As the Indian paper industry and the whole of the economy at large, is continuing to deal with the effects of COVID-19 on their businesses, factors like – resiliency and agility became essential to sustain growth. The report on ‘Top Paper Companies 2021’ highlights the companies that possess differentiating capabilities and are using their existing and emerging strength making them a dynamic player in the ever-evolving and growing pulp & paper industry.

The pulp & paper industry is quite diversified, using different types of raw materials to produce different kinds of pulp, papers, and paper-based packaging grades, and so on, by various kinds of methods in mills of all sizes. As per the data by Central Pulp & Paper Research Institute (CPPRI), in 2019-20, there are 861 paper mills with 526 operational and with a total installed capacity of 27.15 million tonnes in India. While this is an old research data, owing to the fragmented structure of the Indian Paper Industry comprising of small scale mills operating in an unorganised way, the actual production and the number of mills could be more.

According to an industry research report by Research and Markets, the Indian paper & paper products market is projected to grow from USD 8.6 billion in 2018 to USD 13.4 billion by 2024, with a CAGR of 7.8 percent during 2019-2024.

As numerous businesses in the paper industry were severely impacted because of the lockdown due to COVID-19, it correspondingly brought a huge demand compression in the domestic industry and consumption of paper and paper-based products, especially during the first wave of the pandemic. While the various segments of the paper industry have been impacted but being diverse in nature, it is but evident that different segments have been affected differently. According to the Indian Paper Manufacturers Association (IPMA), the market size of the Indian paper and paperboard market stood at 16.1 million tonnes in 2019. Moreover, the packaging consumption in India increased by 200 percent from the previous year, rising from 4.3 kg per person per annum (pppa) to 8.6 kg pppa.

What sets the top paper companies apart?

Firstly, there are quantifiable factors that play a key role in determining the growth of the paper industry like – production volumes, turnover, and so on. Then, there are a few socio-economic factors impacting raw material availability and supply chain. Finally, the factors like the efforts of the companies in being mindful of their environmental impact and CSR activities also have far-reaching effects on the overall growth and evolution of the paper industry, besides innovations, market trends, and technological advancements.

Steering forward

The paper industry is wood-positive, meaning that it grows more trees than it harvests – has brought around 1.2 million hectares of land under plantations annually, through industry-driven agro/farm forestry. Notably, the domestic paper industry players have suggested some key measures to the government in the past few months in a bid to increase its efforts for becoming more sustainable.

With the aim to enable the paper industry on a path to being self-reliant and resolving the raw material issues, IPMA in its pre-budget consultation with the Ministry of Finance, Government of India, has recommended pulpwood plantations on degraded lands and on available lands near paper mills.

Digital transformations

During the pandemic, a great many pulp and paper manufacturers increased their focus on product and process innovations and adapted in the changed conditions so as to handle such disruptions. In the future, we would witness some of the outputs of these efforts with innovative products getting launched and industry players exploring different models to bolster supply chain management capabilities. Thus, the companies are working towards investing in R&D, building new capacities, new products, and bringing technologically superior and cost-effective products designed for the Indian market.

In the new wave of digital transformation, the pandemic has been like a catalyst for companies across sectors, including the pulp and paper industry, to fast-track adoption of digital technologies to sustain their business in the new normal. In fact, the Writing & Printing segment has been massively impacted by the pandemic. Nevertheless, the paper packaging segment including – paperboards, folded cartons, kraft paper, and so on, has attained good traction, owing to the awareness amongst the general public and as the corporates/FMCGs/restaurant chains are transitioning towards paper-based packaging.

Overall, the Indian pulp & paper industry is moving from being an unorganised and technologically obsolete segment towards being an organised one with state-of-the-art technologies. We believe that the growth in the coming years would be led by new product introduction, strong demand in the paper and paper packaging industry, and an increase in the demand for recyclable, paper-based products, while the macro-theme would be sustainability.

Presenting the Competitive Environment of the Pulp & Paper Industry

Paper Mart’s Top Paper Companies in India is a biennial report featuring the key pulp & paper manufacturing companies of India. This is the seventh in the series of Top Paper Companies – a comprehensive and detailed report based on various key parameters including – production, turnover, net profit, growth rate (in both turnover and net profit), and net worth. In order to incorporate nearly all facets of the companies, features like CSR efforts, water and energy consumption, exports, etc., are included to present all-round and qualitative development of the featured companies. A combined score has been used keeping into account the said metrics equally, presenting a valid and well-grounded assessment. Every two years, Paper Mart presents a list of leading companies — and not just for their financial performance, but also on how these companies score on key activities – their responsibility towards the environment, and society (ESG), and brings out new innovations.

This year’s report by Paper Mart magazine is an in-depth analysis of the country’s most prominent paper companies – known for their relentless pursuit towards maintaining top-grade quality, innovation, and are expanding their reach globally. These are the most eminent industry names who are, by their ideas and innovative thinking, are at the forefront of the new story of the Indian paper industry, which is gradually evolving.

The Indian paper industry has gone through one of its toughest phases with the advent of COVID-19. However, being diverse in nature; different mills have been affected differently. While Writing & Printing and Newsprint segments were most adversely hit, Packaging Grades were able to sail through.

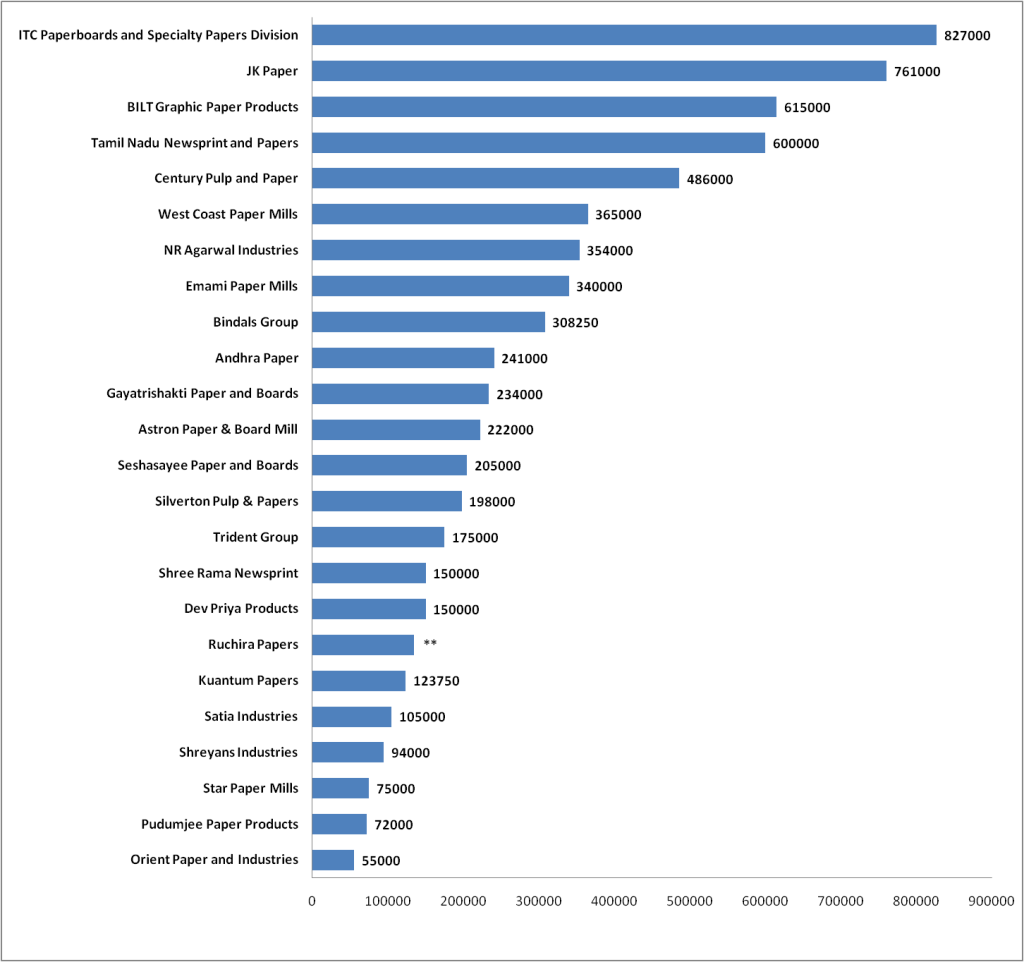

Production Capacity (TPA)

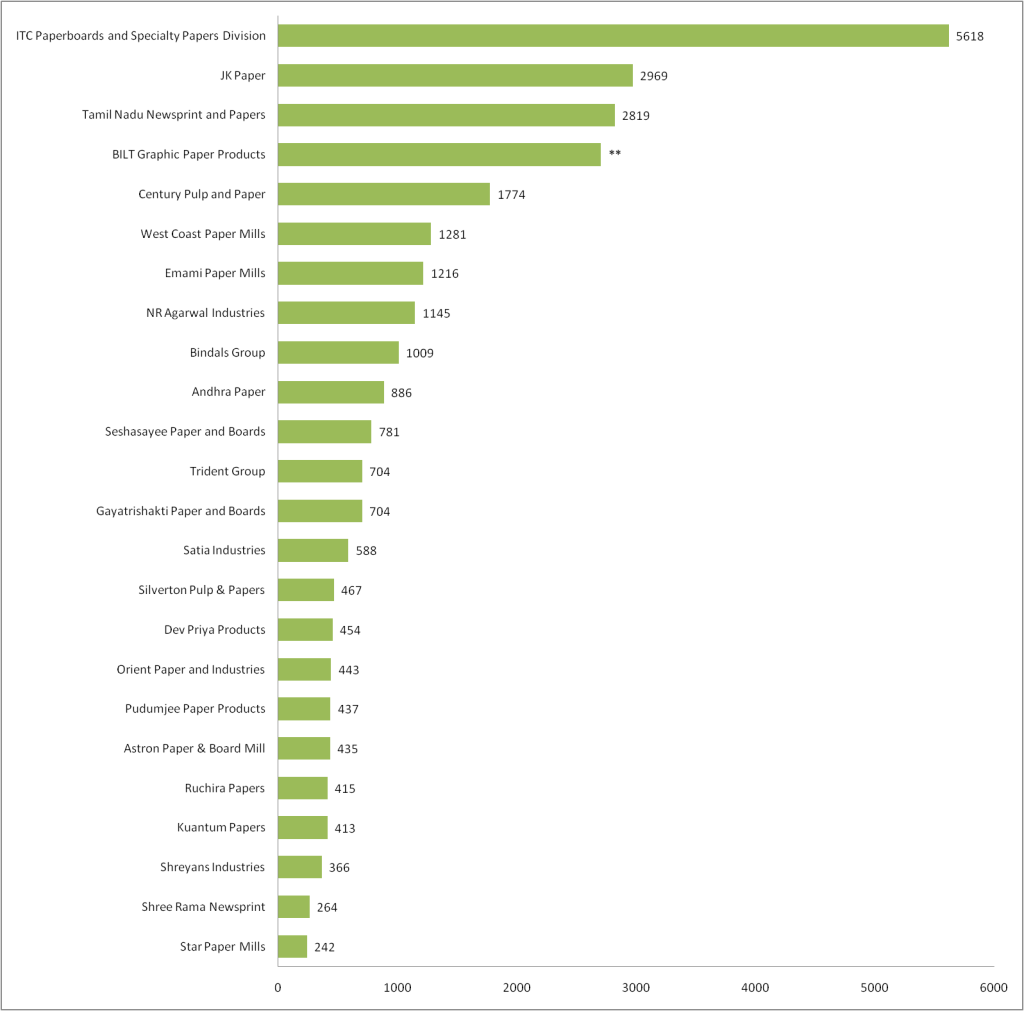

Turnover (in crores)

