The wood based paper mills in India have been facing the serious challenge with regard to availability of forest-based raw material. The continuous increase in the pulpwood price is making the fire more furious. This situation demanded that the respective companies should try to materialize on the resources available to them and go for thorough R&D to tackle the dearth of raw material. One such example is ITC’s efforts for meeting wood requirement for its pulp and paper production. Here we present a case study explored with Mr. HD Kulkarni, VP (Plantation) at ITC Ltd (PSPD), Unit: Bhadrachalam, on how ITC developed agro farm forestry as a solution to address this challenge.

Paper and paperboard has become an essential requirement of our life. The current global paper and paperboard demand is 402 MTPA. The forecast for paper production by 2021 is projected at 521 MTPA. In India the present consumption of paper and paperboard including newsprint is at 11.15 MTPA (per capita consumption at 9.3 kgs) and the growth of paper mills from 17 units in 1950 to 759 in 2010 with a production of 10.11 MTPA is spectacular. With the GDP growth expected to be at 8% for the five year plan period 2013-17, growth in consumption of paper and paperboard is expected to be about 8%. This translates in to consumption of about 24 million tons and production of 22 million tons by 2025 resulting in per capita consumption of 17 kg. All this means rapid growth of pulp and paper industry in India that ultimately requires wood as raw material.

The wood based paper mills in India continue to face challenges with forest-based raw material. Pulp and paper industry consumes 3% of total national requirement of wood while, the major consumption being fuel wood (89.5%) and timber (7.5%). The wood and bamboo based mills contribute 31% production which is 3.19 million tons and there are 26 large integrated paper mills. The annual pulp production is 3.03 million tons from 10 million tons of wood plus agro-residue and waste paper fiber. Nearly 20% of wood is procured from government sources while, 80% is from agro farm forestry sources. The bamboo and wood requirement is 0.82 and 9.27 MTPA respectively.

Under the forest policy, acts and rules the supply of raw material to wood based industries is phased out from forest areas. Participation of the private sector, even in reforestation of 28.84 million ha degraded forestlands and joint forest management is not allowed as per the policy guidelines of government of India. Over a period of 23 years, paper industry has promoted nearly 650,000 hectare of plantation, which is estimated to produce 39.42 MTPA of wood at 60 tons/ha yield. However, if we consider last 5 years plantations of eucalyptus, casuarina, leucaena and acacia, it is 300,000 ha which can produce 18 million tons of wood. At the felling cycle of 4 years, the wood production annually is 4.5 mn tons. The current level of planting by the paper mills is around 50,000 ha/yr. Apart from the industrial efforts, farmers on their own are raising plantations adding to the general availability of wood to the industry. Hence, the industries wood demand of 10 million tons annually is somehow met through farm forestry plantations.

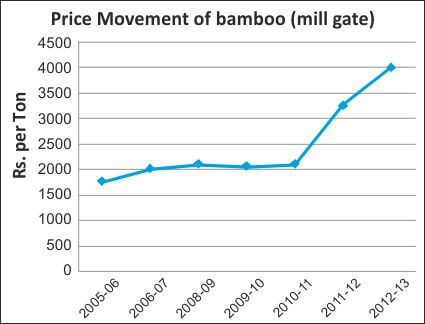

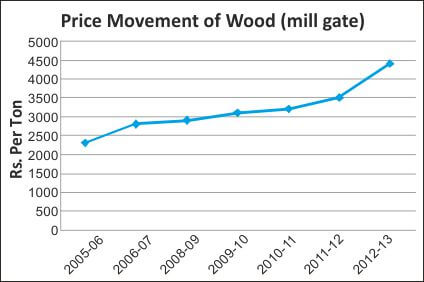

There is drastic increase in pulpwood prices from 40 to 84 USD/ton and availability is dwindling.

Considering the future demand of paper by 2025, an additional 12 million tons of wood is required from 1.2 million ha of pulpwood plantations and 0.36 million ha (30% extra) for fuel, fodder and local usage. The total land mass therefore required to raise pulpwood plantation will be around 1.56 (say 2) million ha with an assumption of 50 tons/ha productivity for a felling cycle of 5 years.

