We are completely committed to coming up with a wide range of products for the pulp and paper industry… reducing the pollution footprint of the industry and also helping the industry to save costs.

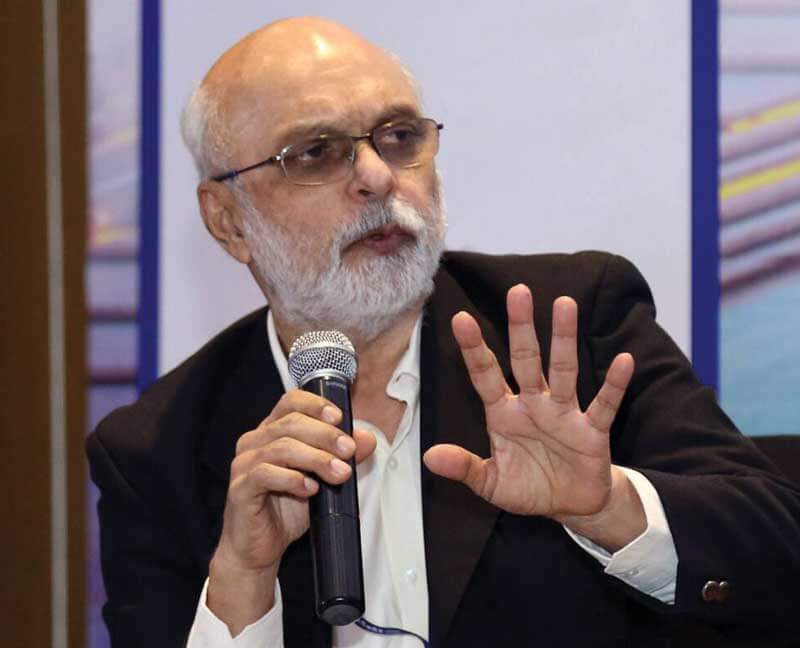

Established in 2012, Proklean Technologies is a company based out of Chennai. It was founded to explore industrial applications using probiotics with the core intent of contributing to making the world a better place by reducing pollution and conserving natural resources. Proklean has developed a proprietary technology using a unique combination of probiotics with fermentation and formulation methods. In an interview with Paper Mart, Dr. Sivaram Pillai, Co-Founder & Director (R&D), Proklean Technologies Pvt. Ltd., talks about his journey, product portfolio, and an outlook on the pulp & paper industry.

Paper Mart: Tell us in brief about Proklean Technologies Pvt. Ltd. and walk us through your journey.

Dr. Sivaram Pillai: Proklean Technologies was started by me and two other friends about ten years ago with the objective of doing something interesting in the area of probiotics since all of us had a common interest in that subject. Within a year or two, we came up with a very unique way of using probiotics to produce non-toxic and biodegradable surfactant formulations, which could replace the chemical surfactants. We started with the leather industry and moved on to the textile industry. Based on our experience in both these sectors, we entered the pulp and paper industry.

We have developed very unique applications in the pulp and paper industry which significantly reduce the use of bleaching chemicals, but at the same time, deliver the parameters required by the customers. We end up saving money for our customers by reducing the usage of basic chemicals like peroxide, chlorine dioxide, and caustic, which also helps us to achieve our original objective of reducing pollution.

We make sure that anything we develop is sustainable both in the manufacturing process as well as the application. Similarly, anything we introduce commercially should lower the cost of processing for the customers, and at the same time, release less pollution. These are the boundaries that we have set in our journey.

We were originally bootstrapped for three-four years, and then took funding from investors, first from a group of angel investors, then, subsequently switched to venture capital funds. Over the last few years, Proklean Technologies has been building a professional team and since April 2021 the day-to-day management of the company is managed by this team.

PM: Please elaborate on the product portfolio and the clientele of the company, specific to the paper industry.

SP: In the pulp & paper segment, we have been able to introduce cooking aids, odour controllers, and bleach enhancers.

We have launched ProCook, which is a first-of-its-kind non-foaming cooking aid solution that is readily bio-degradable and non-toxic. The cooking enhancer enhances the cooking process while cutting down mercaptans by up to 50 percent. Lower levels of mercaptan gases translate into reduced corrosion thereby saving on maintenance. So, we have a product that enhances the cooking process and has significantly better functionality than other cooking aids currently used in the pulp and paper industry.

Talking about our odour control range, ProEnviro is globally the first-of-its-kind formulation developed specifically for the paper industry to control/eliminate odour from the cooking operation by neutralising mercaptans, sulphides and thereby enhance significantly the environment and hygiene in and around a pulp mill.

