The Indian corrugated market at the moment is stable and poised for a very strong growth in the next several years, particularly, with the rise in food packaging and e-commerce packaging.

Riyo Parapack Pvt. Ltd. is a Mumbai-based packaging company offering a wide range of corrugated packaging solutions under a number of sub-brands. The company has recently introduced a B2C-based platform offering a range of packaging solutions for small businesses & individuals. Further, the corrugated packaging provider is going to undertake a Greenfield expansion project which is scheduled to be completed at the end of 2022.

Paper Mart interviewed Mr. Rishabh Agarwal, Director, Riyo Parapack Pvt. Ltd. wherein he shares an overview of the company, their manufacturing capabilities, the key expectations from the paper mills, the current challenges facing the corrugated industry, and their plans for the future.

Paper Mart: Tell us about your company, the manufacturing capabilities, monthly paper converting capacity, and the key in-house technologies.

Rishabh Agarwal: Riyo Parapack is a family-owned enterprise established in 1996-97. We began our journey with two semi-automatic machines in Daman. This year marks the 25th anniversary of the company which is a significant milestone for us.

In 2007, we set up a fully automatic 5-ply board line purchased from JS Machines in China at our facility in Vapi, Gujarat; and we gradually discontinued our operations in Daman. In 2010, we set up a second line in the Vapi factory. For a long time, we were one of the few packaging companies in India to have two automatic production lines under one roof.

Our unit is equipped with enormous capabilities. We also have different types of automated converting machines. At present, we have four inline flexo printer die-cutters, and we are presently converting about 1,500 tonnes of paper per shift.

PM: What challenges do you face with regard to the quality of paper and paperboards?

RA: While there are a few good paper mills that are exceptionally sincere and diligent in their pursuit of quality, the rest of the paper mills are not quality-oriented. In fact, owing to the fragmented market situation, they have not been under any pressure to produce quality products. This has been a persistent concern in the entire value chain of the industry, starting from paper leading up to the corrugated boxes.

As it is said that “Necessity is the mother of invention”, there are competent solutions to cater to the needs of the customers looking for high-quality products. Nevertheless, the market is so diversified that on one hand, there are customers who are looking for excellent quality, and on the other, there are customers who are fine with substandard products. This creates a huge difference.

The second major concern is that the waste management system and the recycling system are inadequate in India. The improper collection of waste paper and the challenges in waste segregation have a definitive impact on the waste paper-based mills in the country. As a result, the availability of short and long fibers required for producing quality paper is a major concern for the paper industry. The Indian waste paper-based mills have to rely on imported waste paper for their raw material needs. This practice is likely to continue as there is no choice available. Also, with the growth in the paper-based packaging industry, the demand for paper will grow and since we have a fiber shortage, we will have to continue depending upon the imports of waste paper.

Talking about the brighter side of the industry, in the last few years, several Indian paper mills have substantially upgraded their manufacturing units. Many new mills have introduced advanced technology resulting in more export opportunities. However, we still have a long way to go.

‘’While there are a few good paper mills that are exceptionally sincere and diligent in their pursuit of quality, the rest of the paper mills are not quite quality-oriented.”

Watch: Paper Mart News Roundup

PM: What are your major expectations from the paper mills?

RA: A few years ago, the RCT test, which is an important criterion for producing a high-quality corrugated box, was conducted by just a few paper mills in our country. However, the approach of the mills is changing for the better. Now, some of the fundamental standards like consistency, proper standardisation, and other important factors like odour in the paper are being given more attention than before.

Moreover, there was no distinction made between testliner and fluting grade, which is an international norm. These are a few important factors that need to be addressed by the paper mills. However, on the positive side, there are a few paper mills that are taking initiatives and paying close attention to the above-mentioned factors by working closely with the converters. These mills are bound to emerge as winners in the long run and hopefully, other mills will also take a cue from them and become more quality-oriented.

PM: With the emergence of the new normal due to the pandemic, what are the current market scenario and your projections for the future?

RA: The pandemic has not significantly impacted the corrugation industry from the production part — apart from usual issues like lower productivity due to minimum manpower and getting spare parts from overseas. At the same time, it is facing unprecedented challenges from the front of paper prices and a consistent supply chain. In the long term, the Indian corrugated market is poised for strong growth in the next few years, particularly, with the rise in food packaging, e-commerce packaging, etc. Also, the world is looking at India as a very important alternate to China, coupled with the ‘Make in India’ program which is going to prove to promise for the further growth of the corrugated industry.

The raw material availability is going to be a challenge owing to the high dependence on imports for waste paper. This creates a strong need to improve the recycling and waste collection methods in addition to securing the fiber availability from overseas.

The third important factor is adequate skill development for the corrugated industry. Around fifteen years ago, the corrugated packaging was under SSI (small-scale industry), which meant that it could not have large investments. In fact, during that time, Sri Lanka had more automated corrugated plants than India, which has now changed. In the past few years, large investments have been in automation and now, the corrugated box factories have become bigger in scale than earlier.

The Indian government has managed the COVID situation extremely well and a lot of groundwork has been done for any such situation that might arise in the future. Overall, the government has done a superb job in managing the crisis.

In the medium term, the corrugated industry could have a set of challenges pertaining to worldwide disruptions which will have a ripple effect in our journey back to normalcy.

