Intelligent integrated deckle matching software is optimal for paper mills as it provides end-to-end support through the integration of the CRM and Production Management System. Kaiznn™ by Haber is a one-of-a-kind, intelligent, and integrated deckle matching software enabling mills to make quicker decisions to optimize their resources.

“Deckle optimization in most cases entails spending time and workforce in data collection and analysis… With Kaiznn™, even while stacking up new orders, the deckle matching solution is recalculated to provide multiple options, in a matter of minutes.”

In an interview with Paper Mart, Ms. Tejaswani, Product Manager, Haber, discusses Kaiznn™, Haber’s latest product that has been specifically curated towards the pulp & paper industry. She explains how the Software-as-a-Service (SaaS) product by Haber brings forth the benefits of an integrated software system to hone deckle matching services at paper mills.

Paper Mart: To start with, could you please describe the deckle matching process at Haber?

Tejaswani: Deckle Matching is a complex process involving devising a solution that achieves maximum production efficiency, minimum trim loss, and quick turnover of orders. The calculations are complex, with multiple variables being considered and real-time dynamic changes being involved. Based on the current market and production capabilities, there is also a need to ensure that the solution achieves the best-case scenario for efficiency, trim loss, and turnover.

Our product Kaiznn™ provides the upgrade for the same as it is a first-of-its-kind Deckle Management system with an integrated CRM and Production Management system.

PM: Kindly shed some light on Kaiznn™ and its key features.

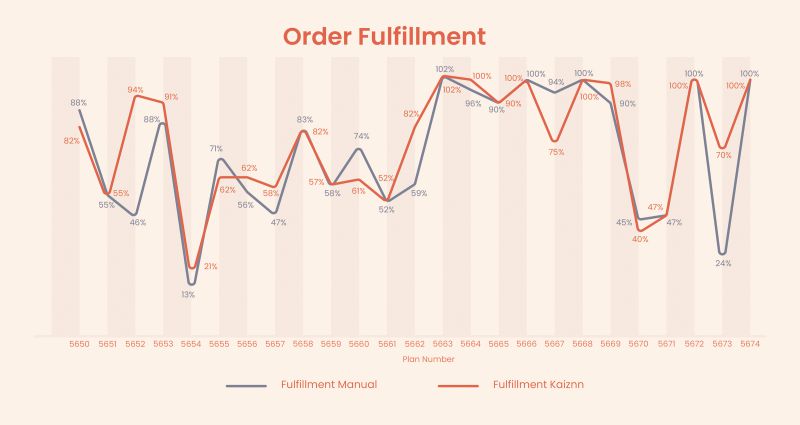

T: With Kaiznn™, paper mills can maximize order fulfillment and ensure reduced trim losses. It supports meeting all delivery commitments, maximizes profits, and achieves deckle planning with the best possible outcomes in seconds, helping the mills provide quality customer satisfaction. It also shows real-time information on order and production stages, enabling quick decision-making with actionable insights.

Watch: IVAX Paper Chemicals Interview

PM: How does the software work?

T: Based on the orders in the pipeline, different job combinations are explored in real-time. The job combinations are compiled for variably sized & weighted orders of a particular GSM range where once the set of orders is finalized by the user, Kaiznn™ checks all the order line items based on the specifications provided and gives multiple solutions for it, considering criteria such as trim loss optimization, order fulfillment, and delivery window.

Kaiznn™ also allows you to experiment with solutions by including stocks, changing the deckle, and cutters, amongst other parameters, to curate solutions according to one’s mills’ needs.

PM: You mentioned that Kaiznn™ also maximizes order fulfillment. In what way does it do so?

T: Deckle optimization in most cases entails spending time and workforce in data collection and analysis by the users, thus resulting in lesser resources being allocated towards decision making. With Kaiznn™, even while stacking up new orders, the deckle matching solution is recalculated to provide multiple options, in a matter of minutes. In fact, through Kaiznn™, one of our customers was able to increase their order fulfillment capabilities from 69.92 percent to 75.32 percent, while reducing the period to land on the final solution, from order entry to the result formulation, which took a mere 30 minutes.

Also Read: Haber: At the Forefront of AI-driven Water Treatment

PM: How does it help in bringing down production costs?

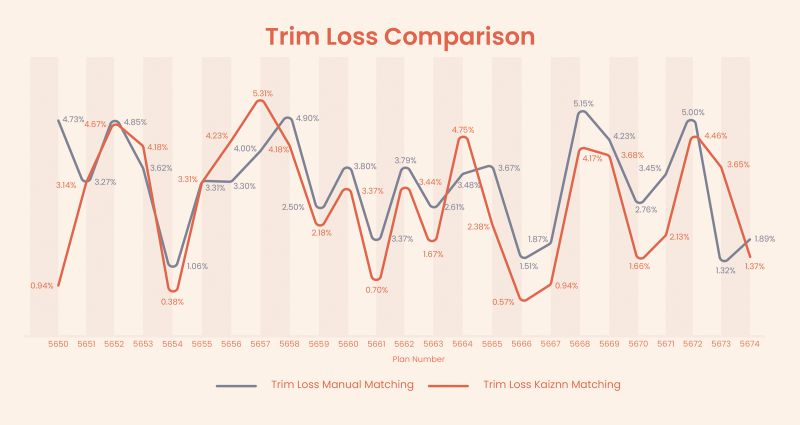

T: As the algorithm works towards recommending the best combination of orders, it ensures that most of the material is utilized, and profit is maximized. Its implementation ensures that trim loss can be managed significantly. This is because deckle matching through Kaiznn™ unlike manual matching provides trim loss information as well during solution iteration, which helps the user estimate the trim loss reduction while iterating the solutions themselves. In fact, the same manufacturer also observed a 12.30 percent reduction in average monthly trim loss to reach sub-3 percent levels by using Kaiznn™.

Overall, this resulted in the customer registering 5.45 percent of savings in their inventory.