Confederation of Indian Industry (CII) held its fourth national conference on pulp and paper titled, “Moving from Trade-offs to Win-Wins in Water Management”, at The LaLiT, Delhi, on July 2, 2019. The purpose of the conference was to build awareness about advanced treatment technologies for water reuse and resource recovery among pulp and paper manufacturers in India. Speakers at the conference focussed on subjects such as tools and techniques for water reuse and recycling, development of indigenous technology, emerging reforms and policies, the best practices in water and wastewater management in the pulp and paper sector and means for integrating technology providers with technology users.

The Inaugural Session

The Inaugural Session

In his welcome address at the conference, Sanjay Singh, Conference Chairman and Divisional Chief Executive, ITC-PSPD, said, “80 percent of river basins in the country are water stressed. In many parts of India, ground water is declining by about 3 feet per year. Currently, around 600 million people in the country face extreme water-scarce conditions. The quality of water is also deteriorating; it is not fit for human consumption. Despite these challenges, we in the paper industry work hard to make the industry grow.

In his welcome address at the conference, Sanjay Singh, Conference Chairman and Divisional Chief Executive, ITC-PSPD, said, “80 percent of river basins in the country are water stressed. In many parts of India, ground water is declining by about 3 feet per year. Currently, around 600 million people in the country face extreme water-scarce conditions. The quality of water is also deteriorating; it is not fit for human consumption. Despite these challenges, we in the paper industry work hard to make the industry grow.

“The demand for packaging has a direct correlation with GDP. India’s GDP is growing at the rate of 6 to 7 percent per year. We want the GDP to grow at 9 percent so that our average income increases and the quality of life in India improves. The basic need of water has to be met. As you already know, the paper industry in India is no longer a water guzzler. It used to be a water guzzler once upon a time. A lot of work has been done by many of us in the last 25 to 30 years to reduce water consumption to the maximum extent. In the past, big paper mills used 120 to 130 m3/t of paper; now it has come down to 35 to 40 m3/t of paper. Still there is a lot of work to be done in this direction. There is still scope for reducing water consumption.

A lot of work has been done by many of us in the last 25 to 30 years to reduce water consumption to the maximum extent. In the past, big paper mills used 120 to 130 m3/t of paper; now it has come down to 35 to 40 m3/t of paper. Still there is a lot of work to be done in this direction. There is still scope for reducing water consumption.

“I was in Finland last week. I was attending a technical conference where one of the biggest equipment suppliers in the world was sharing information about a new technology with us. This technology, as I was told, could do all sorts of things, including quality improvement, reduction of energy consumption by 30 to 40 percent and what have you. But not a single word was said about reduction of water consumption in the pulp and industry. For us reduction of water consumption is such a critical issue. The question that popped up in my mind was why are these guys not interested in developing technology for reduction of water consumption? When I asked that question, I was told that plenty of water is available in Finland and Sweden and so, reduction of water consumption is not a focus area for them. So, paper manufacturers in India will have to find ways and means of reducing water consumption on their own. We also need to push our equipment suppliers to provide us with equipment that that uses less water. This is not a difficult job. We just need to focus on it.

“The most challenging issue is water conservation. If the rivers dry up and there is water crisis, the axe will fall on industry. As a paper manufacturer, you will say I did this and I did that to reduce water consumption, but the government will just not listen to you. It will ask you to shut down your mill because agriculture takes priority over industry. So, the industry must try to conserve water, recharge groundwater and reduce water consumption in the agriculture sector.

“The pulp and paper industry must go beyond reducing water consumptions in just its mills and plants; it must try to reduce water consumption in the agriculture sector as well. People in the agriculture sector waste water and that is mainly because the government has given them full control over the use of water. Many water-saving and water-conserving practices can be adopted in the agriculture sector. If these practices are fully adopted, the water table will rise and water will be freely available. How can we keep recharging groundwater? How can we reduce consumption of water in the agriculture sector? These are the questions that paper manufacturers must address. As paper manufacturers, we need to spend part of the money we spend on CSR on reduction of water consumption in the agriculture sector. In a particular plant of ours, we have started doing this exercise and we have been able to achieve a lot – around 35 to 40 percent reduction of water consumption in the related agriculture area. We did that over a period of two years.

