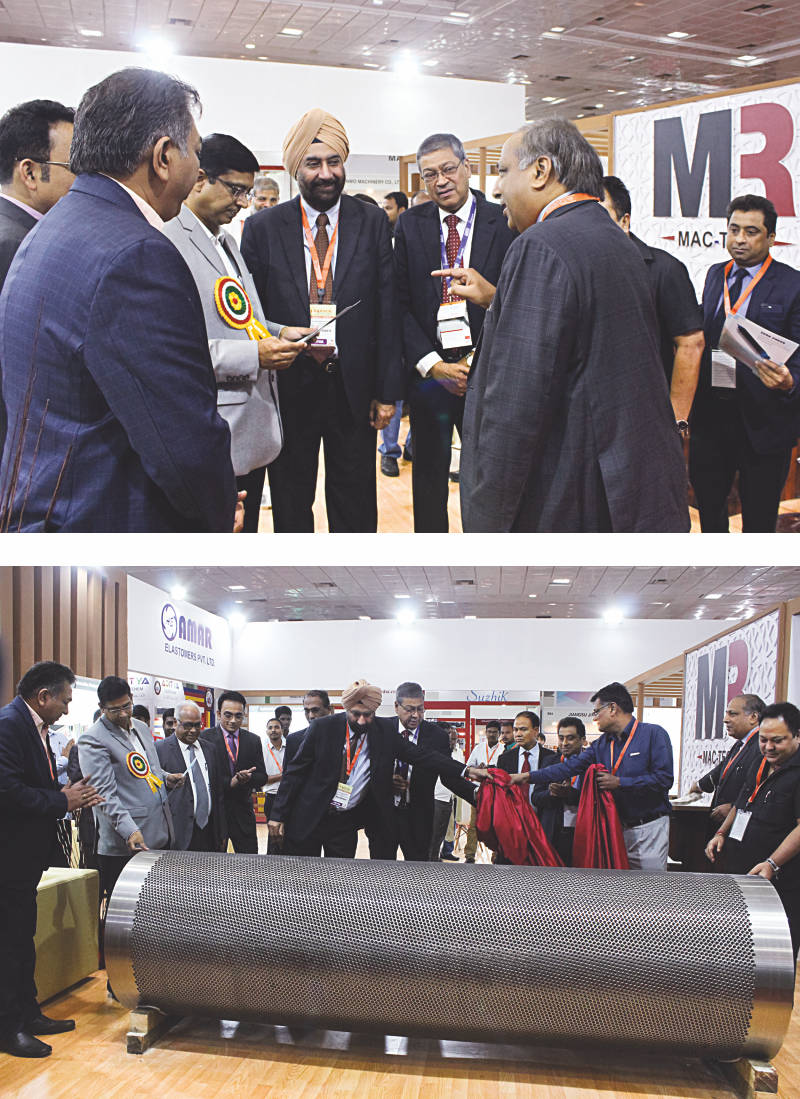

Paperex South India 2018, 5th International Exhibition & Conference on Pulp &Paper and Allied Industries, was organized at Chennai Trade Centre from November 15-17 in Chennai.

The exhibition was conjoined by a parallel conference by IARPMA running whole three days including various panel discussions and technical sessions raising pertinent issue of the paper industry, especially packaging and recycling. The event was organized by International Trade and Exhibitions Pvt Ltd (ITEI) in association with Indian Agro & Recycled Paper Mill Association (IARPMA). The inaugural session welcomed Mr. N. Gokulkrishnan, Hon’ble Member of Parliament as the chief guest and Dr. B.P. Thapliyal, Director, CPPRI, Sharanpur delivered the keynote address. The guest of honor Mr. S. Sivashanmugaraja, IAS, MD, TNPL also addressed at the inaugural session beside Mr. Anil Kumar, Executive Director and CEO of Shreyans Industries Ltd. and Mr. Parmod Agarwal, President, IARPMA and CMD of Rama Paper Mills Ltd. highlighting some of the persistent challenges the industry is facing and how to overcome them.