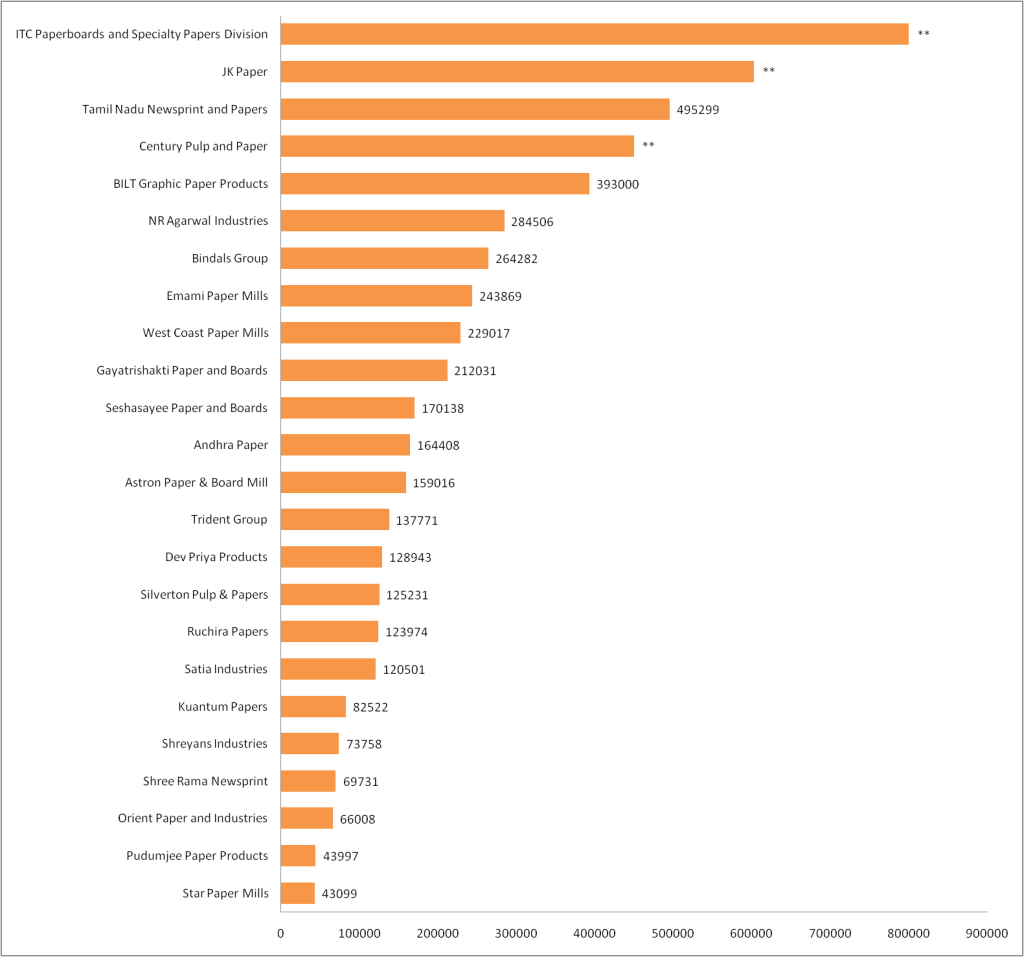

Actual Production (TPA)

The data was calculated either on the basis of inputs given by the companies, or from the Annual Report that was available on the public domain. Our aim in doing this feature was not simply to tabulate the companies but present a broader view of the industry.

* Bindals Group has given the data of the group companies (Bindals Papers Mills Ltd., Tehri Pulp and Paper Ltd., Agarwal Duplex Board Mills Ltd.) as a whole and not of an individual company.

** Some of the values are missing as the company wants to keep it confidential.

*** JK Paper Ltd.’s current capacity has been considered for this survey.

**** Orient Paper and Industries has shared the production capacity of only tissue paper segment.

ACCOMPLISHMENTS

CENTURY PULP AND PAPER

Installed a new tissue plant to manufacture Prime Grade Tissue Paper with a capacity of 100 TPD.

EMAMI PAPER MILLS

Exported around 60000 MT of Packaging Boards to different countries during FY2020-21.

JK PAPER

Installed New Multilayer Board Machine with an annual capacity of 170000 TPA in Unit CPM.

BILT GRAPHIC PAPER PRODUCTS

Received TERI CSR Award, Golden Peacock Global CSR Award and Asian CSR Award for its community initiatives and natural resource management.

GAYATRISHAKTI PAPER & BOARDS

Achieved 31% of export from total production.

ITC PAPERBOARDS AND SPECIALTY PAPERS DIVISION

Unit Bhadrachalam augmented its VAP capacity by 45000 TPA which further strengthens its market standing.

KUANTUM PAPERS

Upgradation and backward integration project helped to increase production capacity from 375 TPD to 450 TPD.

ORIENT PAPER AND INDUSTRIES

Installation of New Energy Efficient Evaporator Street & Recovery Boiler which is under progress stage for INR 185 crore project cost.

PUDUMJEE PAPER PRODUCTS

Upgraded ETP with Artificial Intelligence (AI) controlled system to meet disposal norms of pollution control board.

SATIA INDUSTRIES

Capacity of CRP plant increased from 400 to 650 TPD.

ORIENT PAPER AND INDUSTRIES

Embarked on a Mill Development Plan-III at Unit Erode at a cost of INR 315 crore.

SHREYANS INDUSTRIES

Installed New Bleach Washers and Bio-Mass Based Steam Turbine.

STAR PAPER MILLS

Launched New Products – Star Esquire, Star Esquire Plus, Star Hercules, Star Parchment Buff, Blue Wove, MG Poster (Thermal) and Star Atlas/White.

TAMIL NADU NEWSPRINT AND PAPERS

Launched Aura Green Supreme – a Cupstock variety for hot and cold beverages with superior printability.

TRIDENT GROUP

Launched bleached kraft paper, unbleached kraft paper, sublimation paper and ant-bacterial and eco-friendly notebooks under the name My Choice.

ITC Paperboards and Specialty Papers Division

Enduring Value

| Year of Establishment: | 1979 |

| Locations | |

| Divisional Headquarter: | Secunderabad, Telangana |

| Regional Offices: | Chennai, Mumbai, Delhi, Kolkata |

| Branches: | Ahmedabad, Bengaluru, Chandigarh |

| Mill 1: Mill 2: Mill 3: Mill 4: | Unit Bollaram – Medak, Telangana Unit Bhadrachalam – Sarapaka, Telangana Unit Kovai, Thekkampatty, Tamil Nadu Unit Tribeni, Hoogly, West Bengal |

| Number of Employees: | 3061 (as on 31st March, 2021) |

| Production Capacity: | Unit Bhadrachalam: 6,77,000 TPA Unit Tribeni: 50,000 TPA Unit Kovai: 1,00,000 TPA |

| Financial Information | |

| a) Turnover: | 2020-21: INR 5618.6 crore 2019-20: INR 6107.2 crore |

| b) EBITDA: | 2020-21: INR 1458.5 crore 2019-20: INR 1662.8 crore |

| c) Net Worth: | 2020-21: INR 6164.3 crore 2019-20: INR 6059.1 crore |

| CSR Activities: |

In addition to the regular Social Investments Programme (SIP) of the Company, in these extraordinary times of COVID-19, the immediate and most pressing need was to provide assistance and relief to the poor and vulnerable in the short term and assist in their economic rehabilitation over the medium term. ITC along with ITC Education and Health Care Trust and ITC Rural Development Trust had set up a COVID Contingency Fund of INR 215 crores to help the victims of the COVID-19 pandemic. A large part of the Fund has been utilised towards providing relief to the poor and vulnerable sections of society who are facing severe disruptions to their livelihoods. Additionally, ITC along with ITC Education and Health Care Trust and ITC Rural Development Trust took the following initiatives and contributed towards PM Cares Fund.

- Provided financial assistance to states which have witnessed the worst outbreak of the pandemic and are engaged in minimising its spread

- Provided funds with the aim of (a) distributing hampers containing essential food products and personal hygiene products amongst beneficiaries in identified geographies across India; (b) providing assistance to appropriate entities engaged in combating and controlling the spread of the COVID-19 pandemic; and (c) contributions to identified civil society organisations engaged in providing relief to the poor and vulnerable groups suffering economic privations brought upon by the COVID-19 pandemic

With the onset of second wave of the pandemic, the Company continues its unwavering commitment in supporting the fight against the pandemic and has undertaken several initiatives including:

- Import of 24 cryogenic containers of 20 tonnes each in collaboration with Linde India Limited to ease the bottlenecks in transporting oxygen

- Supply of oxygen to identified Government hospitals in the state of Telangana from Paperboards unit in Bhadrachalam

- Setting up of 3 facilities with 600 beds to enhance the availability of Covid healthcare facilities

- Import of oxygen concentrators and generators to ease the burden on the country’s healthcare system

- Provision of essential healthcare infrastructure and supply of PPEs to hospitals in several states

- Supply of dry ration kits or cooked food to the needy and vulnerable groups

The Company’s overarching commitment to create significant and sustainable societal value is manifest in its CSR initiatives that embrace the most disadvantaged sections of society, especially in rural India, through economic empowerment based on grassroots capacity building. Towards this end, the Company adopted comprehensive CSR Policy outlining programmes, projects and activities that the Company plans to undertake to create a significant positive impact on identified stakeholders. All these programmes fall within the purview of Section 135 read with Schedule VII of the Companies Act, 2013 and the Companies (Corporate Social Responsibility Policy) Rules, 2014.