“Briefly then, mills need to keep recharging ground water in all possible ways. They also have to go beyond conserving water within the industry; they need to make special efforts to save and conserve water in the agriculture sector as well.”

Speaking at the inaugural session of the conference, Kapil Narula, Executive Director and CEO, CII-Triveni Water Institute, said, “As far as the geographical spread of the installed capacity of the pulp and paper industry in India is concerned, around 70 percent of the total installed capacity is concentrated in states like Andhra Pradesh, Gujarat, Odisha, Karnataka, Maharashtra and West Bengal. Almost 60 to 70 percent of India receives less than 600 mm of rainfall while 30 to 40 percent of India receives a high rainfall. The average comes out to be 600 mm. The variability of rainfall in India is very high. Our core analysis shows that 30 to 40 percent is the coefficient of variability, which means that areas that are receiving less rainfall would on average experience a drought once in three years and the drought years can go up from one in three years to two in five years – even three in five years. This is a scary picture. So, in India, we have a much skewed distribution of rainfall and around 70 to 80 percent of pulp and paper plants are in categories of high to extremely high water stress zones with a high coefficient of variability of rainfall.

Speaking at the inaugural session of the conference, Kapil Narula, Executive Director and CEO, CII-Triveni Water Institute, said, “As far as the geographical spread of the installed capacity of the pulp and paper industry in India is concerned, around 70 percent of the total installed capacity is concentrated in states like Andhra Pradesh, Gujarat, Odisha, Karnataka, Maharashtra and West Bengal. Almost 60 to 70 percent of India receives less than 600 mm of rainfall while 30 to 40 percent of India receives a high rainfall. The average comes out to be 600 mm. The variability of rainfall in India is very high. Our core analysis shows that 30 to 40 percent is the coefficient of variability, which means that areas that are receiving less rainfall would on average experience a drought once in three years and the drought years can go up from one in three years to two in five years – even three in five years. This is a scary picture. So, in India, we have a much skewed distribution of rainfall and around 70 to 80 percent of pulp and paper plants are in categories of high to extremely high water stress zones with a high coefficient of variability of rainfall.

National Green Tribunal (NGT) is taking very stern action on groundwater, especially for over exploited areas or critical areas. All the areas that show continuous decline and are extracting water over and above the natural recharge are classified as critical or over exploited areas. Almost 60 to 70 percent of our plants, which are responsible for 70 percent of the installed capacity in the pulp and paper industry, lie in groundwater-stressed zones.

“We have a few water-related challenges to face. Water is increasingly becoming scarce. By 2030, India’s water demand is projected to be twice the available supply, implying severe water scarcity leading to a 6 percent loss in GDP. As a result, the situation for the industry will become more difficult in terms of standards and regulations. We already have stringent guidelines to regulate and control groundwater extraction and standards for effluent discharge from existing and upcoming Sewage Treatment Plants (STPs). The role of NGT is also rising. We also see the judiciary taking key decisions in areas related to resource management – and water is one of the resources. Water conservation has become a key priority for the government. The challenges are there for us, but there is a huge opportunity for us to invest together in shaping the future for the betterment of the industry and the world.

“Our water audits clearly show that 40 to 50 percent reduction of water consumption in the pulp and paper industry is possible and economically viable. This does not require a huge investment. So, we need to conduct our water audits regularly. Also, when you look at what you have done inside the plant, do not forget the watershed and the ecosystem you are a part of. Apart from the agriculture sector, there are many industries in the same watershed. Your plant is just one plant in that watershed, but that should not take away your responsibility of understanding the health of your watershed. There are many cases of plants getting shut down because of unhealthy watersheds.”

Our water audits clearly show that 40 to 50 percent reduction of water consumption in the pulp and paper industry is possible and economically viable.