The exhibition was conjoined by a parallel conference by IARPMA running whole three days including various panel discussions and technical sessions raising pertinent issue of the paper industry, especially packaging and recycling. The event was organized by International Trade and Exhibitions Pvt Ltd (ITEI) in association with Indian Agro & Recycled Paper Mill Association (IARPMA). The inaugural session welcomed Mr. N. Gokulkrishnan, Hon’ble Member of Parliament as the chief guest and Dr. B.P. Thapliyal, Director, CPPRI, Sharanpur delivered the keynote address. The guest of honor Mr. S. Sivashanmugaraja, IAS, MD, TNPL also addressed at the inaugural session beside Mr. Anil Kumar, Executive Director and CEO of Shreyans Industries Ltd. and Mr. Parmod Agarwal, President, IARPMA and CMD of Rama Paper Mills Ltd. highlighting some of the persistent challenges the industry is facing and how to overcome them.

Right Industry Statistics: Emphasis on Diligent Data Collection

The statistics revealing the figures for installed capacity and actual production in the Indian paper industry has been questioned on more than one occasions in the past. Raising the same doubt over these figures again Mr. Anil Kumar, Executive Director and CEO of Shreyans Industries Ltd. said, “The data from various sources about production figures vary vastly and do not give clear cut picture in order to prepare ourselves as per actual on-ground scenario. All the statistics including data from CPPRI, IPPTA talk about 17-19 million tonnes but general consensus is that we are not less than 25 million tonnes in actual production as far as India is concerned. If that’s the actual case, it alters everything. Not only our planning based on 18-19 million tonnes production figure is wrong but also the estimate of per capita consumption being just 14 kg is erroneous. For a 25 million tonnes production, per capita consumption must be hovering somewhere around 18 kg. ”

Mr. Kumar further stressed the need of credible data collection from the industry giving right picture. “The first step is to cautiously find out at least what we are producing today. This step can be taken by committees like CPPRI, IPPTA, state level associations and even the various paper mills can help in contributing to the exact data on the production. Once the figures are collected, there should be a way forward to evaluate the exact production and consumption. Working on wrong figures doesn’t help the industry. Instead of repeating in every conference the same figures, which is far from the exact figures to say the least, little rework can be done to present the correct figures.”

He said, “I think that issues are very clear before the industry, and whatever figure we agree to, hardly 15 percent are from agro based paper mills, around 28 percent are from wood based mills and bulk of the production is coming from recycled paper based mills which is 56-58 percent today. Also, most of the new capacities and expansions are coming from recycled mills sector.”

Speaking on raw material security, Mr. Kumar said, “We often face issues with the availability of raw material and fiber. In fact, as far as availability of fiber is concerned, all the three sectors — be it wood based, agro, or recycled mills — we have to come out with a specific policy regarding making wastelands and forest areas available to the paper industry for plantations to source its own raw material. Regardless of the efforts put in by the industry in areas of social and farm forestry, the availability of raw material still remains an unresolved issue. While the requirement of wood and fiber is being met, the cost is really exorbitant as compared to what International industry pays for a tonne of wood. A serious note of this should be taken into consideration that what can be done. On one end, we have a large degraded forest land which is going from bad to worse year on year; and on the other, the authorities are doing nothing to make those forest areas available to the paper industry.

“For agro-based mills, the competing usage of bagasse for cogeneration in sugar mills and rice straws are not coming as per mills’ requirements as an alternate source of fiber. The fiber sources remain again a very big issue as far as agro-based mills are concerned.

“Talking about the recycled mills with 56-58 percent of total production, the collection system still remains below par. In countries like Japan, the collection rates has gone up significantly to 70 percent against a meager 20-23 percent in our country. Some efforts are being taken by CPPRI and Development Council for Pulp Paper & Allied Industries to undertake pilot projects in certain cities where some kind of framework could be put in place to make more recycled fibers available to the industry.”

“Talking about the recycled mills with 56-58 percent of total production, the collection system still remains below par. In countries like Japan, the collection rates has gone up significantly to 70 percent against a meager 20-23 percent in our country. Some efforts are being taken by CPPRI and Development Council for Pulp Paper & Allied Industries to undertake pilot projects in certain cities where some kind of framework could be put in place to make more recycled fibers available to the industry.”