We have also introduced odour controllers for kraft paper mills. As odour is caused by pathogens, we use good microbes to neutralise and reduce their population. ProSolve+ is a uniform blend of Bio-dispersant along with a consortium of naturally occurring beneficial microorganisms. The exopolysaccharides & other organic acids produced by the probiotic microbes act as a potent biocide thus eliminating biocides and hypo. Within a year, over 25 kraft paper mills have adopted this technology.

Prowhite and Probleach are first-of-its-kind products for application in pulp & paper processing during the delignification and bleaching stage. These proprietary probiotic formulations are readily biodegradable products meant for diverse stages of bleaching.

ProRB is a powerful anti-oxidant with high metal chelating property to inhibit iron from impairing the function of Hydrosulphite while the anti-oxidants enhance the reduction efficiency.

We have recently launched a product for control of stickies which is again giving good results and getting appreciation from the customers. Pitch control is another important application for both bagasse and hardwood-based paper mills and we have launched a few products in this segment that have started giving good results. Slime reduction is another demand for the industry. We have introduced a product which achieves good slime control for the writing & printing segment.

We now have over 35 customers in the pulp and paper industry across bleaching enhancers, deinking, and other products. We serve many large companies as well as medium-scale enterprises including ITC PaperBoards & Specialty Papers Division, Century Pulp and Paper, APL, West Coast Paper Mills, and Tamil Nadu Newsprint and Papers Ltd. (TNPL).

PM: Tell us about your upcoming products. Do you have any products for water treatment as well?

SP: Our R&D team has been working on new products for water treatment based on our core Probiotics platform and one such product that would soon be commercialised is bio-flocculant for reducing the sludge. We are also developing a bio-masking agent, which will not just mask the bad odour, but neutralise the cause of odour in a sustainable way.

We have formed a separate research team now, with experienced people from the pulp and paper industry. We have a senior scientist with a chemistry and biotechnology background. Our goal is to cover the entire spectrum of the pulp and paper industry in terms of process, except the finishing applications.

“Our R&D team has been working on new products for water treatment based on our core Probiotics platform… we are also developing a bio-masking agent, which will not just mask the bad odour, but neutralise the cause of odour in a sustainable way.“

Watch: Evolution of Paper Based Packaging

PM: What are the USPs of Proklean Technologies?

SP: The manufacturing process of our products has a very low carbon footprint as we carry out the fermentation in ambient conditions without any heating or cooling. Usually, the downstream purification process in fermentation-based manufacturing is highly energy-intensive and it releases a lot of effluents. We have completely eliminated the downstream processing, which saves significant energy as well as releases zero pollution. Also, the products are readily biodegradable and non-toxic. Overall, we practice a circular economy by using raw materials which are sourced from nature, using a low carbon footprint manufacturing process to make readily biodegradable products that go back to nature!

Typically, green products are not used that much, because they tend to be more expensive than chemical solutions. In our case, we have been able to match the costs due to an innovative low-cost manufacturing system. Therefore, the customer is willing to try our products, which while being cost-competitive, also provides green benefits.

PM: What is your outlook on the paper industry and your future plans?

SP: As I mentioned, Proklean Technologies is completely committed to coming up with a wide range of products for the pulp and paper industry. We believe that we can contribute significantly both in reducing the pollution footprint of the industry and also helping the industry to save costs.

We have set up a separate section in our R&D lab for paper product development. We will be coming up with more and more products for the industry.

“We make sure that anything we develop is sustainable both in the manufacturing process as well as the application.“

Also Read: Proklean Technologies: Making Pro–Environment Speciality Chemicals

PM: In what ways do your solutions assist the paper industry in addressing the crucial parameters like cost reduction, better quality, and enhanced efficiency?

SP: We have been able to make a mark in the industry in a very short span of time due to two reasons:

The products and solutions Proklean Technologies offer to the consumers help in reducing costs. For example, a large paper industry player purchased our bleach enhancer, and with this, they are able to reduce their process costs by INR 50 per tonne, after paying for the cost of our product. That is a significant cost reduction if we consider the large volume of pulp processed by this mill.

Second, our products enable the customers to reduce their pollution footprint, that is, reduce the pollution load/COD load, which helps the industry to further reduce the costs of processing.

For instance, for a large mill proposing to invest a significant amount of capital in treating their effluents, if their effluent load is reduced, the effluent treatment costs also come down.

Overall, our products save costs and deliver excellent results. We do not compromise on results as far as the customer is concerned.