In his address at the conference, Rakesh Kumar Jain, Technical Expert, International Centre for Inclusive and Sustainable Industrial Development (IC-ISID), United Nations Industrial Development Organization (UNIDO), said, “I strongly feel that the importance of water can never be stressed enough. It is important to stress today the critical role that technology can play in responsible wastewater management for the Indian paper industry.

In his address at the conference, Rakesh Kumar Jain, Technical Expert, International Centre for Inclusive and Sustainable Industrial Development (IC-ISID), United Nations Industrial Development Organization (UNIDO), said, “I strongly feel that the importance of water can never be stressed enough. It is important to stress today the critical role that technology can play in responsible wastewater management for the Indian paper industry.

“The Indian paper industry is among the fastest growing industries in the world. Despite various challenges being faced, the industry has been growing at an average growth of 7 percent against the global average 2 to 3 percent. The industry ranks fifteenth among the top global paper producers, contributing around 4 percent of the global paper production accounting to around 20 million tons annually. The Indian paper industry is unique and highly fragmented, dominated by small and medium enterprises (SMEs), unlike the global paper industry, as a majority of Indian paper mills are small – as low as below 50 TPD.

“As a large water consumer, the Indian paper industry has been progressively improving its water usage while achieving the stipulated benchmarks. One of the major challenges before the industry is on the environmental front, which the industry has been able to address gradually by way of adopting various measures, such as adoption of cleaner production technologies and processes coupled with treatment of effluents streams employing available waste treatment technologies.

ALSO READ: Paper Formulation Technology is a Key Driver for Sustainable Packaging.

“Currently, conservation and reuse of water resources have emerged as an important component of proper environmental management owing to the shortage of water and conflicts over water usage. There is a worldwide tendency towards the development and application of advanced wastewater treatment systems that enable significant improvements in the final wastewater quality by applying standards that are increasingly becoming restrictive or enabling the reuse of treated wastewater in the production process itself or in other beneficial uses rather than discharging it into water bodies. The idea of totally or partially closed water circuits in the pulp and paper industry has come to stay. The driving force for fresh water minimization might be more efficient processes, lack of water resources, fresh water and wastewater costs as well as stringent norms, but today all agree that it has to be done.

“Though a lot has been done during the last decade and many of the Recycled Cellulose Fiber (RCF)-based paper mills claim to operate with specific water consumption as low as less than 10 m3/tp, these mills are faced with various issues and challenges related to poor quality of the internal process water, build up of TDS, TSS and microbial slime, foul smell and stickies, with negative impact on product quality, productivity and the overall process efficiency of the paper mills.

Even though the membrane filtration process has already been used in the European and North American paper industries, its adoption in Indian paper mills may not be straightforward because of certain factors.

“Pertaining to the quality of the process water being recycled in the mill, it is not clear what the tolerance limits for the water quality is in different mills. Must the reused water really be potable? Or could the reused water contain “something” without harming the product or the viability of the process? Does that something differ from mill to mill? On the basis of the knowledge available today, it seems that no measured value commensurately describes the papermaking process in such a way that common conclusion could be drawn.

“The global tendency is towards the development and adaption of the best available advanced wastewater treatment technologies, such as membrane filtration process and the hybrid process combining it with other techniques.

“Even though the membrane filtration process has already been used in the European and North American paper industries, its adoption in Indian paper mills may not be straightforward because of certain factors. Let’s take a look at these factors. The first one is diversified use of fiber mix such as agro, wood, and RCF – different characteristics of the wastewater streams with higher pollution loads in terms of TDS, color and COD. Next, membranes, being sensitive to the quality of feed water, require rigorous pre-treatment, selection and appropriate configuration of the membrane.

“UNIDO, as a part of its paper project, recently implemented in close coordination with CPPRI and the Indian paper industry, identified membrane filtration process as an emerging potential technology for water and wastewater management. Subsequent to the successful bench level demonstration of the membrane filtration process at CPPRI and dissemination of the findings to the Indian paper industry across the country, UNIDO now proposes to demonstrate the membrane filtration process on a larger pilot level, capacity around 100m3/day, in identified paper units located across the country.