The key elements of the Company’s CSR interventions are to:

- Deepen engagement in identified core operational geographies to promote holistic development and design interventions in order to respond to the most significant development challenges of the Company’s stakeholder groups

- Strengthen capabilities of Non-Government Organisations (NGOs)/Community Based Organisations (CBOs) in all the project catchments for participatory planning, ownership and sustainability of interventions

- Drive the development agenda in a manner that benefits the poor and marginalised communities in our factory and agri-catchments, thereby significantly improving Human Development Indices (HDI)

- Ensure behavioural change through focus on demand generation for all interventions, thereby enabling participation, contribution and asset creation for the community

- Strive for scale by leveraging government partnerships and accessing the most contemporary knowledge / technical know-how

Company’s stakeholders are confronted with multi-dimensional and inter-related concerns, at the core of which is the challenge of securing sustainable livelihoods. Accordingly, interventions under the Company’s Social Investments Programme are appropriately designed to build their capacities and promote sustainable livelihoods.

The footprint of the Company’s projects is spread over 25 States/Union Territories covering 216 districts.

Solid Waste Management (WOW Program)

Company’s initiatives focus on creating replicable, scalable and sustainable models of municipal solid waste management that can be implemented across the country to ensure that zero waste goes to landfills.

| Area Covered Under Plantations: 30,439 acres during the year. |

The Company’s pioneering afforestation initiative is currently spread across 17 districts in 8 States covering over 3.94 lakh acres in 5,694 villages, impacting over 1.28 lakh poor households. Together with the Company’s Farm Forestry programme, this initiative has greened over 8.76 lakh acres till date, and generated about 160-million person days of employment for rural households, including poor tribal and marginal farmers. Integral to the Social Forestry programme is the Agro-Forestry initiative, which cumulatively extends to over 1.23 lakh acres and ensures food, fodder and wood security.

This large-scale initiative also contributes meaningfully to the nation’s endeavour to create additional carbon sinks for tackling climate change.

In addition to the above, the Social and Farm Forestry initiative of the Company, through a multiplier effect, has led to improvement in pulpwood and fuel wood availability in Andhra Pradesh, Telangana, Karnataka, Chhattisgarh and Odisha. In the states of Tripura, Assam, Maharashtra, Uttarakhand and Karnataka, this initiative is also creating bamboo wood source that is suitable for agarbatti manufacturing.

| New Developments: |

The Company at its unit Bhadrachalam augmented its VAP capacity by 45000 TPA which will further strengthen its market standing. A significant increase in in-house pulp production was achieved during the year through strategic interventions, Industry 4.0 initiatives and improved wood mix.

| Product Launches: |

ITC-PSPD launched antifungal soap packaging paper designed to replace single-use plastics. It has also developed antiviral paper for applications in pharma and education & stationery businesses which is in the process of commercialisation.

| Raw Material Base: Wood, agro-residue, and waste paper |

JK Paper Ltd.

Creating Lasting Impressions

| Year of Establishment: | 1938 |

| Locations | |

| Headquarter: | New Delhi |

| Branches: | New Delhi (North), Kolkata (East), Mumbai (West), Chennai (South) |

| Mill 1: Mill 2: Mill 3: | Unit JKPM – Rayagada, Odisha Unit CPM – Fort Songadh, Gujarat Unit SPM – Sirpur Kaghaznagar, Telangana |

| Number of Employees: | 2655 |

| Paper & Paper Board Manufacturing Data: | |

| Production Capacity: | 2019-20: 5,91,000 TPA 2020-21: 5,91,000 TPA Current Capacity: 7,61,000 TPA* |

| Financial Information | |

| a) Turnover: | 2020-21: INR 2969.15 crore |

| b) EBITDA: | 2020-21: INR 701.41 crore |

| c) Net Worth: | 2018-19: 6210.8 crore |

| CSR Activities: |

Women Empowerment: More than 5500 tribal women from 178 peripheral villages were mobilised to form 531 self-help groups (SHGs). SHGs were empowered through training related to savings, credit, book keeping and supporting group economic activities. Collective enterprises emerged as sustainable livelihood opportunities. Rural Mart, Rayagada, was also established to support sales of SHG produce among other initiatives. Sustainable Farming: The Company helped form four FPOs, 84 farmer clubs, 184 farmer interest groups, and initiated 2 farmer resource centres. Mushroom farming was initiated among 87 farmers and about 8,500 saplings were planted on common land in collaboration with Social Farm Forestry Department, Gujarat. KVK Farmers’ Training was provided and farmer schools were established. Water resource development was initiated in Tapi and 35 acres were brought under soil erosion prevention though farm bunding, land leveling and nala plugging. Youth Engagement: Through NGO Bharatiya Yuva Shakti Trust (BYST), it reached out to 7115 youth under Youth Entrepreneurship Development Programme (YEDP). The company provided counselling support to 2144 youths, entrepreneurship training to 500 youths, and supported 80 youth enterprises. It has helped form 27 Youth Clubs and 27 Balika Mandals. It affiliated 85% Youth Clubs and Balika Mandals to Nehru Yuva Kendra Sangh (NYKS), trained 698 individuals across 11 trades, and Organized E-career counselling for employment among other activities. Community Healthcare: JK Paper undertook initiatives to provide free medical checks, treatment and medicines. The Company improved healthcare access through dedicated platforms (Balika Mandals) to handhold adolescent girls in the subjects of personal hygiene, reproductive and sexual health. The healthcare initiatives included access to quality primary care services to underprivileged communities, conducting need-based health camps and providing consultation and medicines, among others. The Company ensured better maternal and child healthcare services; and provided mobile health care services for patients finding it difficult to travel. Holistic Education: JK Paper undertook initiatives to educate local communities and counter centuries-old exploitation. A ‘green campus’ programme was conducted in partnership with Climate Reality Project, USA under which the teachers and students were trained to move to sustainable practices; this comprised solar and LED lights, waste segregation and composting, rain water harvesting, etc. it supported Nutan Gyanvardhini, the only school for children with special needs in Rayagada district and imparted digital literacy trainings to 376 youth/children. Rural Infrastructure Development: With the Government advocating the cause of rural infrastructure, the Company built crematoriums, village approach roads and overhead water tanks. Four villages were being supported for drinking water in Tapi. Seven locations were supported with a water cooler and purifier and An RO plant was provided in ITI, Ukai. Besides this, Mobile RO water unit was supported since Cyclone Fani and the Mission One Million Fruit Tree plantation programme, was launched. COVID-19 Response Under ‘COVID-19 Awareness and Relief Programme’, the Company covered 58 villages of Songadh and Ucchhal blocks of Tapi district, supported 1,624 marginalised households of primitive tribal groups, distributed Health and Safety essential kits among 2,797 households in 13 villages, and undertook COVID-19 safety awareness campaigns in over 150 villages. JK Paper, through its NGO network also distributed food in Puri and Bhubaneswar. |

| Area Covered Under Plantations: 32,700 acres (in 2020-21), cumulatively more than 4.65 Lac acres |

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Water: | 2020-21: 30.60 M3/Tonne |

| Energy: | 2020-21: 952 kWh/Tonne |

| New Developments: |

JK Paper Ltd. has recently installed new multi-layer board machine that has an annual capacity of 170,000 TPA in Unit CPM*.

Unit SPM commenced farm forestry plantation promotion activities in its mill catchment areas through advanced clonal technology. The Company installed a new power plant (130TPH AFBC boiler and 20 MW turbine), which helped achieve 100% power generation through captive sources and improve equipment reliability.

In 2019, the company was certified as a great place to work and ranked amongst top 100 companies in India as a great place to work.

| Export Markets: |

Reaching out to over 62 countries (including the US, the UK, Sri Lanka, Bangladesh, Singapore, Malaysia, Africa and the Middle East).

| Future Plans: |

The Company intends to widen its product mix following the introduction of products like liquid packaging, cigarette board, anti-fungal board and aqueous boards. In addition, JK Paper’s new packaging board capacity is likely to start production from the second half of the FY 2021-22. The new pulp mill will operate around chlorine-free technology, generate superior pulp, deliver a better board quality and report a lower cost of production, strengthening competitiveness. The increase in capacity will broad base the Company’s market risk and portfolio, strengthening its competitiveness across market cycles.

The Company plans to install new automated refiners and centri-cleaners in Paper Machine 1 in Unit JKPM. The Company plans to undertake a digital transformation journey in key manufacturing processes to reduce process variations, improving quality, cost economy, deliver better, faster service & create direct connect with the end customers.