It seems that the turbulent times will continue as we are seeing that every other day, there is some news of another matter affecting the whole society at large. For instance, in the last few days, the situation of Evergrande Group’s crisis in China and the Coal/Power Crisis, these are the issues that might create a spillover effect on the global economy as well.

Corrugated Box users must have to understand that they need to support our industry to help them. In the present scenario, the corrugated industry is passing through a crisis due to paper & supply chain disruptions. It is important for them to understand that we have always delivered but times have changed. A healthy corrugated box industry is essential to them.

‘’The corrugated packaging industry is going to attain strong demand and growth of around 10 percent year-over-year for the next five years.”

PM: Do you have any particular expectations from the future generation – the youth looking to make their career in the packaging industry?

RA: With the huge growth taking place in the packaging industry, we have seen that there has been a rise in the number of people who are looking to make their career in the packaging industry. A few days ago, the government has proposed to declare the Indian Institute of Packaging an institution of national importance in the draft bill. It will enable the institute to develop and conduct courses in an autonomous way for graduate and post-graduate degrees, and post-doctoral courses, and undertake research on international marketing in packaging. This marks a very significant move for the Indian packaging industry. It will open up avenues for more research on product packaging which will lead to the advancement of the packaging industry.

The major concern is that the students should be trained and equipped with the required skills for the factory job. There should be a greater emphasis on the skill development of the young generation and familiarising them with the advanced techniques in the field of packaging that will enable them to become a part of a competent and skilled workforce.

PM: Kindly share your views on the market trends and the demand drivers.

RA: The corrugated packaging industry is going to attain strong demand and growth of around 10 percent year-over-year for the next five years. The major demand in the industry has been driven by the surge in e-commerce, food industry which includes packaged food as well as the packaging for fruits and vegetables. The large multinational companies sourcing in India for the Indian market and the exports as I already said that they would be looking at India as a strong alternative to China.

PM: Please talk about the recent developments, product launches, and expansion plans for the future.

RA: Shedding some light on the recent past, with the outbreak of the pandemic, the first wave of the pandemic did not affect our business operations substantially. However, in the second wave of the pandemic, we did face a few challenges to the degree that we had to press the “reset” button as we had to reorganize, reassess and restrategize our business plans.

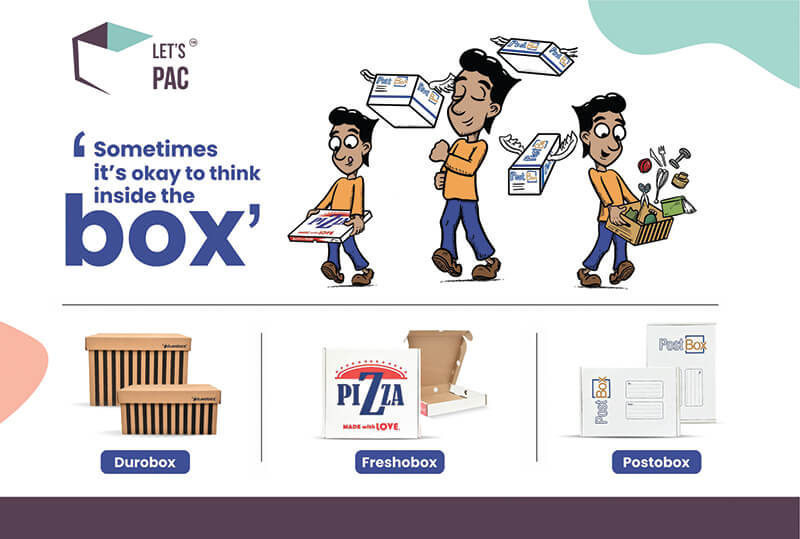

With regard to our new developments, we launched Let’s Pac in 2021 — which is an online platform principally with a unique, first-of-its-kind B2C model for corrugated box users in India. The platform is essentially aimed towards providing solutions for packaging requirements in small businesses and households. For instance, we have packaging solutions for a business that needs to courier a few samples of their products such as garments, shoes, etc. Also, if one wants to store documents in a proper way, we provide different kinds of parcel boxes and storage boxes under our sub-brands Postobox and Durobox respectively.

During the lockdown period, we witnessed a rise in the number of small businesses selling homemade food. We have the ideal packaging solutions for their requirements such as Freshobox which is specifically made for pizza or cake delivery.

With regard to expansion plans — we have planned a new Greenfield project, and already have land adjoining our factory for the same. We will be incorporating a new generation state-of-the-art corrugation line. With this investment, we are planning a capacity to convert around 8,000 tonnes per month. The new Greenfield project is slated to start at the end of the year 2022. At present, we are at the planning stage of the proposed expansion.

Presently, we are focusing on research and development, on maintaining consistency in quality, and on planning for new product development in the future. At the same time, we are aspiring to be a 100 percent renewable energy-based company.

‘’We launched Let’s Pac in 2021 — which is an online platform principally with a unique, first-of-its-kind B2C model for corrugated box users in India.”

Also Read: Evolution of Paper-Based Packaging

PM: Would you like to add anything else to this conversation?

RA: The corrugated industry seeks to attain superior quality products from its suppliers in a consistent manner. I would like to sum up our interaction by saying that the Indian corrugated packaging industry is poised for good growth. Further, the level of quality in the domestic industry is rising to be at par with the global level and the automation in corrugated plants is also steadily increasing.