“The project aims to customize the technology in the Indian context providing a better understanding of operational aspects such as required protocol for pre-treatment of the effluent streams, membrane fouling and chocking tendency and its cleaning mechanism, and membrane configuration and energy requirement. The information would help in designing, developing and furthering up scaling of membrane technology in the Indian context.

“The successful demonstration should help in confidence-building for adoption of the membrane process and provide an opportunity to address issues related to water scarcity, maximum possible recycling of the process water without negative effect on the quality, productivity and process efficiency while meeting ambitious reduction targets for industrial water use as outlined in Ganga River Basin Charter and allow mills to meet stricter discharge norms for water use and discharge.

“Let’s not forget that water is absolutely essential to Life. We have found alternate energy, but finding an alternative to water will not be easy.”

“Let’s not forget that water is absolutely essential to Life. We have found alternate energy, but finding an alternative to water will not be easy.”

In his address at the conference, Bipin Prakash Thapliyal, Director, Central Pulp & Paper Research Institute, said, “Water is one of the essential resources. Rising population and economic development has caused significant increase in water demand in recent years. At the same time, climate change has also contributed towards lower overall water availability. The recent Composite Water Management Index (CWMI) report released by the NITI Aayog in 2018 indicates that 21 major cities, including Delhi, Bengaluru, Chennai and Hyderabad, are racing to reach zero groundwater levels and by 2020. It will affect access for about 100 million people. The alarming situation is that about 12 percent of India’s population is already living the ‘Day Zero’ scenario due to excessive groundwater pumping, an inefficient and wasteful water management system and years of deficient rains. The CWMI report also states that by 2030, the country’s water demand is projected to be twice the available supply, implying severe water scarcity for hundreds of millions of people and an eventual 6 percent loss in the country’s GDP.

“The water crisis or scarcity is a matter of concern for water-intensive industries, and the paper industry is one of them. The paper industry has been traditionally water-intensive. In India, it has been categorized as Grossly Polluting Industry (GPI). As you already know, water plays an important role in papermaking. It is used in cleaning, screening, stock dilution and finally paper sheet formation. Around 80-85 percent of water is discharged as effluent and the rest is lost during the papermaking process.

“In the Indian context, the major reasons for high water consumption are use of mixed raw materials, making optimization of process operations difficult; the low level of technology and equipment due to low scale of operation; lack of optimized process conditions; use of low capacity multiple paper machine; and lack of reuse or recycling practices in the paper industry. Water is a precious resource. It should be noted that further abuse of water will lead to permanent ecological and environmental damages and will impose restrictions on its industrial use. So, for the sustainability of the industry, we need to conserve water and use it judiciously.

“Though paper mills have significantly reduced the consumption of fresh water from the level of 250 to 300 m3/t of paper in 1990 to the present level of 10 to 80 m3/t of paper, still these figures are higher than the international benchmarks. As per the trends in the last two to three decades and considering the average growth of 7 to 8 percent in paper production by the Indian paper industry, it is estimated that to meet the growing demand, the annual paper production will increase at a rate of around 1.0 million tonnes per annum and accordingly paper production is expected to be 21 million tonnes in 2020, 25 million tonnes in 2030 and 45 million tonnes in 2050.This will call for an overall fresh water consumption increase by 20 to 22 percent during 2020-2050.

“As such there is an urgent need for the industry to adopt appropriate water management tools, technology and practices to ensure sustainability in the critical scenario of water scarcity. In general, the paper industry needs an integrated approach to achieve water minimization. This includes quantification of actual water consumption, identification and optimization of process operations requirements, process changes or modifications, reuse and recycle of backwater or wastewater, and regeneration of process water quality from backwater or wastewater through advance treatment.

Surely, there is a need for a paradigm shift. We urgently require a transition from the supply-and-supply-more-water provision to measures that lead towards efficient use of water, reduction of wastage, recycle and reuse of process water after proper treatment to achieve near-zero discharge.