The Company has launched digital transformation journey drive to enable & make the processes more capable to deliver better, faster and dependable solutions to its customers.

| Raw Material Base: 100% wood via social farm forestry. |

BILT Graphic Paper Products Ltd. (BGPPL)

| Year of Establishment: | Unit Ballarpur: 1953 Unit Bhigwan: 1996-97 |

| Locations | |

| Headquarter: | Gurugram, Haryana |

| Mill 1: Mill 2: | Unit Ballarpur, Chandrapur, Maharashtra Unit Bhigwan, Pune, Maharashtra |

| Paper & Paper Board Manufacturing Data: | |

| Production Capacity: | |

| Unit Ballarpur: | 2020-21: 3,00,000 TPA 2019-20: 3,00,000 TPA |

| Unit Bhigwan: | 2020-21: 3,15,000 TPA 2019-20: 3,15,000 TPA |

| Actual Production: | |

| Unit Ballarpur: | 2020-21: 1,79,000 TPA 2019-20: 2,56,000 TPA |

| Unit Bhigwan: | 2020-21: 2,14,000 TPA 2019-20: 2,49,000 TPA |

| CSR Activities: | |

| Avantha Group believes that business sustainability is connected to the sustainable development of the communities and the environment. Livelihood Creation: Livelihood interventions are implemented at the farm level for communities that are predominantly agrarian and through vocational education and skill building for youth to give them access to better job markets. Some of the successes are in the area of improved agricultural practices, animal husbandry and poultry that substantially augment incomes of farmers and take them from subsistence to surplus. Youth are trained for new age jobs in the service sector. Women Empowerment: The BILT CSR programmes have brought women, who have traditionally been neglected and excluded from the development process, into the centre stage of the decision-making and made them agents of change in their own communities. Formation of Self Help Groups, Credit Co-operative Society helping a large number of women to gain financial independence through micro enterprise ventures has been the key highlight. Education for the Underprivileged: Education is a critical component of any development programme. BILT’s CSR programmes focus on the improving the levels of learning in children in the age group of 6 to 14 years. This is done through bridge programmes that get children back into schools, remedial education programmes that prevent children from dropping out and Libraries that encourage children to read and retain their interest in education. In addition, BILT runs some innovative programmes like the ‘Mobile Computer Literacy’ programme that delivers computer education through busses to school in far flung areas. Community-Based Health Intervention: BILT’s collaborative health intervention programme involves both awareness and prevention. These projects help augment government medical services at the grass-roots through village health workers. A focus on maternal and child health issues has ensured that this critical issue is addressed at the right time. The availability of health providers at the doorstep gives timely help to communities on their minor health issues and better awareness regarding diseases and their prevention. HIV/AIDS Prevention: The HIV/AIDS awareness and prevention programme covers employees, their families, community members and high-risk groups such as truckers and transporters who work with the group companies. The HIV/AIDS awareness programme has reached over 200,000 people at the workplace and in the communities. Bilt runs two ART centres (at Ballarpur in Maharashtra & at Koraput in Odisha) that cater to the needs of people living with HIV/AIDS in ‘Public Private Partnership’ with NACO, MSACS & OSACS. Natural Resources Management & Preservation of Environment: Responsiveness towards a cleaner and safer environment is an important commitment that includes ensuring proper management and regeneration of water, waste management & preservation and conservation of forests. Over years, the company has worked closely with the communities & irrigation department of Govt. of Maharashtra for rehabilitation of the Canals, Renovations of the Check-dams and Water Harvesting Structures and Nala Plugs. These structures have been de-silted and major & minor repair works were carried out so as to increase their efficiency of holding rain water. Deepening of village ponds and putting up Bore-wells for drinking water purpose, well recharges are some of the other examples of the work BILT has undertaken at its plant sites Bhigwan near Pune in Maharashtra & Jeypore in Koraput District, Odisha. Awards & Recognitions: BILT has received a number of Awards including the TERI CSR Award, The Golden Peacock Global CSR Award and the Asian CSR Award for its community initiatives & contributions to Natural Resources Management. |

| Area Covered Under Plantations: | 2020-21:2,175 Ha 2019-20: 2,022 Ha |

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Unit Ballarpur: | 2020-21: 48.6 m3/MT 2019-20: 42.8 m3/MT |

| Unit Bhigwan: | 2020-21: 14.5 m3/MT 2019-20: 14.3 m3/MT |

| Product Launches: |

| Unit Ballarpur: Infinity bond, Paper for Cupstock, Product for Paper Straw, Copier Paper & Matrix Digital Paper, MG Poster for Thermal Coating, Glass Interleaving and Textile Transfer Printing. Unit Bhigwan: C1S G 50 GSM paper for metallisation and CPP lamination, CCK (Ink rub off) paper 50 GSM, Uncoated high strength 45 & 52 GSM-suitable for both side aluminum lamination for flexible packaging. |

| Export Markets: Exporting to 60+ countries in all continents |

| Raw Material Base: |

| Unit Ballarpur: Pulp produced in integrated pulp manufacturing facility (Produced with continuous digester and ECF bleaching process with bamboo, eucalyptus, subabul in raw material mix.) Unit Bhigwan: Purchased pulp |

Tamil Nadu Newsprint and Papers Ltd.

Consistent Growth. Continued Excellence

| Year of Establishment: | 1979 |

| Locations: | |

| Headquarter: | Guindy, Tamil Nadu |

| Branches: | Ernakulam, Hyderabad, Bengaluru, Mumbai, DelhI, Kolkata and Ahmedabad |

| Mill 1: Mill 2: | Kagithapuram, Tamil Nadu Mondipatti, Tamil Nadu |

| Number of Employees: | 2500 approximately |

| Paper & Paper Board Manufacturing Data: |

| Production Capacity: | |

| Writing & Printing: | 2020-21: 4,00,000 TPA 2019-20: 4,00,000 TPA |

| Multilayer Board: | 2020-21: 2,00,000 TPA 2019-20: 2,00,000 TPA |

| Actual Production: | |

| Writing & Printing: | 2020-21: 3,23,588 TPA 2019-20: 3,92,250 TPA |

| Multilayer Board: | 2020-21: 1,71,711 TPA 2019-20: 1,72,776 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 2819 crore 2019-20: INR 3509 crore |

| EBITDA: | 2020-21: INR 330 crore 2019-20: INR 644 crore |

| Net Worth: | 2020-21: INR 1597 crore |

| CSR Activities: |

| TNPL spent 2% of the average net profits of the Company made during three preceding financial years for community development activities under the broad sectors which include education, health care and medical service, infrastructure development, social development, livelihood/economic development, environment and sanitation, culture & heritage, soil and water conservation. |

| Area Covered Under Plantations: 1,87,680 acres from 2004-2020 (pulpwood plantations) |

Product Launches:

- Aura Green Flute: Developed for hot and cold beverages

- Aura Green Supreme: Cupstock variety for hot and cold beverages with superior printability

- Aura Wad Plus: For inductive application

- SPECTRUM: Copier paper in 70, 75 & 80 GSM

| Export Markets: Exports approximately 20% of its production, annually. |

Century Pulp and Paper

Touching Lives in More Ways Than One

| Year of Establishment: | 1984 |

| Locations: | |

| Registered Office: | Mumbai, Maharashtra |

| Branches: | Delhi, Mumbai, Kolkata |

| Mill: | Lalkuan, Uttarakhand |

| Number of Employees: | 3,229 |

| Production Capacity: | 2020-21: 4,86,000 TPA 2019-20: 4,45,000 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 1,774 crore 2019-20: INR 2,383 crore |

CSR Activities:

| Paper & Paper Board Manufacturing Data: |

At Century Pulp and Paper, a total amount of INR 11.3 crore was spent on CSR activities during FY21.

Community Help: Under this initiative, general and ladies waiting room was upgraded at Bharuch (Gujarat) railway station. In Lalkuan, Nainital (Uttarakhand), activities such as – cleaning of slum areas; construction of toilets; maintenance of parks in Haldwani and Nainital; construction of roads, drains, culverts and retaining walls at Bindukhatta and Shantipuri, were undertaken. In addition, the Company undertook efforts for the provision of drinking water by installation of India Marka Hand Pumps and RO systems, and provision of cattle feed at Gaushala. Overall, efforts for the upliftment of socio-economic standards in rural districts of Nainital, were an important part of the initiative.

Livelihood and Women Empowerment: In Jhagadia, Bharuch, the company installed 240 spindles ring frame, looms and also a training centre at Sewa Rural to facilitate the training and development of rural people. In Lalkuan, Nainital, the company started skill development programme for students of ITI Bindukhatta and 4 training centres and skill development for females.

Healthcare: Within the Healthcare initiative, labour room for PHC was developed, and hospital equipment was supplied. Also, medical camps, blood donation camps, medical awareness campaigns for females, and drug addiction awareness campaigns were organised. In addition, medical mobile vans for disabled were

Education: The focus of the initiative is on school education development with focus on creating an adequate infrastructure for school children. Under this program, four classrooms was constructed at Umadhra High School, Bharuch. In addition, library, stage and other infrastructure was developed at Valia Primary School. Toilets and boundary wall at Taropa Government School was also developed. In Lalkuan, the renovation activities of primary schools, construction of rooms, furniture, computers in government schools at Bindukhatta and Shantipuri, were undertaken. Apart from this, smart classes at Baddi were started.

COVID-19 Response:

- Helped sanitise tribal areas and some parts of Lalkuan, Nainital

- Sensitised people on the safety precautions and measures during the pandemic

- Helped generate livelihoods by manufacturing masks and other products, especially for women during difficult times

- Distributed free ration and PPE kits during lockdown

- CPP team distributed 1.5 lakh litres of sanitiser and masks

- Infrastructure development of community centre to maintain social distancing

- Financial assistance to Chief Minister’s Funds

| Area Covered Under Plantations: Total 7.2 lakh trees planted in FY21. |

Water & Energy Consumption Per Tonne of Paper Produced:

| Water: | 2020-21: 32 m³/Tonne |

| Power: | 2020-21: 14 lakh units/day |

| New Developments: |

- New Tissue Plant to manufacture Prime Grade Tissue Paper with a capacity of 100 TPD was installed during the year. Trial run of the plant was held on 14th March, 2021

- Blow heat recovery utilised to generate heat in process applications and for steam saving, efficient secondary air heater has been installed

- Installed burner at lime kiln for higher utilization of PG gas, in place of FO and a centralised refining system to feed pulp for the need of multiple plants

- Improved turbine vacuum and optimised PGP’s consistency to save refining energy

- For steam valve optimisation to minimize MP steam peaks in various pulp mills

- Continued usage of black liquor & pith (Biomass product) for steam generation and CMG at Tissue plant in place of LPG

- Utilisation of solar energy – solar power plant 2.6 MWp on BOT model

- Centralize refining system for WPP, Paper Machines (PM) 3 & 4

- Upgradation of COL system at PM 3 and utilisation of Industry 4.0 at PM 4

- Installation of Meloni filter at Fiberline and an anaerobic system for effluent treatment

- Collaboration with international chemical suppliers like HeiQ and health guard for their anti-microbial technology. Also, developed an in-house patented technology for application of antimicrobial formulation

- Upgradation of WPP machine calendar

| Product Launches: |

- Disposable Bed Roll: Century developed disposable bed rolls made of high wet strength tissue, based on 100% green concept, especially for use in OPDs to prevent patients from COVID-19 and other infections.

