The company has set up India’s first on-site PCC Plant in a recycled pulp based paper mill; as of now, the company has successfully set up six satellite plants which include the two on-site plant of PCC and WGCC set up in Bangladesh, says Mrs. Arushi Jain.

Gulshan Polyols Limited, incorporated in 1981 as Gulshan Sugars & Chemicals Limited, is among market leaders, manufacturing precipitated calcium carbonate (PCC) and wet ground calcium carbonate (WGCC). Its business, spread over 35 countries, comprises starch sugars, calcium carbonate, agro based animal feed, alcohol and on-site PCC plants.

The company claims to be the first Indian company to have set up its own R&D and have introduced PCC for use in paper making in powder form, and then to have introduced the fine quality of ground calcium carbonate (GCC) in powder form for its use in coated paper as coating pigment, first time in India.

The company has set up India’s first on-site PCC Plant in a recycled pulp based paper mill. Paper Mart recently interviewed Mrs. Arushi Jain, Director, Gulshan Polyols Ltd. where she gave us some interesting details about the company and its objectives. Here are excerpts:

First share with us the journey of Gulshan Polyols as a manufacturer of specialty chemicals.

Gulshan Polyols Limited (GPL) is a multi location, multi product manufacturing company and has become a market leader in most of its products in India with global presence in 35 countries, across 3 continents. Its business portfolio covers starch sugar, calcium carbonate, agro-based animal feed, alcohol, and on-site PCC plants.

The company was incorporated in the year 1981 in the name of Gulshan Sugars & Chemicals Limited (GSCL) with primary business of manufacturing calcium carbonate at Muzaffarnagar with installed capacity of 2100 tonnes per annum, and expanded its capacity over the period up to 150000 tonnes per annum. Going forward, GSCL was merged into Gulshan Polyols Ltd, a Public Ltd. Co. listed on BSE and NSE.

As a company, we try to fulfill customers’ need through our economic, tailor-made technical solutions and have pioneered the way for the multipurpose use of precipitated calcium carbonate (PCC) and wet ground calcium carbonate (WGCC), including paper applications.

The process of product refinement and improvement is continuous, and Gulshan is supposedly the first company in India to have set up an in-house R&D facility for the purpose. Moreover, we have introduced PCC and ground calcium carbonate (GCC), both in powder form, to be used in making paper.

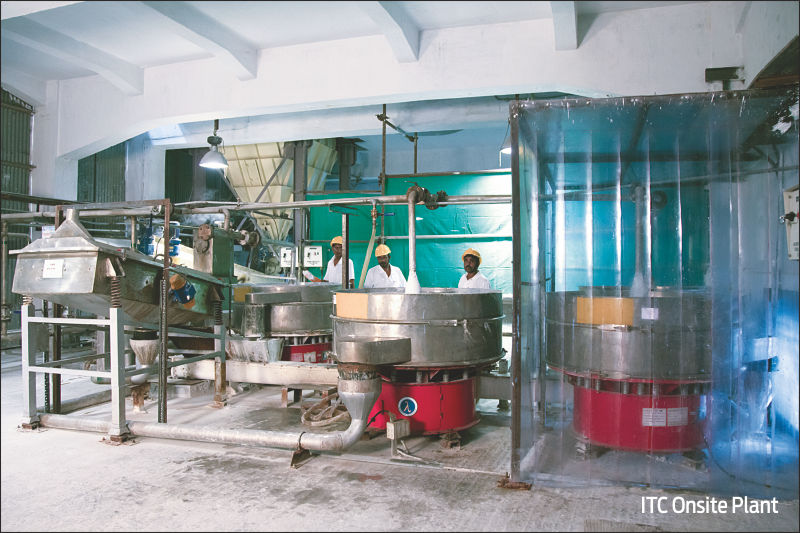

And going one step ahead, the company has set up India’s first on-site PCC plant in a recycled pulp based paper mill. The company, as of now, has successfully set up six satellite plants which include the two on-site plants of PCC and WGCC set up in Bangladesh for Bashundhra Group of Companies with installed capacity of 20,000 dry tonnes per annum and 30,000 dry tonnes per annum respectively. These plants are running successfully.

We have our own 15 MW captive power plant for uninterrupted production and supply of good quality power at its Muzaffarnagar and Bharuch facilities. We are self-sufficient in terms of power and don’t depend much on grid supply.

As a producer of starch derivatives and calcium carbonate, which industries do you serve? Please elaborate on your clientele and how they use your compounds.

Gulshan’s extensive product repertoire is aimed at serving a wide variety of industries, namely sweeteners, paints, paper, pharmaceuticals, plastics, personal care, nutrition enhancer for humans and cattle, etc. GPL has an impressive clientele comprising of Colgate, Palmolive, Hindustan Unilever Ltd, ITC, Asian Paints, etc. We have recently been recognized as ‘Star Export House’ by the Government of India for consistent export of our products to various parts of the world.

We produce starch for its captive use to make sweeteners like Sorbitol 70 percent, dextrose monohydrate, maltodextrine, rice syrup and liquid glucose.

PCC and WGCC are being produced for use in specialty paper and paper applications. Mainly these products are produced at a satellite facility and pumped in slurry form directly to mills in vicinity to provide economical solutions with enhanced quality and at the same time saving the cost involved in drying.

Apart from on-site product, such products are also produced at our merchant plant facility in powder form and in loose packing to cater to small customers. The company has four merchant plants at different locations to give the logistic advantages to the end users. All these plants are strategically located nearby raw material reserves which are enough to last for many years to come, and the quality (of raw material) is at par with international standards.

Our two sites Bharuch and Abu Road are near to port. This gives us the flexibility of using either imported or indigenous raw material, thereby making it easy to serve customers with the right product at economical price, which is our utmost priority.