“It is a zero discharge system as there is an acute shortage of freshwater throughout the year. This water scarcity has forced mills to use recycled water with high dissolved solids for wet-end additives preparation. This was the biggest challenge for HABER to show a significant improvement in program performance while ensuring the stability of the wet-end system.”

Vice President at Haber

Background Information

A duplex board customer was running a retention and drainage aid program using a conventional control system for more than a decade. The Customer wanted to improve the program performance and reduce variations using the latest automation control techniques. HABER approached the customer and had a detailed technical discussion to understand the requirements followed by a thorough system study.

Haber Approach

HABER has done a detailed system survey followed by lab evaluation using Britt Dynamic Jar and Drainage Tester for screening a suitable program keeping furnish and machine configuration in mind. Lab evaluation was repeated on different days to check the consistency of results considering the variation in furnish. Based on a detailed lab study, HABER had suggested a two-component retention and drainage aid program to achieve improved retention as well as drainage.

HABER adopted the below approach for program implementation:

• The program was started up after a thorough cleaning of the system.

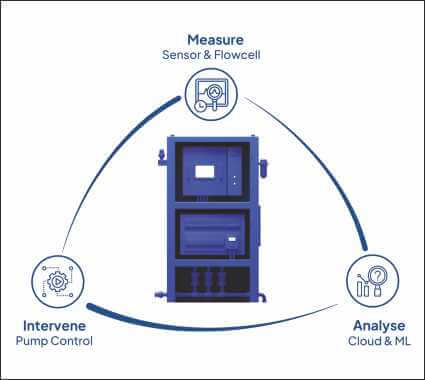

• A fully automated eLIXA® controlled chemical preparation and feed system are used for coagulant and flocculant.

• Installed sensors for real-time measurement of pH, Conductivity, Temperature, and Whitewater Consistency.

• Real-time measured values as well as offline data are uploaded to eLIXA® cloud and based on cloud data analysis, the chemical dosage optimization is done.

Customer Advantage

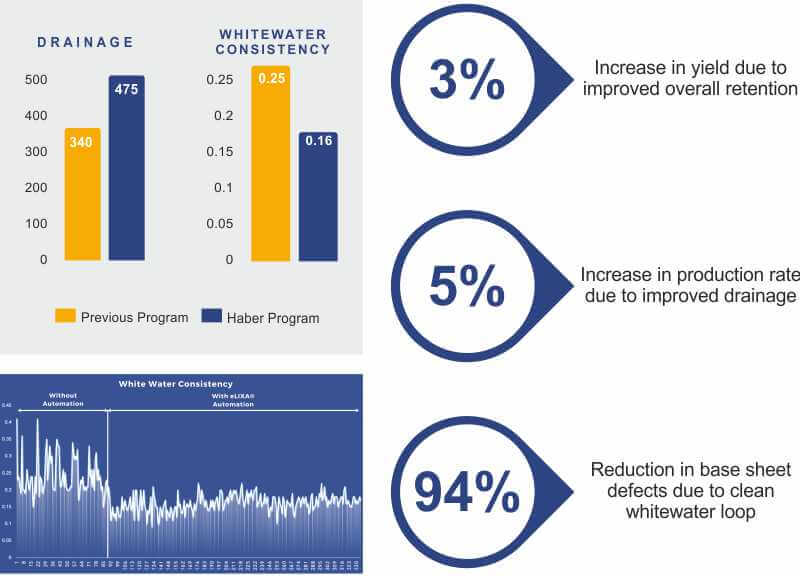

• After one week of starting the program, whitewater consistency was less by 21% compared to the previous programs and is maintained well within the target range.

• Drainage improved by 15% and resulted in reduced steam demand in the drying section resulting in an increase of production rate by 5%.

• Overall retention improvement has reduced the solids going to the wastewater treatment plant. This has improved the efficiency of the wastewater treatment plant and ensured minimum colloidal substances and suspended solids getting circulated in the system. Since it is a zero discharge system, this improvement helped reduce the problems related to spoilage, stickies, and odor in the paper machine system significantly.

• Because of the consistent performance of the RDA improvement program, sludge generation has come down drastically, giving great relief to the customer in solid waste disposal management as the sludge has a very high amount of inorganic which cannot be used in the process nor in the boiler.

• A significant improvement in overall retention has increased the yield by 3% and reduced the downtime by 95% because of stickies-related issues.