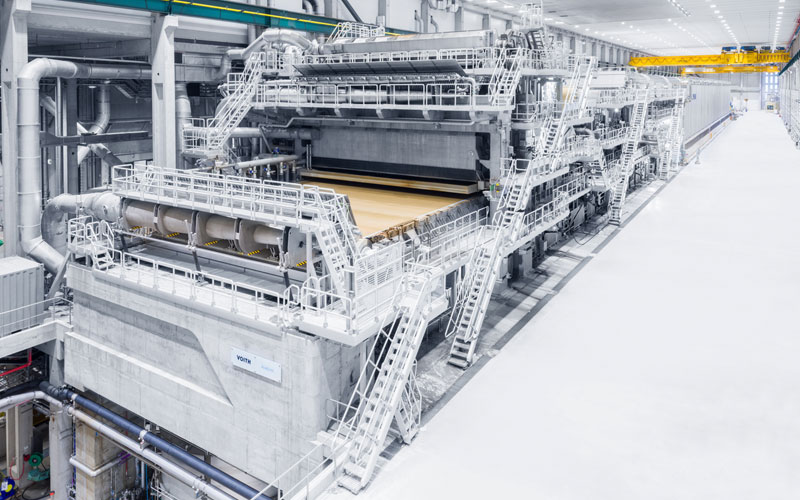

SCA’s Obbola, Sweden site houses an XcelLine PM 2 supplied by Voith. SCA is continuously collaborating with Voith to integrate digital and automated solutions for its high-performance kraft liner. The company has also entered into a service agreement with BTG, Voith’s subsidiary, for process control.

Jun 6, 2023

SCA is successfully utilizing Voith’s digital and automation solutions with the aim of optimizing the production efficiency of its new XcelLine PM 2. Last year, Voith supplied high-performance PM with a design speed of 1,400 meters per minute for SCA’s Obbola, Sweden, site, which manufactures 725,000 TPA of kraft liner with basis weights between 100 and 200 gsm.

Mr. Gustaf Nygren, Mill Manager Obbola at SCA, shared, “The journey for SCA and Voith together has only just begun. We have a long-term partnership in place with the target of reaching the common vision of PM 2 in Obbola becoming the new reference for safety, efficiency, and digitalization.”

Watch: JMC Paper Tech Launches New Subsidiary JMC Papers

SCA is using more than 10 innovative digitalization and automation solutions across the entire paper machine from the Papermaking 4.0 portfolio of Voith and its subsidiary. The company is using solutions from the OnEfficiency family to help increase line efficiency and stabilize product and process quality, and applications from the OnCare family to monitor productivity and take optimization measures quickly. The machine availability is further increased by digital services such as OnCall.Video remote maintenance service. Furthermore, the Voith Paper Webshop enables fast ordering of spare and worn parts as well as services. The digital portfolio is made available on Voith’s IIoT dataPARC cloud platform, which is characterized by the highest security standards.

Mr. Niclas Ahnmark, Paper Mill Manager at SCA, commented, “With the PM 2, we will take our next steps in the digitalization journey. The applications provided by Voith will help us to monitor the process and make the right decisions.”

Also Read: Suzano to Reduce Market Pulp Production by 4%

SCA has also signed a long-term service agreement with Voith subsidiary BTG for process control. BTG’s Lifecycle program ensures optimal consistency accuracy and control by providing preventive maintenance services for the entire consistency sensors install base, including regular calibration and routine checks. BTG Field Service Engineers assist in the planning, implementation, and coordination of the various maintenance services, maximizing machine uptime and stability while maintaining SCA’s high safety standards.

Mr. Stephan Sicking, Vice President of Sales FRS EMEA at Voith Paper, said, “As part of a digitalization roadmap, we have defined common goals and KPIs in a cross-functional team, developed a customized concept, and are now providing support for successive installation and employee training. Already, the benefits from this collaborative approach are clearly demonstrated.”