- Barber Hygiene Kit: Developed a hygienic solution for salons, with 100% biodegradable tissue-based product, which can replace the clothes and towels used by the salons. The kit includes barber cutting cape, beard shaving cape and napkin.

- Century High BF Kraft Paper: Developed high BF kraft paper by using virgin unbleached pulp, an eco-friendly, food grade product.

| Export Markets: |

| Parts of Africa, Europe, CIS, the Middle East, North & South America, Australia, and Asia. |

| Future Plans: |

| Century Barrier Coated Paper: The company is developing biodegradable and compostable barrier coating to paper, for providing sustainable solutions with plastic coating replacement in the food packaging industry. While it has successfully replaced PE Coated paper cups and food containers with BioPBS based barrier coating to paper cups and food containers, the company is further working on developing 10 products to replace plastic coating. |

| Raw Material Base: |

| A variety of raw materials and pulpable raw material species (eucalyptus, poplar, veneer waste, bamboo, bagasse and recycled waste paper). |

(*Information sourced from Annual report)

West Coast Paper Mills Ltd.

Your Partner in Progress

| Year of Establishment: | 1955 |

| Locations: | |

| Corporate Office: | Kolkata, West Bengal |

| Branches: | New Delhi, Mumbai, Chennai, Bengaluru, Hyderabad, Kolkata |

| Mill: | Dandeli, Karnataka |

| Number of Employees: | 2418 |

| Paper & Paper Board Manufacturing Data: |

| Production Capacity: |

| Paper & Board: | 2020-21: 3,65,000 TPA 2019-20: 3,65,000 TPA |

| Actual Production: | |

| Paper & Board: | 2020-21: 229017 TPA 2019-20: 313876 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 1281 crore 2019-20: INR 1866 crore |

| EBITDA: | 2020-21: INR 201.05 crore 2019-20: INR 528.79 crore |

| Net Worth: | 2020-21: INR 1298.44 crore 2019-20: INR 1295.53 crore |

CSR Activities:

INR 353.02 lakhs spent on CSR initiatives which include health care programs, education support programs, promotion of social activities & creation of infrastructure, protection of natural resources & sustainability, protection of national heritage, making available safe drinking water, eradicating hunger, poverty & malnutrition and rural development support.

The Company also established one PSA Oxygen Plant for 50 patient’s requirements in Dandeli Government Hospital which was started in Aug 2021. This noble initiative will help the local community for timely availability of oxygen and development of medical infrastructure in Dandeli for future use.

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Water: | 2020-21: 74 m³/MT 2019-20: 63 m³/MT |

| Energy: | 2020-21: 1376 kWh/MT 2019-20: 1277 kWh/MT |

| New Developments: |

- Fiberline upgradation

- New chipper house

- New CD filter

| Product Launches: Plastic-free coated cupstock paper board |

Export Markets: Export of paper & board during the year was 2038 MT worth INR 12 crore (FOB) as against 3588 MT worth INR 21 crore (FOB) in the last year.

| Future Plans: |

The Company is continuously working phase wise investment at Paper Division, Dandeli for improving paper quality, producing new speciality products and reducing of usage of steam, power, chemical, water and also minimizing the breakdown of machines.

| Raw Material Base: | |

| Wood: | 2020-21: 4.38 MT/MT 2019-20: 4.29 MT/MT |

(*Information sourced from Annual Report)

N R Agarwal Industries Ltd.

Culture of no compromise

| Year of Establishment: | 1993 |

| Locations: | |

| Regional Office: | Mumbai, Maharashtra |

| Mill 1: | Vapi, Gujarat |

| Mill 2: | Sarigam, Gujarat |

| Number of Employees: | 1505 |

| Paper & Paper Board Manufacturing Data: |

| Production Capacity: |

| Duplex: | 2020-21: 1,80,000 TPA 2019-20: 1,80,000 TPA |

| Newsprint and W&P: | 2020-21: 1,74,000 TPA 2019-20: 1,74,000 TPA |

| Actual Production: | |

| Duplex: | 2020-21: 1,67,692 TPA 2019-20: 1,81,827 TPA |

| Newsprint: | 2020-21: 777 TPA 2019-20: 3447 TPA |

| Writing & Printing: | 2020-21: 1,16,037 TPA 2019-20: 1,53,689 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 1145.63 crore 2019-20: INR 1404.92 crore |

| EBITDA: | 2020-21: INR 140.94 crore 2019-20: INR 228.34 crore |

| Net Worth: | 2020-21: INR 476.49 crore 2019-20: INR 418.78 crore |

| CSR Activities: |

The Company has spent a total amount of INR 264.96 lakhs towards CSR initiatives.

- Healthcare: INR 224.46 lakhs

- Education: INR 40 lakhs

- Infrastructure/Cultural/Environment: INR 0.50 lakhs

| Export Markets: |

| Around 15% is dedicated to export of total production. The major export markets include Sri Lanka, the UAE, Belgium, Vietnam, Bangladesh, Kenya, East Africa etc. |

| Raw Material Base: 100% waste paper |

Emami Paper Mills Ltd.

Together We Grow, Together We Create A New World

| Year of Establishment: | 1981 |

| Locations: | |

| Regional Office: | Kolkata, West Bengal |

| Branches: | Mumbai, New Delhi, Hyderabad |

| Mill: | Balasore, Odisha |

| Number of Employees: | 2975 |

| Paper & Paper Board Manufacturing Data: |

| Production Capacity: |

| Paper Board: | 2020-21: 2,00,000 TPA 2019-20: 1,80,000 TPA |

| Newsprint, W&P & Kraft: | 2020-21: 1,40,000 TPA 2019-20: 1,40,000 TPA |

| Actual Production: | |

| Paper Board: | 2020-21: 1,82,237 TPA 2019-20: 1,76,756 TPA |

| Newsprint, W&P & Kraft: | 2020-21: 61,632 TPA 2019-20: 1,36,888 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 1216.27 crore 2019-20: INR 1515.32 crore |

| EBITDA: | 2020-21: INR 181.46 crore 2019-20: INR 247.92 crore |

| Net Worth: | 2020-21: INR 539.46 crore 2019-20: INR 218.92 crore |

| Growth Rate: | Turnover: (-) 20% |

CSR Activities:

- The company puts sincere effort to enrich life of under privileged inhabitants of surrounding villages by developing infrastructures like drinking water supply, laying and improving roads, culverts, providing lighting facilities, development of parks etc.

- As a responsible corporate citizen, apart from generating indirect employment for its stakeholders in & around factory area, the company has developed huge plantation area within its premises as well as encourages people to develop greenery by distributing sapling to local people, schools and colleges.

- The company has taken its social responsibility as a part of its operating policy and conducting its social activities to promote inclusive and sustained growth.

- The company has incurred INR 0.48 crore in 2020-21 and INR 1.50 crore in 2019-20 towards CSR activities.

| Area Covered Under Plantations: 53 acres |

| Water: | 2020-21: 10.1KL/Tonne 2019-20: 13.5KL/Tonne |

| Energy: | 2020-21: 622 kWh/Tonne 2019-20: 683 kWh/Tonne |

| Coal: | 2020-21: 1.021 Tonne/Tonne 2019-20: 1.039 Tonne/Tonne |

New Developments:

- Increased share in the market of virgin grade writing & printing paper

- Developed high BF kraft paper

- Developed sources for cost effective procurement of waste paper

- Arranged linkage source for 100% coal requirement

- Developed export market for paperboard and kraft

| Product Launches: |

- Virgin grade writing and printing paper

- Super fine print paper (Lower GSM)

- White top liner

- Coated virgin back board

- Eco carry kraft paper

- Copier grade paper developed in A4 & FS sizes

- Azure laid grade were developed for indigenous market

| Export Markets: |

During 2020-21, the Company exported 10,000 MT of Kraft Paper to South-East Asian countries. It also exported around 60000 MT of Packaging Boards to different countries and have established itself as a premium grade finest quality board manufacturer and the quality has been approved by International multinational giants like Unilever, Colgate Palmolive, Heineken, Nestle, etc.

| Future Plans: |

- 10% capacity increase by upgradation and modernization of Paper and Board Machines

- Modification of PM3 with installation of Size Press for manufacturing of writing & printing paper and high BF Kraft Paper

- The company based on its fungibility in its 3 paper machines is now comfortable in catering market demands for Writing and Printing Paper /Newsprint /Kraft Paper

- The company is also focusing on Niche products/Value added products in the above categories

- Water consumption is being optimized along with increased use of recycled water in order to reduce consumption of fresh water by 20%

| Raw Material Base: |

| Waste Paper: | 2020-21: 53% 2019-20: 61% |

| Imported Pulp: | 2020-21: 47% 2019-20: 39% |

Bindals Group

Passion, Planet, Paper

| Year of Establishment: | 2009 |

| Locations: | |

| Headquarter: | New Delhi |

| Mill 1: | Bindals Papers Mills Ltd., Muzaffarnagar, Uttar Pradesh |

| Mill 2: | Tehri Pulp and Paper Ltd., Muzaffarnagar, Uttar Pradesh |

| Mill 3: | Agarwal Duplex Board Mills Ltd., Muzaffarnagar, Uttar Pradesh |

| Number of Employees: | 1300 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | |

| Paper & Paper Board: | 2020-21: 3,08,250 TPA 2019-20: 3,08,250 TPA |

| Actual Production: | |

| Paper & Paper Board: | 2020-21: 2,64,282 TPA 2019-20: 2,82,859 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 1009.03 crore 2019-20: INR 1145.89 crore |

| EBITDA: | 2020-21: INR 102.76 crore 2019-20: INR 107.86 crore |

| Net Worth: | 2020-21: INR 292.19 crore 2019-20: INR 262.44 crore |

| Growth Rate (Net Worth): | 2020-21: 11.5% 2019-20: 8.71% |

CSR Activities:

The company had spent INR 22 lakhs on its CSR activities in FY2019-20. For FY2020-21, the total CSR expenses were INR 34 lakhs. Bindals Papers Mills has contributed towards rain water harvesting in nearby villages, community hospital care, regular blood donation & eye care camps and supply of RO plants in nearby villages for pure drinking water.

| Area Covered Under Plantations: 6.41 Ha. |

Water & Energy Consumption Per Tonne of Paper Produced:

| Water: | 20 m³/MT |

New Developments:

Upgradation of pulp mill, paper machine and recovery plant.

| Product Launches: |

Cup Stock Paper, Envelope Paper, Bindals Classic Paper, Wedding Card Paper, Paper Plate Paper & Natural Shade Paper.

| Export Markets: |

35 countries with the main focus to the UK, the UAE, Nigeria, Iran, Ethiopia, Ghana, Kenya, and Oman.

| Future Plans: |

Production of high-end packaging grade paper.

| Raw Material Base: |

Wheat straw, baggase, farming wood & waste paper.