Mr. Kumar further said, “One very good thing about the paper industry in India is that the demand growth is still intact. In packaging sector, we are almost growing at double digit figures year-on-year, estimated at more than ten percent. As far as W&P paper is concerned, the growth driver is of course the education sector. For a developing nation like India, the education in the foreseeable future would be through paper route only. Education through e-learning and digital methods will take some time to emerge in India. Tissue is also one of the fastest growing sectors though the percentage of 15-20 percent means nothing and could be deceptive as far as absolute tonnage is concerned. However, the demand of tissue paper is fast coming up and the industry is now concentrating on installing more capacities in tissue segment. Surprisingly, when newsprint is dying the world over, we still have a positive growth in the country as far as newsprint consumption is concerned. All the four sectors — packaging, writing & printing, newsprint, and tissue — have high demand growth, which is a positive sign for the paper industry.”

India Needs Higher Waste Recovery

Speaking mainly on the status of Indian recycled fibre based paper industries, Mr. Parmod Agarwal, President, IARPMA and CMD of Rama Paper Mills Ltd. said, “According to Central Pulp & Paper Research Institute (CPPRI), around 57-58 percent of paper is currently coming from recycled fiber segment which is steadily growing. We would like to maintain the growth of the segment by sticking to environmental fundamentals. The main drivers for the growth recycled fiber based paper production are least energy, water, and chemical consumptions.”

Mr. Agarwal raised the concern of low waste paper recovery rate in India and said, “The segment needs an increased recovery rate. The collection of waste paper in India is very poor compared to the rest of the world, especially countries like Japan. Our recovery rate is only 17-30 percent against the world’s average of 60-70 percent. We still have to go a long way in increasing the recovery rate. A number of committees studying the subject have suggested various steps to be taken by the government as well as the society to reduce the import of waste paper.

Mr. Agarwal raised the concern of low waste paper recovery rate in India and said, “The segment needs an increased recovery rate. The collection of waste paper in India is very poor compared to the rest of the world, especially countries like Japan. Our recovery rate is only 17-30 percent against the world’s average of 60-70 percent. We still have to go a long way in increasing the recovery rate. A number of committees studying the subject have suggested various steps to be taken by the government as well as the society to reduce the import of waste paper.

“Today we are importing around 10-12 million tonnes of waste paper and only 3-4 million tonnes are recovered domestically, out of 18 million tonnes consumption. There is a great scope of improvement there. There is a need to create awareness amongst the households to segregate the waste paper and avoid mixing other material with it. Similarly, the use of the waste paper other than recycling for papermaking should be discouraged through appropriate policies formed by the government. The government along with the society may undertake campaigns for increasing the recovery rate.”

Industry 4.0: Towards Value-Chain Integration

Central Pulp and Paper Research Institute

Presenting the keynote address on technology innovations and their absorption in Indian pulp, paper and packaging industry, Mr. B.P. Thapliyal, Director, Central Pulp and Paper Research Institute started with a brief scenario of the paper industry globally and its changing dynamics. He said, “We look into the global scenario, the paper and forest products industry as a whole is growing but at a slower pace, of almost one percent. The global industry analysis reveals that the structure of the industry is changing very significantly. Over the years, the graphic paper market and the demand worldwide is facing decline but this decline is balanced by the increasing demand for packaging and tissue products. In all, the demand for fiber based products is set to increase globally with some segments growing faster than others.

“A study by Zion Market Research from US shows that the global paper packaging materials market stood at almost USD 300 billion in 2015. Witnessing an incredible rise over the period from 2015-21, the revenue in this market is projected to touch USD 362.65 billion by 2021. India is experiencing the growth in packaging sector coupled with growth in industrialization and consumerism in society. The Indian packaging sector is among the highest growth industry and it is growing at rate of 15-20 percent per annum. Currently, it is the fifth largest sector in the Indian economy. The value of packaging consumption in India amounted to INR 1488 billion in 2018.”

“A study by Zion Market Research from US shows that the global paper packaging materials market stood at almost USD 300 billion in 2015. Witnessing an incredible rise over the period from 2015-21, the revenue in this market is projected to touch USD 362.65 billion by 2021. India is experiencing the growth in packaging sector coupled with growth in industrialization and consumerism in society. The Indian packaging sector is among the highest growth industry and it is growing at rate of 15-20 percent per annum. Currently, it is the fifth largest sector in the Indian economy. The value of packaging consumption in India amounted to INR 1488 billion in 2018.”

