“Aqwise provides advanced water and wastewater treatment solutions built on a wide range of innovative biofilm-based processes.”

Mr. Suneet Kaul, Director of Sales-India, Aqwise Group enlightened us about the business story of the company, the various solutions they provide for the pulp and paper industry, the market reach, their product development process, and charts out the future plans in an exclusive conversation with Paper Mart.

Paper Mart: Could you please give us a glimpse into the business journey of Aqwise Group while presenting a brief rundown of the water and wastewater treatment solutions you provide for the pulp and paper industry?

Suneet Kaul: Aqwise is an industry leader in advanced biofilm-based water and wastewater treatment technologies — both anaerobic and aerobic, for industrial and municipal markets around the world. Its solutions are based on a wide range of innovative biofilm-based processes. Aqwise’s technology, a product of over two decades of multidisciplinary theoretical and practical research and development, positions the company as a world leader in its field. We deliver integrated, tailor-made solutions for both new and existing plants – from small scale compact units to large scale facilities.

The Company has a proven track record of more than 600 inst

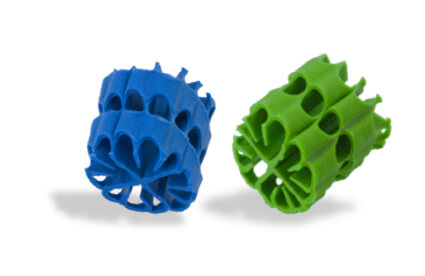

allations in a wide range of industrial and municipal sector applications in over 55 countries. We have a full-fledged R&D facility in Israel that has developed patented MBBR-based aerobic and anaerobic solutions such as AGAR® (Attached Growth Airlift Reactor) and DACS® (Downflow Anaerobic Carrier System), respectively. The AGAR® solution is a unique combination of an open and protected biomass carrier and a highly efficient aeration mixing design. It includes AGAR® MBBR and AGAR® IFAS to enable efficient BOD removal and intensive nutrient removal for both municipal and industrial clients.

DACS® is a high rate anaerobic process which utilizes a unique hydraulic design that improves the stability and performance of the treatment system. It includes the DACS® high-rate anaerobic process and DACS® DANA process, to enable simple and effective removal of COD and energy recovery for various industrial sectors.

The pulp and paper industry is known for its high water consumption and requires meeting high levels of wastewater treatment to allow safe discharge and reuse in the production. We provide anaerobic, aerobic and hybrid solutions to meet these needs, and effectively utilize water and energy resources.

“The Company has a proven track record of more than 600 Installation in a wide range of industrial and municipal sector applications, in over 55 countries.”

The solutions based on Aqwise technology offer numerous benefits and are used for new and upgradation of existing wastewater treatment plant, for BOD/COD and nitrogen removal and to increase the amount of nitrifying bacteria in existing activated sludge system using the Aqwise carrier in a hybrid plant to meet ammonia limits. Moreover, the Floating Carriers ensure faster and more stable processes in a high speed/load reactor in comparison with existing circulating systems with pellet of granulate sludge. With these favorable features, there is a significant improvement of efficiency in comparison with conventional technologies resulting in low CAPEX and OPEX.

PM: Kindly outline on the markets you serve with your solutions and your plans with respect to expanding your reach to unexplored markets.

SK: Aqwise offers both aerobic and anaerobic solutions for a diverse range of industrial and municipal needs and delivers integrated, tailor-made solutions for both new and existing plants – from small scale compact units to large scale facilities. Water and wastewater treatment for the industrial sector requires an in-depth understanding of industry-specific production processes, compliance with applicable local regulations, integration with physical and chemical processes, and a high-level of expertise to ensure maximum quality effluent for discharge and reuse up to zero liquid discharge (ZLD).

Aqwise’s solutions portfolio is quite suitable for deployment in a variety of industries, demonstrating process stability in harsh and variable conditions, adapting to ever-changing production needs.

PM: Please elaborate on the market footprint of Aqwise Group in the Indian pulp and paper industry. What is your outlook on the Indian pulp and paper industry with regard to water treatment and recycling? Do you have any plans of expanding your presence in the Indian market?

SK: For many years now, the Indian pulp and paper industry has been continuously expressing the need to improve its water and wastewater treatment and management practices, and some paper mills have undertaken pertinent actions in this direction.

Since 2015, Aqwise has been active in this sector, and has supported dozens of paper mills with designs for ETP upgrade and retrofits, eventually with a number of successful applications. We have substantial references of upgradation and Greenfield projects globally. In Italy, we have been successful references of 10 plants with our aerobic and anaerobic technology. We are certainly well positioned to support the Indian paper sector with the increase in activity in this field.

PM: What are the different features and competitive strengths of your wastewater treatment solutions for the pulp and paper sector?

SK: A strong biological process know-how and experience of successful installations has helped us in developing and providing customized solutions to the clients. With respect to the advantages, the solutions based on Aqwise’s technology are cost-efficient, has a small carbon footprint, and enables fast deployment. Besides, these solutions are scalable and has simple operation, are based on a flexible and innovative technology, are environmentally-friendly and manifest a significant improvement of efficiency in comparison with conventional technologies resulting in low CAPEX and OPEX.

PM: The pulp and paper industry is quite water-intensive and in view of the ongoing global water scarcity, and water usage restrictions, the reuse and water management techniques are becoming more prevalent and economical. How do you go about developing efficient technologies for wastewater treatment and water reuse?

SK: Aqwise’s technology, a product of over a decade of multidisciplinary theoretical and practical research and development, positioned the company as a world leader in its field. With a strong biological process know-how and multi-disciplinary expert staff, we’ve been able to develop and provide customized solutions to our clients. Our MBBR-based solutions have helped customers significantly reduce both the construction and maintenance costs.

Solutions based on Aqwise technology offer numerous benefits, including significant improvement of efficiency in comparison with conventional technologies resulting in low CAPEX and OPEX and there are three possible design variations enable maximum flexibility referring client demands. Further, there is no sedimentation or blocking of sludge, no requirement of expensive mixing/separation devices, no sludge loss because of power peaks, and moreover, it allows for the possible use of existing tanks instead of a predefined special tank design.

Our solutions enable the users to retrofit, reuse and recycling of existing equipment, materials and resources. As a matter of fact, our entire range of processes and products is designed to generate a minimal physical footprint and ensure a nonintrusive impact on the environment. Our technology provides clients with cost effective and environmentally-friendly solutions.

PM: Has there been any recent development at Aqwise Group that you wish to highlight? What are your strategies and plans for the future growth of the company?

SK: Aqwise is developing methodologies to apply its technologies to new and challenging applications emerging in today’s water space, i.e. ground water contamination, micro-pollutants, low load applications, effluent reuse, etc.

We are also focusing on the development of new types of biomass carriers, which will bring technical and process advantages to our clients, in addition to cost savings. The Indian market may be a focus for these new carriers, given the need to compete in the market with local media.