“Till the recent past, the low cost of water has been one of the major deterrents in the water conservation efforts made by the Indian paper industry. However, due to declining ground water availability, regulatory pressures and stringent norms, and an increased emphasis on saving the rivers, water conservation has now become priority agenda for the paper industry.

“Surely, there is a need for a paradigm shift. We urgently require a transition from the supply-and-supply-more-water provision to measures that lead towards efficient use of water, reduction of wastage, recycle and reuse of process water after proper treatment to achieve near-zero discharge.

“CII has taken various initiatives to provide innovative water management practices and solutions for the industry, and today’s Conference is a welcome move to bring together diverse stakeholders from the industry and the government, technology providers and some of the leading practitioners.”

In his keynote address, Ravi Singh, CEO and Secretary General, WWF-India, said, “The time has come when more and more partnerships will be needed and people will have to come together to find a solution to the water-management crisis in India. The industry already has a few people who are trying to deal with this issue.

“In order to address this issue, we need to understand the concept of basin management. When CII started its water initiative, it was quite difficult to make people understand what basin management was all about. Someone was conserving water at the middle of the basin, while at the top of the basin, that is, upstream, pollution was causing severe damage. Under-standing which basin we are from and dividing areas accordingly will make a lot of difference.

“Of late, there has been a lot of discussion about water management and conservation, and the government is taking all necessary steps to improve the state of water management in India. Let me tell you, India does not suffer from water shortage. The problem stems from poor water management. The industry needs to find a solution to this problem.

“In the last decade, India witnessed a drastic shift in the demand and consumption of water. Nearly 25 per cent of the country’s population lives in water-scarce areas, where the per capita availability of water is less than 1,000 cubic meters per year. Fourteen of the twenty major river basins in India are already water-stressed, and it is estimated that they will be moving towards extreme water scarcity by 2050.

The time has come when more and more partnerships will be needed and people will have to come together to find a solution to the water-management crisis in India.

“The projected increase in consumption of water by industry that will substantially increase risks to both industry and river basins, which was 42 km3 in 2000, will touch up to 161 km3 by 2050. The impact of water availability and its management are very local and lead to company-related risks which are location- and sector-specific. There is a need to better understand the shared risks across the river basin, sub-basin, lake or the groundwater system in which a company’s facilities are located.

“The industrial consumption currently accounts for only about 8 percent of freshwater consumption in the country. Water being a shared resource can pose substantial risk to companies’ operations and profitability. It is a shared risk between multiple and often competing water users such as households, agriculture, industry, and the environment. These are based on physical, regulatory and reputational risks.

“The Indian pulp and paper industry is known to consume about 275 to 490 cubic meters/BDMT of water, which is almost five times the global best. There are approximately 600 paper mills in the country, out of which about 66 percent are small-scale, 24 percent are medium-scale and only 10 percent fall under large-scale mills. As per the latest survey, about 60 percent of total paper production in the country is from large-scale mills, while the balance 40 percent is produced by medium and small-scale mills.

“Eighty five percent of the water consumed by large-scale Indian paper mills comes from surface water, so these mills are mainly located near rivers. The fact that these mills are located near rivers and withdraw large amounts of water has already contributed to increased stress levels in some rivers, including Bhadra, Cauvery, Kali, Kotlab, Tungabhadra and Wardha, thereby causing some of these basins to be classified under ‘very high’ water stress. It was found that close to 40 percent of large-scale mills have been implicated for causing water stress and pollution.

“The pulp and paper sector constitutes around 2.26 percent of overall water use in the industrial sector. The wastewater discharged by the Indian pulp and paper industry ranges from 118 cubic meters to 280 cubic meters/BDMT, which is approximately three times more than that of the European paper and pulp industry. On average, the BOD, COD, TSS and AOX levels are 9.3 times, 4.5 times, 15 times and 4.8 times respectively higher than the best practices followed.