Mr. Thapliyal delineated more on the rising demand of packaging and the need to incorporate nascent technological trends to fulfill increasing demand of quality. He said, “The recent trend is that the product and the package have become interdependent. We can’t think of any product without its packaging. Therefore, with increase in demand of the packaging, the technological requirements have also increased. With the increasing demand today, it is necessary to borrow the knowledge from other branches of science to come up with innovations in packaging. Paper and paperboard manufacturers, packaging professionals, suppliers and users must jointly address issues of product quality, the use of packaging materials, right sized packaging, environmental performance, and cost reduction.”

Taking his main topic of technology innovations and absorption ahead Mr. Tapliyal said, “Paper and paperboard manufacturing has been revolutionized over the decades and inventions in various areas have shaped the industry into a modern process industry. The innovations in the area of process technology, automation and control, ecosystem management have transformed the industry. As a result, the industry utilizes state-of-the-art fibre lines and paper machines to produce quality paper products.

Taking his main topic of technology innovations and absorption ahead Mr. Tapliyal said, “Paper and paperboard manufacturing has been revolutionized over the decades and inventions in various areas have shaped the industry into a modern process industry. The innovations in the area of process technology, automation and control, ecosystem management have transformed the industry. As a result, the industry utilizes state-of-the-art fibre lines and paper machines to produce quality paper products.

“Advances in automation and control have also made it possible to collect data, analyze them, and obtain guidance for optimization of the processes in order to produce quality products to meet almost all packaging requirements. Developments in the area of environmental management have enabled the industry to meet all regulatory environmental compliances for the process and products. Innovations and developments in the area of digitalization such as smart equipment, smart products, and network for connectivity are now getting the industry ready for the future. We also refer it as the Industry 4.0. This is the vision of the future industry that will be characterized by the self-organized intelligent ecosystems in a future concept paper mill.

Moreover, as part of Industry 4.0, all parts of the industry value-chain, viz. raw material, processing equipments, products, and consumers will be built as interconnected clusters that will continuously send and receive information from each other. The five important elements of the industry are– the smart equipment, networking and connectivity, value chain integration, smart products, and analytics. These five elements of the industry will interact and continuously develop updated algorithms based on the real-time inputs.

“While some of these opportunities may seem to be achievable only in the distant future some of them already exist today. Some progressive sectors such as IT, aerospace and the automotive industry have already reached the stage of business plan development of the concept of Industry 4.0. The pulp and paper industry is still at a very early stage with regard to the Industry 4.0 and is building up strategic awareness. Some participants from Japan and other developed countries have started to build up strategic awareness and they have started signal yet unconnected projects in this direction.”

Mr. Thapliyal shared some information on innovations in packaging products. He said, “Papermilk is a product that includes milk fibre in the paper making process. This is a very special paper with excellent ductile properties to suit all kinds of printing techniques and packaging solutions. This is being produced by Gruppo Cordenons Spa in Italy. Likewise, GreeNest is a green egg box made by Huhtamaki in the Netherlands. This innovative moulded box is based on 50 percent grass fibres sourced from natural reserves. Then, we have Bicycle Helmet, which delivers on protection by using a combination of hi-tech, renewable materials derived from the forest. With an outer shell made of 3D-veneer, the helmet has paper based straps and an inner cushioning made from nano-cellulose foam.

“We also have a Cookie Box with RFID made by Stora Enso in Finland. Then, there is Micro Fibrilated Cellulose product, which can be used as a substitute from the petrochemical industry. The dream of bio-economy is being realized. Nano Crystalline Cellulose — occurring in the waste sludge from the papermaking process — can form highly complex structures which make it very good for applications such as foams. Companies are capitalising on this characteristic to develop environmentally-friendly foams which are light, strong, water and fire resistant.

Paperex South India: To benefit People by Connecting

Director of Tamil Nadu Newsprint and Papers Ltd.

The guest of honor Mr. S. Sivashanmugaraja, IAS and Managing Director of Tamil Nadu Newsprint and Papers Limited said, ” The paper industry in India is one of the most important industries and has been contributing substantially to the industrial production as well as to the exchequer. There are more than 850 paper mills in India producing nearly 17.5 to 18 million tonnes annually. The paper industry in India is self-sufficient in most of the categories, except for some special grades of paper which continue to be imported.”

