Suppliers often provide only single Yankee service components like grinding or leave the customer “alone” with the Yankee after purchase. This is a pity as a well-maintained Yankee offers a high potential for improved runability and efficient production — a remarkable competitive advantage for the customer. With its comprehensive Yankee service, ANDRITZ focuses on the overall added value of Yankees: from calculation, to manufacturing, coating (PrimeCoat Stratos thermal coating), operation, and optimization.

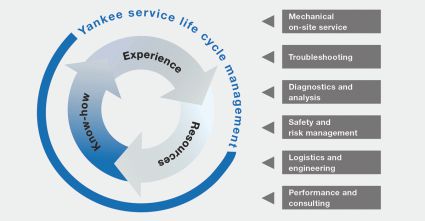

The ANDRITZ Yankee service helps to improve the machine’s efficiency and the Yankee’s performance. They are valid for all kinds of Yankees (tissue, paper, MG-paper, tobacco machines), no matter if cast or steel, no matter if new or old and no matter which brand. The service packages include solutions and support for upgrades and replacements, safety, production, and analysis (e.g. on the run measurements). The following graphic shows the service offers in detail:

Mechanical On-site Service

Apart from grinding services and exchange of spare parts, ANDRITZ offers leakage repairs, Yankee head testing and repairs, press NIP calibration, and doctor blade adjustment. A real highlight is the PrimeCoat Stratos thermal coating solution that can be used for full-face coating, edge and spot repair.

Mechanical on-site service in brief:

- Grinding of the Yankee

- Metalizing

- Spot repair

- Upgrade and repair of internal parts

Safety and Risk Management

Annual or biannual checks are needed to confirm that the condition of the Yankee is in compliance with the pressure vessel safety regulations and other global standards (e.g. by insurance companies).

Furthermore, an acoustic measurement can identify cracks independently on a steel or cast Yankee, provided if there is any serious damage.

Safety and risk management in brief:

- Calculation of the Yankee’s life time

- Inspections like ultrasonic, metallurgical, and acoustic measurement (replaces the hydrostatic test frequently requested in many countries)

- Services requested by the major insurance companies

Performance and Consulting

When analyzing measurement results, the capability of seeing the bigger picture, meaning the production system and mill as a whole, is of utmost importance. Thus, ANDRITZ does not give recommendations only for the Yankee, but for the whole drying system (Yankee incl. hood, re-evaporation system, etc.) and highlights potential for energy savings (like the combination of steel Yankee and steam heated hood) and improved runability.

Performance and consulting in brief:

- Calculation of the drying limit

- Evaluation of the machine’s performance and runability potential in respect of drying costs

- ANDRITZ has developed an energy management system (EMS) to analyze and monitor energy consumption and costs of the complete plant.

Troubleshooting

In case of problems, the ANDRITZ experts are able to find solutions covering not only the mechanical side, such as Yankee surface and Yankee internal inspections, but also control logic issues in the steam and condensate system as well as automation issues. In addition, the dewatering rate can be checked and compared with the designed optimum running conditions. As ANDRITZ covers the whole process, even runability issues caused by coating chemicals, steam and condensate, chemical treatment, or doctor issues can be solved.

Operational challenges:

- There are leakages at the steam and condensate system?

- The thermos-compressor is not working properly?

- There are vibrations around the Yankee and the press rolls?

- The drying performance has dropped?

- There is dramatic wear on the doctor blades and or Yankee itself?

Our Yankee service experts team can not only resolve these issues, they are also specialized in diagnostics and analyzing the root of cause.

Diagnostics and Analysis

To maintain or improve runnability, safety, and performance, very specific inspections, measurements or calculations are needed, which normally go beyond a mill’s capacities. In addition, more and more insurance companies require annual checks of key components like the Yankee. ANDRITZ can take on a variety of duties, for example Finite Element Analysis (FEA) for static and dynamic loads on the Yankee.

Diagnostics and analysis in brief:

- On-the-run measurements (OTR) to check the Yankee’s shape and temperature profile and determine the right time for regrinding and metalizing. Crowning issues can be measured and resolved at the same time.

- Operating performance of the condensate removal system can be measured during regular operation.

- Measurements of the thickness and evenness of the organic coating.

Extensive Experience and Research

By using the Finite Element Analysis, ANDRITZ is able to conduct crowning curve calculations for cast and steel Yankees and for pressure rolls. In addition, a complete stress analysis evaluation can be conducted on the static and dynamic loads on the Yankee. Derating calculations of cast Yankees and fatigue stress analysis are also possible. The simulation includes the thermal stress, the mechanical stress, and the stress coming from the heating process. With these calculation models, one is able to simulate most of the stresses arising during production of the paper. This allows a well defined dimension — especially shells wall thickness — to achieve the optimum ratio of safety to drying efficiency.

Logistics and Engineering

Unique logistics and engineering concepts for rebuilds and new installations offer a way of making the impossible possible. Nowadays, there seem to be no limits regarding Yankee sizes in production. Only transport restricts size and efficiency visions. Narrow streets, tunnels and weight regulations limit manufacturers in their possibilities. ANDRITZ has accepted the challenge and, with the world’s largest steel Yankee (22 ft. in diameter, installed at Zellstoff Pöls AG, PM2, Austria), it has proved that its logistics concept really pays off (see graphic 05).

Logistics and engineering in brief:

- Customized solutions for rebuilds

- On-site assembly to avoid transportation restrictions

- On-site welding for large Yankees (e.g. 18 – 22 ft. in diameter)

- Holistic engineering approach including all key elements like steam and condensate systems, doctors, coatings, press concepts and much more.

More than Just Regular Service

The ANDRITZ Yankee lifecycle management is more than just regular service. It starts by being near the customer, ready to listen carefully to his needs and detecting together the fields of action.It also includes customized solutions for new Yankees and rebuilds and escorts the customer through the complete Yankee lifecycle.

Unique in the Market

assembly directly at the customer.

ANDRITZ is the only supplier able to deliver an “all out of one hand” comprehensive service: from engineering to manufacturing, transport, start-up assistance and maintenance solutions. Coating and grinding are even possible on-site, directly at the customer.