“The total effluent discharge from the pulp and paper industry in the Ganga basin alone is estimated to be over 200 MLD. As per CPCB’s report on Pollution Assessment: River Ganga, 2013, the pulp and paper sector dominates in terms of water consumption – 27 percent of total – and wastewater generation – 40 percent of total – in the Ganga basin. As a result, the pulp and paper industry has been facing a severe regulatory risk in its operations.

“World Wide Fund (WWF) carried out clean technology assessments in pulp and paper industries in Kashipur, Uttarakhand. The objective was to suggest clean technologies in the sector. Complete production steps were mapped and major water and chemical consumption processes were identified. The focus was on mapping the production processes and finding major source of pollution load in throughout processes. Also, a techno-economical feasibility study of various technologies was conducted using collected data and literature review to come up with clean technologies for pulp and paper industry.

“Businesses first need to understand the overall scope and scale of their risk as a baseline before starting their water stewardship journey. A starting point for water-risk mitigation for businesses is building an understanding of their exposure to water risks. The Water Risk Filter, developed by WWF in partnership with the German Development Finance institution, DEG, is a practical online tool that not only helps users access and map water risks, but also provides concrete steps to mitigate them. Water stewardship is a ‘journey’ that helps businesses to minimize their impact on water and engage and collaborate with other consumers to reduce their collective impacts. It helps strengthen the way in which river basin resources are managed. WWF is engaging businesses from across the sectors and geographies to embark on water stewardship journeys. Besides helping businesses understand water risks and develop water stewardship initiatives, WWF can provide industries with vital linkages to local communities, NGOs and governments and access to international case studies and best practices.”

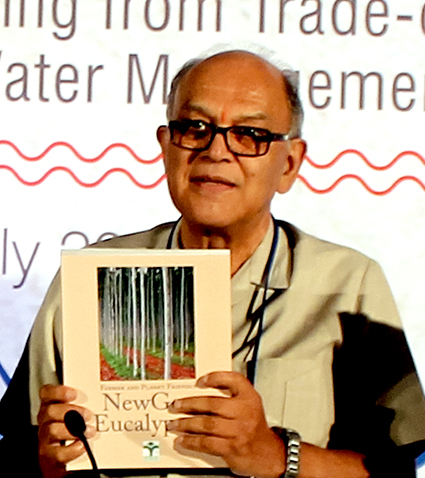

Book Release

During the conference, a book titled “Farmer and Planet Friendly – NewGen Eucalyptus” was released by Chief Guest Jigmet Takpa, Joint Secretary, Ministry of Environment, Forest and Climate Change. This book is regarded as one of the most comprehensive pieces of research done on eucalyptus plantation in the country. It has busted many myths related to eucalyptus. Sudhir Pande, Former Director General of Forests, Ministry of Environment & Forests, who wrote the foreword to this book, said that the book could act as guiding light in the government’s forestry policy formulation.

During the conference, a book titled “Farmer and Planet Friendly – NewGen Eucalyptus” was released by Chief Guest Jigmet Takpa, Joint Secretary, Ministry of Environment, Forest and Climate Change. This book is regarded as one of the most comprehensive pieces of research done on eucalyptus plantation in the country. It has busted many myths related to eucalyptus. Sudhir Pande, Former Director General of Forests, Ministry of Environment & Forests, who wrote the foreword to this book, said that the book could act as guiding light in the government’s forestry policy formulation.

Chief Guest’s Address

Speaking at the conference, Jigmet Takpa said, “India constitutes only 2.4 percent of world’s geographical surface area and sustains the needs of 17 percent of human and 20 percent livestock population. We get only 1 percent of global rain and have 4 percent of the water resources of the world. As a result, there is too much pressure on the country’s natural resources. Every natural resource in India is over stressed. The impact of climate change on these natural resources has been rather alarming. This year, the month of June was the fifth driest period in the entire century. The four of the warmest years ever recorded were the last four years, and the current year ended up being the warmest year. June 2019 was drier than normal across the nation. A drought has developed and intensified in most parts of the country. It will further add to the already warm temperatures.