Mr. Sivashanmugaraja further said, “The paper industry in South India is probably larger in terms of number of paper mills and also producing all varieties of papers. The paper mills like any other industry are facing number of problems. The industry is more than a century old and obviously it does require modernization and upgradation, particularly in the present context when the industry is expected to compete with international players both within the country and outside. I am sure the experience of this forum will certainly provide a platform for technology seekers and buyers to meet on a common platform and see what can be suitable to them.

“I am told that the Paperex, which is a major event held in Delhi, has been instrumental in transfer of state-of-the-art-technology in the Indian industry. Therefore, I compliment the organizers for having a similar version of a major event in South India. This would benefit the paper mills technology-wise and people connected with the paper industry to know what is all going around in the pulp and paper industry around the world.

“I am also happy to note that along with exhibition, a conference is being organized with the theme recycling and packaging. The theme recycling and packaging was chosen as the key areas in the context of personal growth of paper industry. While one is on raw material and the other is on the emerging market in the field of packaging. In TNPL, we have setup a new board plant keeping in view the growth in the field of packaging industry. We have setup modern state-of-the-art technologies to manufacture boards of international quality. We will serve the markets within the country and abroad, and will meet the quality expectations of the MNCs and other major converters engaged in the programs in India.

“I am also happy to note that along with exhibition, a conference is being organized with the theme recycling and packaging. The theme recycling and packaging was chosen as the key areas in the context of personal growth of paper industry. While one is on raw material and the other is on the emerging market in the field of packaging. In TNPL, we have setup a new board plant keeping in view the growth in the field of packaging industry. We have setup modern state-of-the-art technologies to manufacture boards of international quality. We will serve the markets within the country and abroad, and will meet the quality expectations of the MNCs and other major converters engaged in the programs in India.

“It is seen that packaging segment is growing fast as compared to writing and printing. With the advent of e-commerce and e-retailers the requirements of packaging have increased and therefore I feel that the future for the packaging industry will be brighter. However, mentioning the progress of packaging I would like to mention the problems faced by the industry, particularly on waste paper. The industry is heavily dependent on recycled fiber, the availability of which is very limited and we are required to import huge quality of waste papers to meet our requirements. The recovery rate in our country is only 26-27 percent as against the consumption of nearly 18 million tonnes. There is a need for improving the recovery rate, for which both the governments — the central and the state — as well as municipal corporation and associations need to work as a whole.

“Another important point that comes to my mind is the pollution abatement in the pulp and paper industry. Paper industry is considered to be highly polluting and no paper mills without chemical recovery is allowed to function. The pollution control norms are becoming stricter and the industry must fight hard to meet the pollution norms for the betterment the society that we live in. At the end, let us get committed to intensifying the three Rs — reduce, recycle and reuse — and raise the percentage of recovery of waste paper from 26 to 40 percent. ”

Technology Adoption for World Class Quality

The chief guest Mr. N Gokulakrishnan, Hon’ble Member of Parliament from Puducherry also addressed the gathering. Mr. Gokulkrishnan also an entrepreneur and Chairman of Nithya Group of Industries producing paper and corrugated cartons. He said, “The importance of the exhibition is to bring all machinery manufacturers, technologist and investors under one roof to inculcate technology upgradation in the paper industry. We should also showcase the latest technological advancements in the industry for all over the world and help its adoption in the industry to improve standards of the products. This should enable us to catch up with the global market. India is a fast growing market and is expected to grow above six percent per annum over the next few years. For a nation aiming to become a leader in the world economy, our contribution though is only three percent of world’s paper production and therefore will have to go up in achieving the goal.

“The kraft papers requirement is expected to increase in the years to come. The demand for packaging paper and board segment is increasing. W&P segment demand is also expected to grow at higher rates in the years to come. I am sure that the Paperex South India 2018 would serve as the morale booster for the paper industry. I expect the participants to be benefited from the proceedings. I would like to thank organizers for having taken efforts to bring Paperex event a grand success and also congratulate them for their marvelous work.”