Andhra Paper Ltd.

| Year of Establishment: | 1964 Renamed in 2020 |

| Locations: | |

| Corporate Office: | Hyderabad, Telangana |

| Regional Offices: | New Delhi, Kolkata, Mumbai, Bengaluru, Kochi, Chennai |

| Mill 1: | Unit Rajahmundry – East Godavari, Andhra Pradesh |

| Mill 2: | Unit Kadiam Mandalam – East Godavari, Andhra Pradesh |

| Number of Employees: | 4843 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | 2020-21: 2,41,000 TPA 2019-20: 2,41,000 TPA |

| Actual Production: | 2020-21: 1,64,408 TPA 2019-20: 2,27,600 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 886.75 crore 2019-20: INR 1269.70 crore |

| EBITDA: | 2020-21: INR 71.70 crore 2019-20: INR 317.02 crore |

| Net Worth: | 2020-21: INR 975.22 crore 2019-20: INR 975.85 crore |

| CSR Activities: |

Andhra Paper Ltd. strives to accomplish the inclusive development of the communities through its CSR initiatives. The company spent INR 418 lakhs to address and engage in the areas of education, health & wellness and community engagement. Around 15 villages, 1 town and 6000+ households benefitted through CSR activities, 929681 kilo litres of safe drinking water supplied to communities under social accountability, essential food material worth INR 21 lakhs supplied to the needy at Rajahmundry and INR 10 lakhs donated to East Godavari District Collector under COVID-19 relief measures.

| Area Covered Under Plantations: |

4066 hectares during the year. 571 saplings & seedlings distributed through farm-forestry initiative.

| New Developments: |

- Attained OTIF score – 96%, one of best in paper industry

- Increased sale of Cupstock variants (Cupstock & bottom) by 169% (23,990 MT vs 8,915 MT) – Thus, increased sales in industrial segment by 10%.

| Product Launches: |

Phrama Print, Thermal Base Paper, Andhra SuperPrint, Cupstock variants, Virgin Kraft, Fresho Pack.

| Future Plans: |

- Optimise the existing production capability

- Customer base expansion

- Cost and efficiency improvement

- New business development

- Farm-forestry initiatives

| Raw Material Base: |

During the year, the company procured 43.8% certified virgin fiber (FSC 100%) and balance was FSC controlled material. It uses waste paper (Recovered Fiber) to produce writing and printing paper. It used 55% FSC controlled material and 11% of FSC RM (Reclaimed Material).

(*Information sourced from Annual Report)

Gayatrishakti Paper & Boards Ltd.

Believe in Consistent Quality

| Year of Establishment: | 1996 |

| Production started: | 2000 |

| Locations: | |

| Headquarter: | Mumbai, Maharashtra |

| Unit 1-Duplex Division: | Vapi, Gujarat |

| Unit 2-Kraft Division: | Sarigam, Gujarat |

| Number of Employees: | 713 |

| Production Capacity: | |

| Duplex: | 2020-21: 1,02,000 TPA 2019-20: 1,02,000 TPA |

| Kraft: | 2020-21: 1,32,000 TPA 2019-20: 1,32,000 TPA |

| Actual Production: | |

| Duplex: | 2020-21: 92,150 TPA 2019-20: 95,070 TPA |

| Kraft: | 2020-21: 1,19,881 TPA 2019-20: 1,22,865 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 704.53 crore 2019-20: INR 682.83 crore |

| EBITDA: | 2020-21: INR 93.15 crore 2019-20: INR 91.14 crore |

| Net Worth: | 2020-21: INR 185 crore |

| CSR Activities: |

The Company is associated with an NGO that is actively involved in education, medical and food for the welfare of poor and needy community. The NGO is well organized and serving to the society welfare since last two decades in the western India.

| Area Covered Under Plantations: 3000 meter (including plantation covered during FY21 of 500 Sqm) |

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Water: | 4 KL/Tonne |

| Energy: | 330 Units/Tonne |

| New Developments: |

Added the following technology in the plant:

- Refiner

- New OCC Pulper

- Jet Cooker

- Incinerator (Boiler) for plastic waste disposal

| Product Launches: |

In the year 2019-20, the company had concentrated on quality development on the existing product of Duplex Board and Kraft papers. The company was able to achieve superfine quality of both grade of Duplex and Kraft paper and got tremendous response from both domestic and international market by receiving repeated orders from renowned customers.

| Export Markets: Total 31.33% export |

- United Arab Emirates: 13.50%

- Sri Lanka: 12.95%

- Vietnam: 3.00%

- Malaysia: 0.60%

- Hong Kong: 0.55%

- Bangladesh: 0.53%

- Taiwan: 0.10%

- Sweden: 0.10%

| Future Plans: |

The company is in process to develop premium product in the near future to cater to the increased demand of product mainly White Top Kraft Liner Board and Kraft Pulp Board. The product mainly White Top Kraft Liner Board is being required by the packaging market in both uncoated and coated format. Both products are mainly used in the premium segment of packaging and the demand in both domestic and international market is growing gradually. The margins are usually high compare to usual product.

| Raw Material Base: |

100% recycled fibers obtained from waste papers.

Seshasayee Paper and Boards Ltd.

Fine Papers Lasting Impressions

| Year of Establishment: | 1960 |

| Commercial Production: | 1962 |

| Locations: | |

| Registered Office: | Erode, Tamil Nadu |

| Mill 1: | Unit Erode, Pallipalayam, Tamil Nadu |

| Mill 2: | Unit Tirunelveli, Mukkudal, Tamil Nadu |

| Number of Employees: | |

| Unit Erode: Unit Tirunelveli: | 1221 217 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | 2020-21: 2,05,000 TPA 2019-20: 2,05,000 TPA |

| Actual Production: | 2020-21: 1,70,138 TPA 2019-20: 1,97,547 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 781.79 crore 2019-20: INR 1183.98 crore |

| EBITDA: | 2020-21: INR 126.87 crore 2019-20: INR 289.57 crore |

| Net Worth: | 2020-21: INR 1101. 60 crore 2019-20: INR 985.96 crore |

| Growth Rate (Turnover): | 2020-21: (-) 33.97% 2019-20: (-) 10.66% |

| CSR Activities: |

Seshasayee Paper has spent INR 4.77 crore on its CSR activities. It has contributed INR 1.17 crore for running of schools and other educational institutions. Around INR 1.09 crore was spent on providing infrastructure facilities in nearby villages including Laying of Bitumen Roads, etc. and INR 0.76 crore for supply of drinking water to nearby villages. The company has provided INR 0.77 crore for Covid-19 relief packages and INR 0.98 crore for rural primary health centers.

Seshasayee Paper undertook a series of initiatives throughout the year, to help its employees, their families and those living around plants to combat Covid-19 pandemic. While re-commencing operations of the plant, a detailed Standard Operating Procedures (SOP) was put in place and Awareness Programmes were conducted for all employees.

The company provided face masks, gloves and other protection materials free of cost to all employees and nearby residents. In line with the Guidelines of Govt. of Tamil Nadu, Kabasura Kudineer (a herb based medicinal drink) was distributed, free of cost, to all its employees and residents regularly. Hand sanitizers were provided at mill entrance, all departments and also in public places around the Mill. Packets containing rice, grocery, cooking oil, etc. were distributed to those residing in containment areas as requested by District Collector, Namakkal.

Disinfectant was sprayed every day using a dedicated tractor all over the plant, residential colony and nearby villages. The company also assisted installation of key medical equipment, oxygen storage system, etc. in nearby government hospitals.

Employee Welfare:

- The company continued to approach the employees and all other stakeholders with high levels of empathy, to allay the fears and uncertainties in their minds that arose from Covid-19.

- SPB ensured 100% vaccination of all its employees and their families, including temporary workmen. The company has also worked with primary health in the nearby villages vaccinated. This has been a priority area over the last 12 months.

| Area Covered Under Plantations: |

| Area covered: | 2020-21: 19015 acres 2019-20: 16801 acres |

| Trees planted: | 2020-21: 16.40 crore 2019-20: 14.50 crore |

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Process Water: | 2020-21: 40 m³/Tonne 2019-20: 37 m³/Tonne |

| Power: | 2020-21: 1478 kWh/Tonne 2019-20: 1488 kWh/Tonne |

| Process Steam: | 2020-21: 5.94 Tonnes/Tonne 2019-20: 5.88 Tonnes/Tonne |

New Developments:

In the FY 2020-21, the Company had embarked on a Mill Development Plan-III (MDP-III) at Unit Erode at a cost of INR 315 crore.

The MDP-III at Unit Erode consists of:

- Upgradation and modernisation of the paper machines to increase the capacity from 1,32,000 tonnes per annum to 1,65,000 tonnes per annum

- Upgradation and modernisation of the RDH pulp mill to increase the capacity to 1,54,000 tonnes per annum

- Conversion of one paper machine to manufacture high end varieties of multi-layer boards.

- Upgradation of the recovery island

- Augmentation of waste water treatment plant

The execution of the Project (MDP-III) had commenced with July 1, 2020 as the Zero Date, with an originally planned project execution period of 21 months. However, with some of the major suppliers and service providers, both globally and in India, located in Covid-19-lockdown areas, the project has seen delays and the Company expects to complete the Project in entirety, in FY 2021-22.