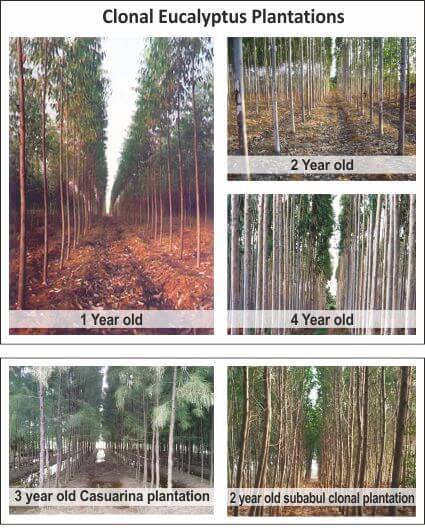

ITC (PSPD), Unit: Bhadrachalam, produces 300,000 tons of pulp with 11,25,000 tons of wood. To meet the wood requirement, the company embarked on an ambitious farm forestry project. The tree improvement research on eucalyptus, casuarina and leucaena was launched in 1989. Selection and breeding along with root trainer technology was employed for improving the productivity and profitability of plantations. The survival percentage of clonal plantation was more than 95 compared to 40 to 60% and productivity of 20 to 58 t/ha/yr compared to 6 to 10 t/ha/yr from seedling origin plantations. Site specific and disease resistant clones, 107 of eucalyptus, 12 of subabul and 15 of casuarina were developed, multiplied and given to growers for raising plantations.

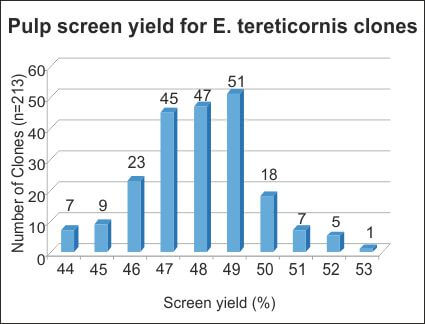

Wood morphological studies were conducted on 225 clones and high pulp yielding clones with desired density and fiber morphology were shortlisted.

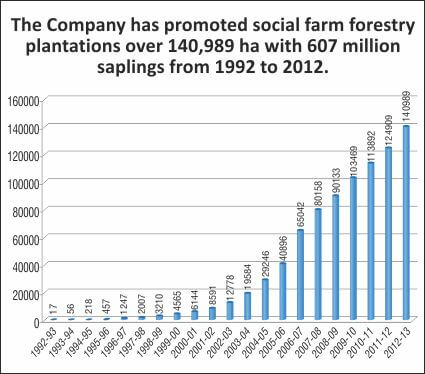

It is estimated that, plantation of 140,989 ha over a period of 33 years (1992 to 2025) give an estimated wood asset value of USD 2,727 million (Rs. 13,637 crores) at an average farm gate price of Rs. 2,500 per ton (price range from Rs. 700 in 1992 to Rs. 3,000 in 2012 and likely to be Rs. 4,500 by 2025). Provide an estimated 63 million person days of employment from tasks such as nursery, planting, logging and maintenance etc operations. An estimated potential to sequester 93.28 million tons of carbon by reducing 171 million tons of CO2 over a period of 33 years. On an average the annual CO2 reduction works out to 5.18 million tons. ITC therefore is a carbon positive company. Thus, ITC plantations are playing an increasingly important role in rural economic development and poverty alleviation creating enduring value on economic, societal and environmental bottom line.

As the paper consumption is going to increase to 24 million tons by 2025, which requires planting of 2 million ha to obtain 12 million tons of wood. Clonal plantations covering 2 million ha of the degraded forest areas if taken up can yield 25 million tons of pulpwood annually. That would be sufficient for meeting India’s entire pulp and paper requirements. Likewise, high yielding short rotation clonal plantations on 20 million ha of wastelands/degraded forestlands could meet country’s current firewood requirements on a sustainable basis. That would minimize biotic pressures on remaining natural forests and conserve their rich bio-diversity. In addition to restoring marginal lands to high sustainable productivity, clonal plantations will generate vast employment opportunities for the rural poor, contribute to environmental amelioration and help conservation of precious soil and water resources. Such plantations will also create opportunities for significant value addition through local processing of plantation wood and save large amounts of scarce foreign exchange used to import of wood based products. Therefore, clonal fast wood forestry can bring “Brown revolution” in India.