Gascogne Papier awarded a contract to ABB for the installation of the world’s widest uncoated machine-glazed (MG) paper machine at Gascogne Papier’s kraft pulp and paper production plant in France. Drives’ deliveries to Gascogne are planned for 2024.

Dec 14, 2023

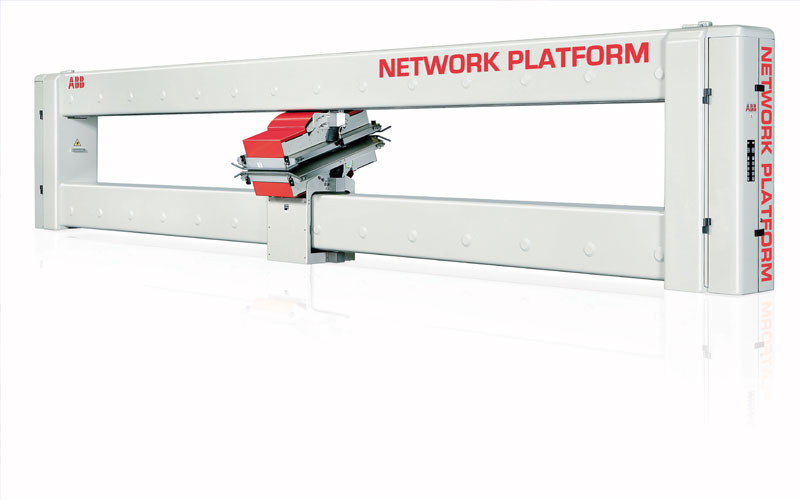

ABB has been selected as a project partner for the installation of the world’s widest uncoated machine-glazed (MG) paper machine at Gascogne Papier’s kraft pulp and paper production plant in Mimizan, France. Replacing three older machines, the facility’s PM7 will be fully integrated and standardized using the ABB Ability™ System 800xA® distributed control system (DCS), the ABB Quality Control System (QCS) for pulp and paper, drives, and motors. Advanced QCS controls will enable automatic grade changes and multivariable cross-direction. The full scope of supply includes 8000 I/O, ACS880 multi-drives, and ABB’s energy-efficient SynRM IE5 motors. The package will help Gascogne Papier save on energy costs while simultaneously reducing waste by making more on-spec paper. ABB began deliveries with QCS early in 2023 and drives deliveries to Gascogne are planned for 2024, along with the commissioning of the machine.

Watch: MLM Group to Import 25,000 TPM Forest Products

ABB’s technologies will be used on the new paper machine that has a web width of 6.8 meters and a design speed of 1,300 meters per minute. It will be capable of producing 125,000 tons per annum of basis-weight paper between 25 and 120 grams per square meter, setting a new industry benchmark for uncoated MG papers. IE5 ultra-premium SynRM motors are the same size and output power as commonly used IE2 induction motors but offer up to 50 percent lower energy losses and significantly lower energy consumption. Additional benefits include lower bearing and winding temperatures for enhanced reliability, long life, and less motor noise. They can be used in a wide range of demanding industrial applications for accurate control and high efficiency at a range of speeds.

Also Read: Nordic Paper to Invest USD 84 Million for Sustainable Kraft Paper Production

Ms. Pamela Murphy, European Operations Manager for Pulp and Paper at ABB, said, “We have an established relationship with Gascogne and are delighted to continue supporting them in their mill production goals. The project also underscores our important collaboration and the complementary technology and expertise that we will bring to Gascogne.”