Some of the major components of the project, namely (a) upgradation of Paper Machine No. 5, (b) upgradation of Paper Machine No. 1, (c) conversion of Paper Machine No. 2 for manufacture of single layer and multi-layer boards, have been completed. Other critical components of the project, namely (a) the upgradation of Paper Machine No. 3, (a) upgradation of Paper Machine No. 4 (c) upgradation of Recovery Island and RDH Pulp Mill, are expected to be completed in phases in the FY 2021-22.

The Company registered a lower PBT compared to previous year, mainly due to lower sales volumes and drop in net sales realisations in the current year, attributable in entirety to the significant reduction in demand for Printing and Writing Paper caused by lockdown imposed in multiple phases by Central / State Governments in India, to contain the spread of COVID-19 pandemic. As a result, profit after tax for the year ended March 31, 2021 was INR 100.27 crore, as compared to INR 173.46 crore, in the previous year.

The Company did not have any installments of Term Loans and interest (on Term Loans and Working Capital borrowings), due for payment during the year.

The Company reports NIL debt position as on March 31, 2021 (Debt Position as on March 31, 2020 was also NIL

The Company’s Quality Management Systems and Environment Management Systems continue to be covered under ISO 9001 and ISO 14001 Accreditations.

The Company continues to enjoy certification under Occupational Health and Safety Assessment Series 18001 (OHSAS) which is an international standard that facilitates management of Occupational Health and Safety risks associated with the business of the organization.

The Company has been certified under four Standards of FSC, viz. FSC-STD-40-004, FSC-STD-40-005, FSC-STD-40-003 and FSC-SSTD-50-001. By this, the Company assures its stakeholders that the wood and wood fibre (pulp) purchased by it are traceable to responsibly managed plantations and that adequate document controls are in place to ensure identification and traceability throughout the Chain of Custody. This also means that the Company is capable of manufacturing and selling FSC 100% and FSC Mix Products in the domestic and international markets.

The Company won the following Awards and recognitions during the year:

- CII SR EHS Excellence Awards for the year 2020: The Company secured 3-star rating from CII in appreciation of the EHS Practices of the Company.

- Tamil Nadu State Safety Award.

The Company continues to be accredited with “Star Export House” Status by the Government of India, Ministry of Commerce, Directorate General of Foreign Trade, in recognition of its export performance.

| Product Launches: |

- Azurelaid (High Smooth): Surface sized, high smooth, high strength ledger paper

- Pharma Paper: To be used as pharma insert in pharmaceutical segment

- Maplitho (CB): High strength maplitho paper for paper bag segment

- Virgin Kraft: Strong kraft paper for paper bag, pouches and corrugating applications

- MF Kraft (DS): Strong kraft paper for paper bag, pouches and corrugating applications

- Chromo-High Brite: One side coated paper with superior brightness

- SPB Prime: High quality base board for paper cups

- SPB Flora: High quality boards for paper plates

- SPB Momentz: High quality boards for wedding cards

- SPB Fusion: Bleached carton boards for corrugating applications

- SPB Carton Board: Bleached carton boards for corrugating applications

- Kraft Liner Board: Unbleached boards for corrugating applications

- Albella 70 GSM: Co-branded plain copier paper

- SPB Copier Deluxe 70 GSM: Plain copier paper

| Export Markets: |

Armenia, Afghanistan, Benin, Botswana, Bulgaria, Burkina Faso, Peru, Cambodia, Cameroon, Chile, Congo, Ethiopia, Ghana, Iran, Ivory Coast, Jordan, Kenya, Liberia, Madagascar, Malawi, Mauritius, Nigeria, Qatar, Rwanda, Senegal, South Africa, Sri Lanka, Sudan, Oman, Syria, Tanzania, Togo, Turkey, Uganda, UAE, USA, Vietnam, Yemen, Fiji, Kuwait, Lebanon, Mexico, Zambia.

| Export Sales Quantity: | 2020-21: 27983 Tonnes 2019-20: 36413 Tonnes |

| Export Sales % on Production: | 2020-21: 16.45% 2019-20: 18.43% |

| Future Plans: |

The Company is currently working on enhancing the capacity of Unit Tirunelveli through an appropriate product-mix.

| Raw Material Base (Quantity): | |

| Wood: | 2020-21: 270445 BDT 2019-20: 280739 BDT |

| Bagasse: | 2020-21: 15327 BDT 2019-20: 30608 BDT |

| Imported/ Indigenous Pulp: | 2020-21: 10074 ADT 2019-20: 15976 ADT |

| Re-Cycled Fiber (Waste paper): | 2020-21: 7410 ADT 2019-20: 19628 ADT |

| Raw Material Base (%): | |

| Wood: | 2020-21: 89% 2019-20: 81% |

| Bagasse: | 2020-21: 5% 2019-20: 9% |

| Imported/ Indigenous Pulp: | 2020-21: 3% 2019-20: 4% |

| Re-Cycled Fiber (Waste paper): | 2020-21: 3% 2019-20: 6% |

Trident Group

Being different is normal

| Year of Establishment: | 1990 |

| Locations: | |

| Headquarter: | Ludhiana, Punjab |

| Mill: | Barnala, Punjab |

| Number of Employees: | 16,111 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | 2020-21: 1,75,000 TPA 2019-20: 1,75,000 TPA |

| Actual Production: | 2020-21: 1,37,771 TPA 2019-20: 1,50,726 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 704.1 crore 2019-20: INR 922.5 crore |

| EBITDA: | 2020-21: INR 182.3 crore 2019-20: INR 310 crore |

| Net Worth: | 2020-21: INR 3316.6 crore 2019-20: INR 2966.9 crore |

| CSR Activities: |

Under SRIJANA initiative, Trident Foundation enlightens women about the importance of their health, spread awareness among adolescent females about the process of menstruation and other related aspects concerning hygiene. The company has touched approximately 10,500 women’s lives as they were introduced to better and hygienic ways to deal with menstruation. Apart from that, Trident has installed sanitary napkins vending machines in all its plant locations i.e Sanghera, Dhaula and Budhni where all menstruating women can obtain the napkin for free and the expense is borne by the company.

Trident Foundation has arranged to install 8 hand pumps in 11 villages of the state of Madhya Pradesh for better access to water. These hand pumps are serving approximately 18500 people providing them with safe and pure drinking water at all times. Also, an arrangement of 2 water tanks with a capacity of 1000 litres and installation of water taps in each of the above villages for storage of clean drinking water has been made.

The company has impacted over 200 families under Hastkala initiative by extending its support to several self-help groups of women in rural areas of Punjab and Madhya Pradesh.

Its holistic education initiatives ensure a healthy learning environment. Trident Foundation has currently renovated and built new rooms in four schools and two anganwadi centres in district Sehore. It has completely revamped the existing facility through the provision of desks and bench sets, availability of clean drinking water, toilets, construction of boundary walls, flooring, waterproofing of roofs etc. Keeping a full track of environment, the four schools and anganwadi centres are fully solar-powered equipped.

Under the project Swastha, quarterly free medical camps at Barnala are hosted for the vulnerable sections of society by the company.

To help women be self-dependent and restore livelihood for them, the company will be opening sewing skill centers across Barnala . “WeCare” loans are small initiative of assisting the internal members through the monetary loans per their personal needs at subsidized rates. Madhuban hospital is a health care facility targeted to serve the medicinal needs of below poverty line (BPL) people.

Besides these ongoing programmes for societal and community betterment, the team of Trident Foundation responds to regular blood donation camps, special camps for antenatal, pre-natal and post-natal health care for expecting and lactating women in villages of Sehore and Hoshangabad.

| Area Covered Under Plantations: |

| Budhini: | 212 acres |

| Sanghera: | 13 acres |

| Dhaula: | 213.5 acres |

| New Developments: |

In spite of the critical second wave of COVID, in the paper business, the company performed effectively achieving a turnover of INR 47,239 million in 2019-2020. Over the years, it has yielded several awards – the CII’s National Award for Excellence in Energy Management, Star Trading House FIEO Export Excellence Award, Indian Exporters Excellence Awards and the Government of India’s National Energy Conservation Award among many others.

Today, as an ISO 9001: 2008, ISO 14001:2015 and OHSAS 18001:2015 certified company, Trident has an impressive line-up of world-class office products such as laser printer paper, laser paper, inkjet printer paper, Bond paper, presentation paper and multi-purpose paper. Its various paper grades include Trident Spectra, Trident My Choice, Trident Natural, Trident Royal Touch, Trident Digi Print and the premium Trident Spectra Bond.

| Product Launches: |

Trident has launched bleached kraft paper, unbleached kraft paper, sublimation paper and ant-bacterial and eco-friendly notebooks under the name, “My Choice” and recorded a turnover of INR 45,353 million in 2020-2021.

The company delivers the best quality and eco-friendly paper, The Good Paper, made from wheat straw. Wheat straw is one of the most abundant agricultural wastes available in largely agrarian India. By using wheat straw, Trident is helping prevent large amounts of this resource from being burnt and causing air pollution. It is also providing an additional source of income to all its associated farmers.

The journey of the Good Paper which started from copiers has today taken many forms and expanded its horizons across a ‘world of possibilities’ – copier paper, anti-bacterial notebook, printing paper and a variety of specialty papers to make carry bags, drawing papers, wedding cards, soap wrappers, cup bottoms and many more utilitarian and eco-friendly products. The Good Paper is certified for causing fewer carbon emissions. It has also been pronounced a Superbrand two times in a row.

| Export Markets: |

15% of total production is exported to countries including Angola, Australia, Bahrain, Congo, DR Congo, Ethiopia, Greece, Haiti, Italy, Ivory Coast, Kenya, Kuwait, Liberia, Madagascar, Malaysia, Mauritius, Nepal, Oman, Qatar, Saudi Arabia, Siera Leone, Sri Lanka, Sudan, Tanzania, Lebanon Turkey, UAE, Uganda, Ukraine, Zambia, Maldives, Iraq, Georgia, Rwanda, Mozambique, Puerto Rico, New Zealand, Mauritania, Ghana, US, Canada, Burundi.

| Raw Material Base: | |

| Agro residue: | 60-70% |

| Wood pulp: | 30-40% |

Astron Paper & Board Mill Ltd.