“The Government of India has come up with various programmes and projects. It introduced Jal Shakti Abhiyan – a campaign for water conservation and water security. Jal Shakti is a collaborative effort of various ministries of the Government of India and state governments, being coordinated by the Department of Drinking Water and Sanitation. The focus of the campaign is on water-stressed districts and blocks.

“Water and land are referred to as the two sides of a coin; one affects the other. If there is land degradation, it is caused due to lack of water. So, if we need to combat drought, we have to adopt measures to make land productive, which in turn will conserve more water. Integrated land and water management is a key method for the prevention of desertification. In India, land degradation—broadly defined as loss of productivity—is estimated at 96 million hectares, being under dry land, and nearly 30 percent of the land is under desertification. Desertification is a form of land degradation by which fertile land becomes desert. More than a quarter of India’s land is turning into desert, and the rate of degradation of agricultural areas is increasing. The United Nations Convention to Combat Desertification is responsible for combating desertification and mitigating the effects of drought through national action programs.

“The monsoon in India is limited to two to three months of the whole year, and rain distribution is uneven. This results in drought in some regions and floods in other parts of the country. The question is how are we managing and conserving excess rain water, which usually drains away in sewage and becomes waste? We need to be very specific about our policies and measures to converse rain water.

The Government of India has come up with various programmes and projects. It introduced Jal Shakti Abhiyan – a campaign for water conservation and water security.

“The agriculture sector is one of the biggest users of the water. Out of the total amount of groundwater available in the country, around 85 percent is utilized in farming, while 25 percent is left for drinking, sanitation and industrial use. Ironically, the industrial sector has been the biggest victim when it comes to water usage in India. The government has implemented a centrally sponsored scheme for micro irrigation to enhance water-use efficiency in the agriculture sector. Under the scheme, technological interventions like drip and sprinkler irrigation systems are promoted to encourage farmers to use them for conservation and saving of water and improved yield. However, it has been reported that the agriculture sector has been using deep irrigation. The practice of deep irrigation inundates the land, and in the process, the land gets saline and water-logged causing weak productivity.

“It has been reported that productivity per hectare in India is the lowest in the world. India produces 1 tonne per hectare, while the rest of the world produces 6 tonnes per hectare. So, if we take care of land productivity, we can increase the income of the farmers six times. However, in India efforts are made more towards expanding the agricultural sector than towards increasing land productivity. Our country is ranked topmost in the world when it comes to net agriculture land. We have 51 percent of our land under agriculture, while the other countries have only 10 to 15 percent. This indicates how much land in India is stressed and overused causing low productivity, and the availability of groundwater has gone down. The availability of water in the future is predicted to be bleak if proper steps are not taken now to deal with the management of the available water resources in the country. In recent years, rural development departments have looked towards watershed projects as a way to realize their hopes for agricultural development in rain-fed, semi-arid areas.

“Under Jal Shakti Abhiyan, officers from the central government will visit and work with the district administration in 1,592 water-stressed blocks in 256 districts to ensure steps are being taken for water conservation and security. Such initiatives and programmes by the government can be regarded as a big step towards positive change and a brighter future. The pulp and paper industry has successfully adopted new technologies for the efficient use of water and recycle with zero water discharge. However, some industries are still engaged in discharging untreated sewage into canals and the ground. Industries must use water judiciously and do their best to become sustainable and efficient.”

The First Session

The first session of the conference saw experts making informative presentations on water management in India. The speakers focussed on subjects such as development of indigenous technologies, emerging reforms and policies, best practices on water and wastewater management in the pulp and paper sector, tools and techniques for water reuse and recycling, integration of technology providers with technology users and issues and challenges on groundwater abstraction guidelines.

The Second Session

The second session was devoted to “select practices on efficient management of water and wastewater systems.” Eminent personalities in the pulp and paper industry in India presented relevant case studies and papers on the subject.

The conference ended with a master class on intelligent technology solutions for water and wastewater management. Rakesh Kumar Jain’s presentation on membrane filtration, an emerging technology for wastewater management in the Indian paper industry, was well received by the audience.