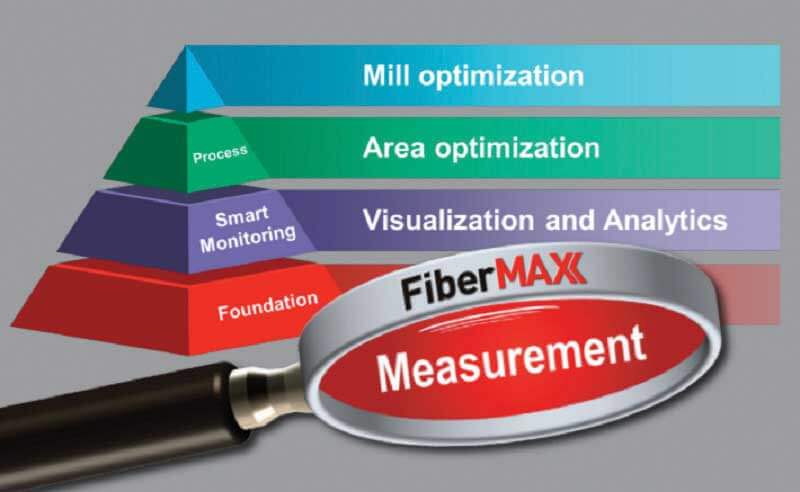

FiberMAX by BTG features a thorough survey of all furnish consistency control positions, which are based on a holistic view of the process.

BTG has brought FiberMAX, which is a diagnostic service to identify opportunities for reducing fiber cost and variability, including stabilising paper quality for paper manufacturers. During the papermaking process, the control loops for fiber mass flow hold key importance for stable production and operations.

In FiberMAX, a thorough survey of all furnish consistency control positions, which are based on a holistic view of the process, is included in the system. Parameters like process measurements, sampling and calibration, and control loop performance are being evaluated and compared to best-practice benchmarks.

Watch: Evolution of Paper Based Packaging

In order to present detailed recommendations for improvements, the FiberMAX team identifies the sources of variability. Moreover, since FiberMAX is a flexible diagnostic tool, the system is applicable for any type of paper production line and paper grade.

Also Read: Stora Enso Ingerois Mill to Improve Operational Performance with BTG’s dataPARC

In the past years, FiberMAX has been deployed in a number of pulp and paper mills across the globe. The system has proven to be a very valuable starting point for many improvement projects, including Industry 4.0.

Switzerland-headquartered BTG Group is a multinational provider of integrated, highly specialised process solutions for the global pulp and paper industry. The company assists the pulp and paper manufacturers in achieving sustainable gains in business performance with their technology-centric solutions.