Excelling with Innovation

| Year of Establishment: | Incorporated in 2010 Commercial Production in 2012 |

| Locations: | |

| Head Office: | Ahmedabad, Gujarat |

| Mill 1: | Halvad, Gujarat |

| Mill 2: | Bhuj, Gujarat |

| Mill 3: | Mehsana, Gujarat (Balaram Papers Private Limited-Wholly Own Subsidiary) |

| Number of Employees: | 329 (as at 31st March 2021) |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | 2020-21: 2,22,000 TPA 2019-20: 2,22,000 TPA |

| Actual Production: | 2020-21: 1,59,016 TPA 2019-20: 1,47,488 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 435.15 crore 2019-20: INR 358.90 crore |

| EBITDA: | 2020-21: INR 31.82 crore 2019-20: INR 35.81 crore |

| Net Worth: | 2020-21: INR 173.11 crore 2019-20: INR 163.62 crore |

| CSR Activities: |

Under it CSR initiatives — the company has contributed more than INR 51 lakhs towards Swachh Bharat Abhiyan, Gram Seva Trust, Dardionu Rahat Fund, Aadhar Foundation, Blind’s People Association, Vishv Umiya Foundation, Foundation for Drug Free Society, Mission Clean Ganga, Akshaya Patra, Avval among other initiatives.

| Export Markets: 16% of total revenue. |

Belgium, Iran, Bahrain, Dubai, Nepal, China, Vietnam, Cambodia, Malaysia, Bangladesh, Sri Lanka, Mauritius, the UAE, Yemen, Saudi Arabia, Kenya, Zimbabwe, Cameroon and Ghana.

| Future Plans: |

The company seeks to develop and adopt in-house strategies like global paper industry which would help to make functional changes and integrate whole process streamline from fiber to container. The strategy would help the company to backward and forward integration as its near future plans and to set milestone as one of the first players in Indian paper industry. Astron will appoint separate R&D team to develop market and bring innovations to every paper products available for rigid and fix packaging, and also replace banned plastic packaging with paper packaging at large scale. The Company is planning to launch new value-added products for both the domestic and export markets.

| Raw Material Base: |

Imported and indigenous waste paper.

(*Information sourced from Annual Report)

Silverton Pulp & Papers Pvt. Ltd.

Creating Paper to Your Needs

| Year of Establishment: | 2004 |

| Locations: | |

| Registered Office: | Muzaffarnagar, Uttar Pradesh |

| Mill: | Muzaffarnagar, Uttar Pradesh |

| Number of Employees: | 650 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | |

| Kraft Paper & Board: | 2020-21: 90,000 TPA 2019-20: 90,000 TPA |

| Newsprint, W&P & Other: | 2020-21: 1,08,000 TPA 2019-20: 1,08,000 TPA |

| Actual Production: | |

| Kraft Paper & Board: | 2020-21: 66,306.245 TPA 2019-20: 69,801.811 TPA |

| Newsprint, W&P & Other: | 2020-21: 58,925.588 MTPA 2019-20: 63,219.997 MTPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 467.82 crore 2019-20: INR 524.29 crore |

| EBITDA: | 2020-21: INR 63.42 crore 2019-20: INR 60.96 crore |

| Net Worth: | 2020-21: INR 145.48 crore 2019-20: INR 106.84 crore |

| CSR Activities: |

- During the second wave of COVID-19, the company has contributed to the society by donating oxygen concentrator.

- Provided continuously support to poor children by means of AKAL Vidhyalaya Scheme.

- Made donation on regular basis for the development of society.

| Area Covered Under Plantations: 6.5514 Hectare (33% of total land area) |

Water & Energy Consumption Per Tonne of Paper Produced:

| Kraft Paper: | Water: 3m³/Tonne Energy: 325 Units/Tonne |

| Writing and Printing: | Water: 10m³/Tonne Energy: 1000 Units/Tonne |

| New Developments: Development of various products including: |

- Cup Stock Base Paper

- Wedding Card Base Paper

- Carry Bag Kraft Paper

- Kraft Paper for E-commerce Bags

| Export Markets: |

UAE, China, Iran, Bangladesh & Nepal

- 2020-21: 11.67%

- 2019-20: 3.78%

| Raw Material Base: 100% Waste paper |

Dev Priya Products Pvt. Ltd.

| Year of Establishment: | 1998 |

| Locations: | |

| Headquarter: | Meerut, Uttar Pradesh |

| Mill: | Meerut, Uttar Pradesh |

| Number of Employees: | 600 |

Paper & Paper Board Manufacturing Data:

| Production Capacity: | 2020-21: 1,50,000 TPA 2019-20: 1,50,000 TPA |

| Actual Production: | 2020-21: 1,28,943 TPA 2019-20: 1,43,115 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 454.54 crore 2019-20: INR 477.04 crore |

| EBITDA: | 2020-21: INR 64.48 crore 2019-20: INR 50.67 crore |

| Net Worth: | 2020-21: INR 200.38 crore 2019-20: INR 157.52 crore |

| CSR Activities: Promotion of Education |

Area Covered Under Plantations: 200 trees planted in 50.16 Hectares (200 Bigha)

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Water: | 7 m³/MT |

| Energy: | 400 units/MT |

| Raw Material Base: Waste paper |

Satia Industries Ltd.

We Dream: We Deliver

| Year of Establishment: | 1980 |

| Locations: | |

| Headquarter: | Rupana, Punjab |

| Branches: | Delhi, Jaipur, Chandigarh, Raipur |

| Mill: | Rupana, Punjab |

| Number of Employees: | 1503 |

| Paper & Paper Board Manufacturing Data: |

| Production Capacity: | 2020-21: 1,05,000 TPA 2019-20: 1,05,000 TPA |

| Actual Production: | 2020-21: 1,20,501.4 TPA 2019-20: 1,33,191.1 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 588.44 crore 2019-20: INR 808.64 crore |

| EBITDA: | 2020-21: INR 136.12 crore 2019-20: INR 174.92 crore |

| Net Worth: | 2020-21: INR 445.35 crore 2019-20: INR 395.48 crore |

| Growth Rate: | Turnover: 38.32% (six months ended 30.9.2021 v/s six months ended 30.9.20) EBITDA: 36.10% (six months ended 30.9.2021 v/s six months ended 30.9.20) |

CSR Activities:

The guiding principle of Satia Industries Limited CSR programs is enabling people to lead a better life. The Company’s focus areas are Education, Health and Wellness and Environmental Sustainability. The Company’s participation focuses on operations where it can contribute meaningfully either through employee volunteering or by using core competency which develops solutions.

The surge of second wave in COVID-19 in India has happened quite suddenly and several states have imposed renewed COVID restrictions. Resultantly, the Company was able to expend INR 122.44 lakh on the CSR activities up to 31st March, 2021 and the balance required amount of INR 133.55 lakh (including INR 49,20,833 of the previous year) was expended by the Company for undertaking of Medical Oxygen Generation and Storage Plants at local area of District Sri Muktsar Sahib for countering Covid-19 and on promotion of education.

| Area Covered Under Plantations: |

540 acres (Eucalyptus plantations, developed as per Karnal Technology, which consumes total treated water discharge.)

| Water & Energy Consumption Per Tonne of Paper Produced: |

| Water: | 2020-21: 60 m³/Tonne |

| Energy: | 2020-21: 1300-1400 kWh/Tonne |

| New Developments: |

2020-21:

- Installation of Multifuel Boiler (a cost saving of appox. 250 million per year)

- Installation of 14 MW turbine

- Machinery procured for table cutlery segment

2019-20:

- Recorded highest production of 1,33,191 MT and capacity of CRP plant increased from 400-650 TPD

- Listing of SIL’s equity shares on NSE in July 2019

| Product Launches: |

Commercial production of cutlery segment to be started in the month of December 2021

| Export Markets: |

SIL currently has a presence in Sri Lanka & Nepal. SIL plans to expand its base in the Middle East, African countries and also with select European and American clientele, who seem to have evinced interest in sourcing green copier paper (premium quality) from India.

| Future Plans: |

The Company has an expansion plan of doubling the production capacity from 300 TPD to 600 TPD. It is under advance stage of implementation and will be fully operational in the FY 2023 when topline will touch INR 1400 crore from present peak level of INR 800 crore plus. EBIDTA margin will remain in the range of 21-24% and PAT margin is likely to remain at 10% plus. The Company has already ventured into moulded fiber cutlery with 4 TPD capacity to be fully operational in this year and company has ambitious plan to have a turnover of INR 100 crore in this segment alone in near future.

| Raw Material Base: |

| Agro & Venner/Wood waste: | 2020-21: 94-95% 2019-20: 94-95% |

| Waste Paper: | 2020-21: 5-6% 2019-20: 5-6% |

Ruchira Papers Ltd.

Committed to the Earth

| Year of Establishment: | 1980 |

| Locations: | |

| Registered Office: | Kala Amb, Himachal Pradesh |

| Mill: | Kala Amb, Himachal Pradesh |

| Number of Employees: | 1000 approximately |

Paper & Paper Board Manufacturing Data:

| Actual Production: | 2020-21: 1,23,974 TPA 2019-20: 1,34,048 TPA |

| Financial Information: | |

| Turnover: | 2020-21: INR 415.42 crore 2019-20: INR 481.01 crore |

| EBITDA: | 2020-21: INR 24.53 crore 2019-20: INR 44.06 crore |

| Net Worth: | 2020-21: INR 270.14 crore 2019-20: INR 264.56 crore |

CSR Activities

As a responsible business, Ruchira Papers is socially inclined and focuses on sustained and effective Corporate Social Responsibility Projects. It defines Corporate Social Responsibility as the way a Company balances it’s economic, social and environmental objectives while addressing stakeholder expectations and enhancing shareholders value. The employees are also encouraged to volunteer their time and skills and enjoy the experience of giving back to the communities in which they work

The Company has identified the projects in a participatory manner, in consultation with the interested communities and in consonance with Schedule VII of the Companies Act, 2013. Arising from this, the focus areas that have emerged are the Rural and Infrastructure Development, providing quality education, preventive health care, sustainable livelihood and environment sustainability.

| Raw Material Base: |

- Agriculture residue i.e wheat straw, bagasse and sarkanda along with softwood pulp and other fillers (For writing and printing paper)

- Waste paper (Indigenous and imported as per finished production requirement) and agriculture residue (For kraft paper)

Kuantum Papers Ltd.

The Paper Makers