The production of energy in the form of biogas is one of the most important features of today’s anaerobic treatment plants. The biogas can be used to warm up process water or to generate energy and heat in a combined heat power installation (CHP). However, in most cases the biogas from anaerobic systems contains a lot of sulphur or hydrogen sulphide which is harmful to other equipment.

Stop burning your power resource

Because of the sulphur issue many companies just burn their biogas in flares. They are in need of a reliable system that can desulphurise the biogas cheap and efficiently. Paques THIOPAQ® technology is the solution. With many years of experience and more than 150 satisfied customers, it is the most modern and flexible way to desulphurise biogas. The first installation was built 20 years ago in the Netherlands and is still up and running today.

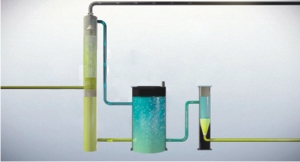

THIOPAQ® combines physical-chemical adsorption of hydrogen sulphide in a mild alkaline solution with biological regeneration of the caustic solution using air. The biogas containing hydrogen sulphide enters the absorber column and is washed by a scrubbing liquid with an alkaline nature that absorbs the hydrogen sulphide. The biogas exits the top of the absorber virtually free of hydrogen sulphide. The liquid containing sulphide flows to the bioreactor, where bacteria oxidise it and convert it under oxygen-limiting conditions to sulphur and caustic.

Case study – Landfill biogas

Paques has built many desulphurisation plants; for example this landfill in South East Asia.

The challenge here was to treat the enormous amount of 42,000Nm³ gas per hour with a high H2S concentration of 9,000 ppm. With a load of 10,000 kg sulphur per day, this is still the biggest THIOPAQ® installation that Paques has built up until today.

“Compared to 20 years ago, the technology has improved a lot”, says Erik van Zessen, Senior Process Specialist at Paques. “It is more robust, compact and the capacity per reactor volume has more than doubled.” At the landfill, an H2S removal efficiency of more than 97% is achieved. The clean biogas is used for power generation of up to 50MWe. The produced sulphur cake is also of value and can be sold or reused as fertiliser. “Biogas and large biogas flows will become more important in the future and the THIOPAQ® is the best way to desulphurise them!” van Zessen says.

Advantages

Paques has helped numerous customers to make use of their energy-rich biogas. The biogas from the THIOPAQ® is of exceptional quality as there is no oxygen introduced into it. This ensures the highest energy yield. The system has very low operational cost when compared to other systems and it also produces biosulphur which can be sold or reused as fertiliser. Paques constantly improves its technology in partnership with other companies. Together with Shell, the THIOPAQ® could be made available for the oil and gas industry. This know-how can also help you save a lot of money!