The web width can be customised as per specific customer requirements. The EdgeSaver by Voith ensures a significant reduction of raw material costs along with a smaller carbon footprint.

February 24, 2022

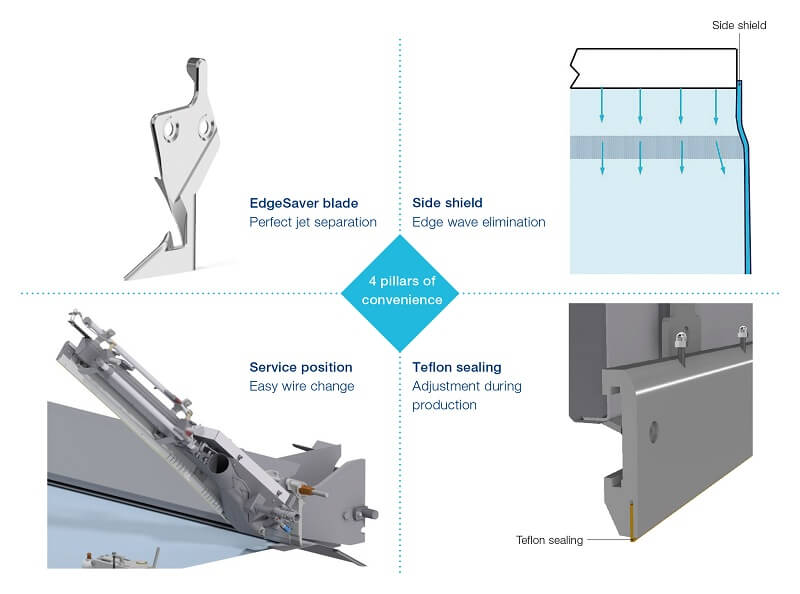

Voith has introduced EdgeSaver, a new edge trim concept, to effectively enhance the range of products for stabilising the web edge in the headbox area. The innovative edge trim system trims the web edge in the stock jet exiting the headbox. Thus, it enables the paper manufacturers to save not only valuable raw materials such as virgin fibers but also reduce the energy consumption for paper production.

Watch: Evolution of Paper-Based Packaging

The innovative design of the EdgeSaver blade brings a simple and energy-efficient solution for adjusting the web edge directly in the headbox jet. Since the fibers are discharged before the suspension reaches the wire, the fibers with a width more than the required paper web width are not lost in the couch pit. In addition, the web width can be customised as per specific customer requirements in the wet-end. Therefore, with EdgeSaver, there will be a significant reduction of raw material costs along with a smaller carbon footprint.

Oliver Kern, Plant Manager at Papier- und Kartonfabrik Varel, says, “By using the Voith EdgeSaver we consume less energy and therefore reduce our carbon footprint because the product allows high-quality fibers to be retained. This means, we not only produce more sustainably but also more cost-efficiently.”

With EdgeSaver, the paper quality can also be significantly improved. Due to the specially manufactured side shield with a patented, adjustable S-shape, edge waves are minimized which also enhances the edge stability.

The EdgeSaver can be fixed to the standard headboxes of all manufacturers and it can be easily installed on both sides of the web in just a few hours during the shutdown. In addition, changing the forming fabric also does not pose a challenge. The ingenious swivel device allows the forming fabric to be replaced seamlessly without having to restore the optimised settings on the EdgeSaver afterwards.

Also Read: Voith Paper Appoints Dr. Michael Weiss as its new CTO

Andreas Jaeger, Plant Manager at MM Neuss GmbH, says, “The EdgeSaver enables us to variably adjust the paper web width without major rebuild measures. Even with changing production parameters, we are able to produce without restrictions, thus reducing breaks and production losses due to defects in the edge area.”